Peaceful Coexistence: Can Hydraulic Actuators Play Well with Others?

By Carl Richter, Vice President and General Manager, Kyntronics.

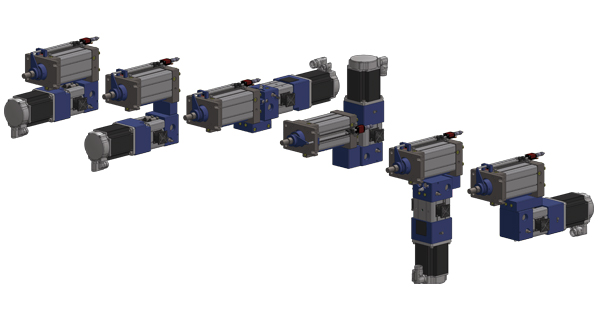

Configuration variations easily adjust to fit a machine’s orientation.

Hydraulic and electric actuators, despite their benefits and challenges, each have a place in the fluid power industry. Hydraulic actuators have replaced some EMAs — electromechanical actuators. Some EMAs have replaced hydraulic actuators. EMAs are typically used for relatively small, sophisticated applications, while hydraulic actuators are used in applications that range from small and simple to large and complicated. Some applications require more power than an electromechanical solution can provide. An ideal actuation solution may be a combination of both technologies.

Industry continues to search for process improvements to increase quality and throughput. Other actuation trends include smart actuators with onboard sensors and electronics for better control and data handling. The trend today is toward smarter devices.

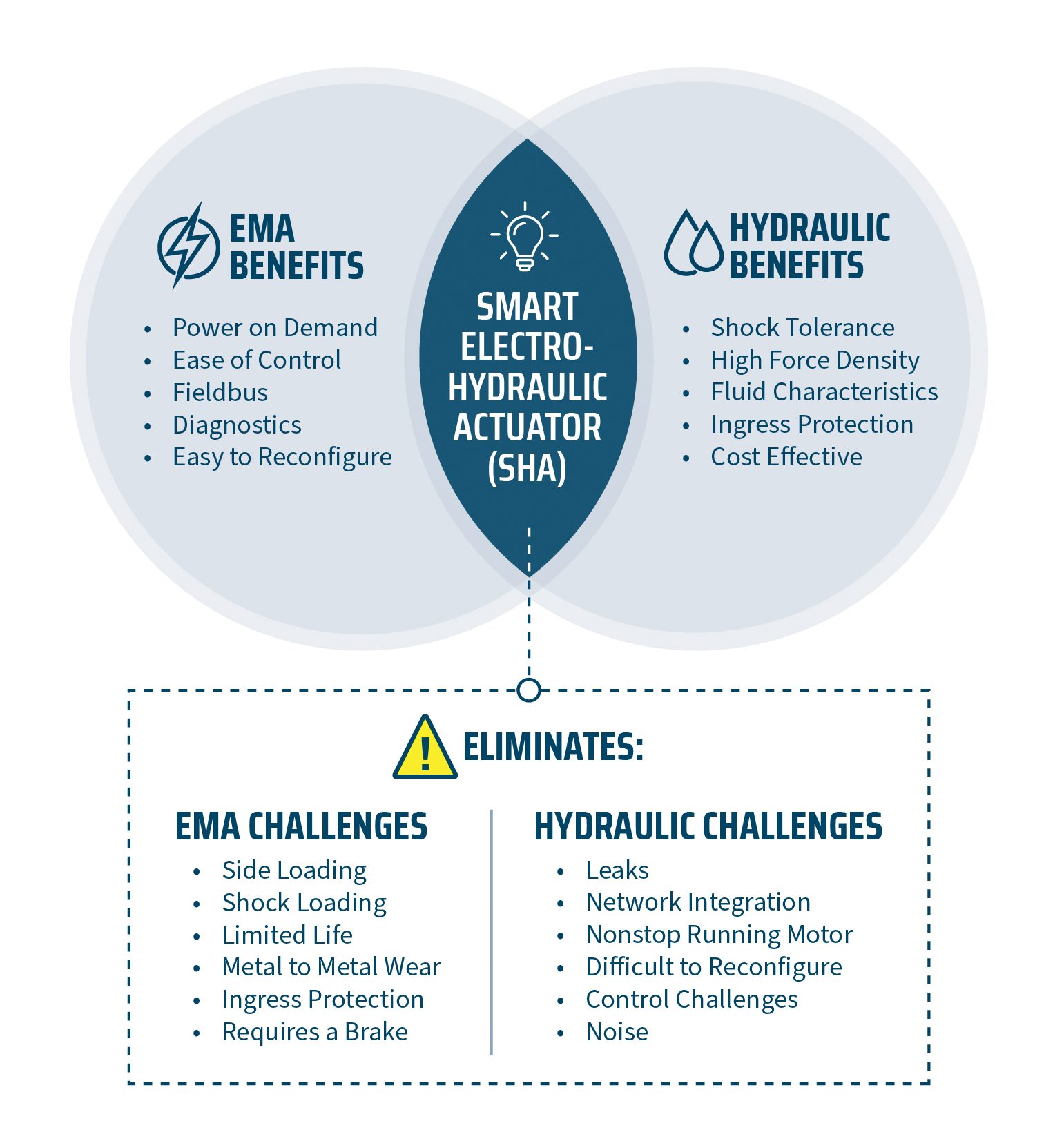

A quick comparison highlights some of the benefits and challenges of hydraulic and EMA technology.

Hydraulic advantages include:

- High power density.

- Multiple pumps and regenerative circuits permit the transmission between high speed–low force and low speed–high force.

- Overrunning loads can be controlled by a simple counterbalance valve.

- Relief valves limit force and work as protection devices.

- A float circuit allows a cylinder or motor to float or freewheel.

- Check valves can lock an actuator in position.

- Easily achieves fail-safe conditions with a spring or pressurized chamber.

- Handles shock loads.

- Maintains constant linear or rotational force.

Hydraulics also has its challenges, including:

- Potential environmental impact.

- Sensitivity to contamination.

- Design and installation time.

- Prime movers that must run continuously.

- Need for continual maintenance.

- Poor efficiency.

- Difficult to synchronize multiple actuators.

- Network connectivity is complicated.

Articles and webinars have focused on changing complete hydraulic systems to electric ones. The reasons to move to electric includes better control, connectivity, and efficiency. But electromechanical screw-based actuator systems cannot compete with the power density of hydraulics.

Every technology has its pros and cons, and electromechanical actuation is no exception. EMA advantages include:

- Power on demand.

- Overall efficiency.

- Fieldbus connectivity.

- Smart diagnostics and preventive maintenance.

- Simplified configurations and installation.

- Accurate and simple control with basic PID.

- Easy electronic synchronization.

There are many electromechanical screw-based actuators today, and they are ideal in less harsh environments. They work in applications that require sophisticated control and connectivity. They have lower force requirements, < 4.4 kN (1,000 lbf), along with higher speeds. Like any product, EMAs have their limitations. They can be expensive and relatively large with loads above 22.2 kN (5,000 lbf). They must be sized to distribute the forces and require continued maintenance and lubrication. Other challenges with EMAs include:

- Fragile mechanical components.

- Metal-to-metal wear.

- Decreased lifespan with increased loads.

- Failure on shock loads.

- Intolerance of side loads.

- Requires a brake to hold a load.

- Position feedback devices may have many mechanical components between the motor and the rod, resulting in backlash.

- Low dynamic contamination ingress protection.

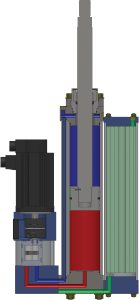

The pros and cons of hydraulic and screw-based actuators are well documented. Engineers are solving these problems as best they can. But a technology exists that combines the benefits of hydraulic and EMA technologies and eliminates their challenges: the SHA – servo hydraulic actuator, also called the smart hydraulic actuator. The SHA incorporates all the advantages of hydraulics and the electric screw-based actuator without hoses, leak points, or metal-to-metal wear. The technology is simple; a servo motor connects to a reversible fixed displacement pump and then couples to a hydraulic actuator. Changing the rotation or speed of the servo motor changes the direction and velocity of the actuator. The actuator fills with hydraulic oil and is sealed. There is no tank or external reservoir. The motor controls position, force, and velocity with simple PID control.

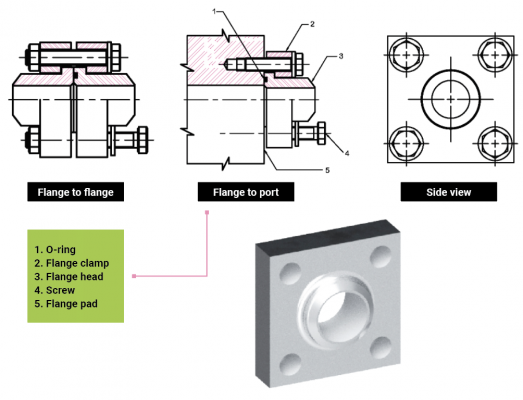

The internal operation of the SHA.

What’s in a name?

The SHA was originally called an EHA – electrohydraulic actuator. The technology has been around for many years. Its genesis may have been the desire to minimize the size of hydraulic systems on aircraft and move to a “fly-by-wire” solution, with aircraft being fitted with standalone, redundant EHAs. Many of these aircraft continue to fly today. The EHA concept has evolved considerably with the introduction of hydraulics.

The SHA acronym now used throughout the industry may lead to some confusion. It can be an abbreviation for servo hydraulic actuator or smart hydraulic actuator. To add to the confusion, a servo hydraulic actuator is sometimes called a servo-controlled actuated valve. Use caution when researching a solution.

SHA technology is still unknown to many professionals. OEMs and end users have found the technology beneficial and a differentiating solution. Some appliance manufacturers specify the SHA on new machines instead of the traditional hydraulic power unit. The limitations are with the pump size as well as the motor size. The SHA is not a solution for large (>700 kN (80T)) applications. Connecting a 75 kW (100 hp) motor to a standalone actuator is not practical.

The ability to combine servo control with hydraulics provides many benefits. It eliminates shock issues. The position sensor couples directly to the rod, versus on the encoder in a screw-based solution. Basic control theory states that the closer the feedback device is to the item being controlled, the better the overall control.

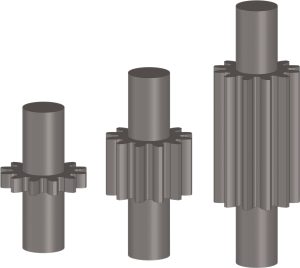

The SHA’s gear sizes adjust speed.

The SHA is the smartest actuator solution on the market. It includes position, force, and temperature sensors. A simple pressure sensor (F=A*P) measures force, and magnetostrictive technology controls the position of the SHA. Four-quadrant control provides both positive and resistive torque to the servo motor, eliminating the need for flow controls and counterbalance valves. With the SHA, accurate four-quadrant control is simple with standard PID logic. Actuator synchronization with hydraulics is also a major challenge, but with the SHA it is not a problem. You can use four SHAs on a four-post press, and they can synchronize holding position regardless of any offset load.

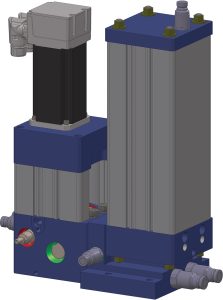

Other benefits to this hybrid product include power on demand and the software for a power-unit-only section to control a cylinder via two hoses. Some machines do not have the room for an SHA or EMA. With some simple hose connections, the machine can have the smart actuation solution, including accurate control, connectivity, and efficiency. While this solution uses hoses, with the SHA, the system moves fluid smoothly using S-curves and controlled ramps. Some hydraulics slam valves on and off with violent transitions that lead to leaks. Various SHA manufacturers have provided power unit solutions. Kyntronics’ power unit solutions are unique to each specific application and customer. When one unit required a float condition, we added a float circuit to allow the customer to easily move the cylinder when power was off. Others required locking solenoids; simple movement with an overriding load that was solved using a counterbalance valve; and simple up-and-down motion with no valves. Combining the electric servo and hydraulics eliminated continuously running HPUs, additional hoses, and leaks while providing a simple drop-in solution to an existing customer’s cylinder.

Being able to move fluid around, the SHA can be configured in many ways, some standard and some yet-to-be imagined. EMAs only have a few configuration options due to internal mechanical connection limitations.

Because it can move fluid along different paths, a high speed–high force transmission has many advantages. Another technology solution involves two cylinders in one actuator, one for high speed and one for high force.

A power-unit-only.

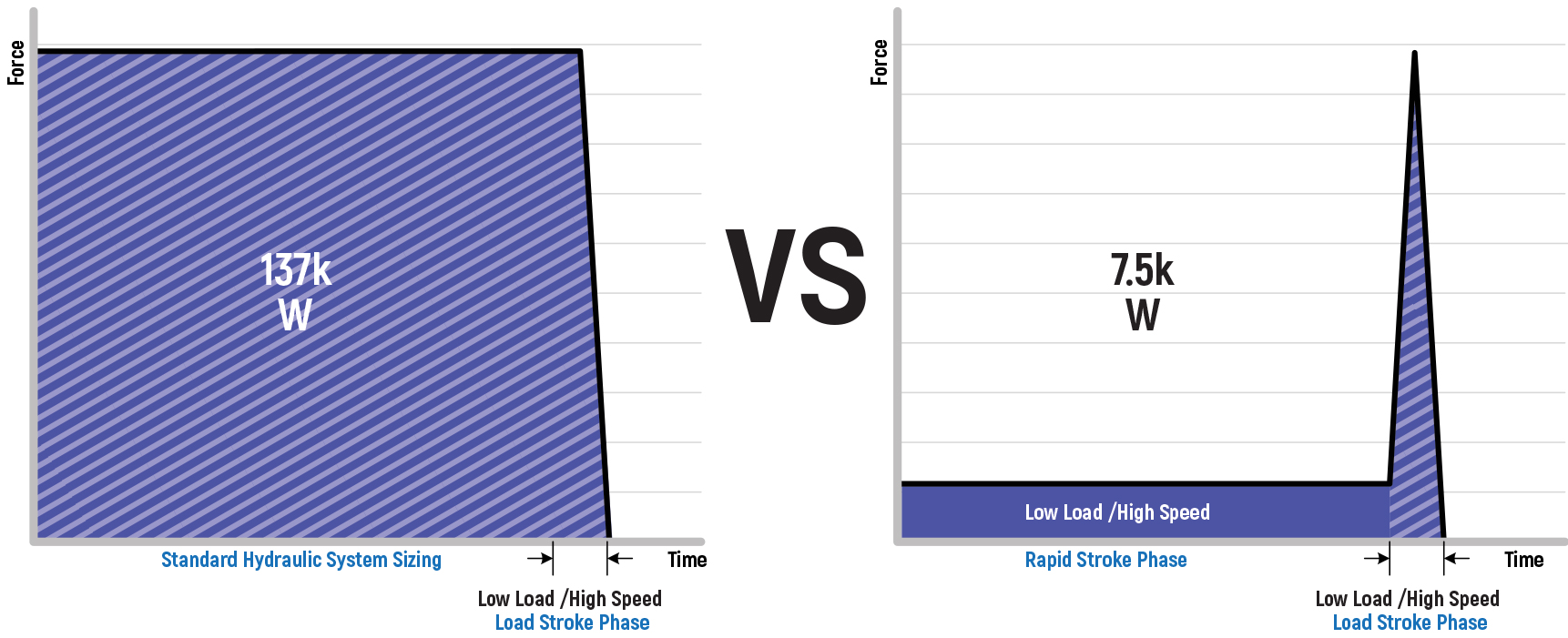

In applications like filling tires, a press, or high-force clamping, high speed–low force moves for most of the stroke then transitions to high force–low speed for a small portion of the stoke, usually close to fully extended. A small motor could accomplish this, when an HPU or mechanical actuator would need a large motor. The SHA can switch from high speed to high force at any stroke and achieves four-quadrant control for both force and speed.

Kyntronics’ SHA technology has developed product lines around combinations of hydraulics and electricity.

One can also take advantage of the additive fluid characteristics of hydraulics. Kyntronics completed a project in which a customer’s cylinder required significant load and speed. Our standard product provided the load but at a fraction of the required speed. We designed a system that combined five power units and achieved the necessary speed. The system also made each power unit independent and interchangeable. Each could be added or removed for redundancy purposes (another fluid feature). The customer benefited from an additional manually operated power unit. The manual power unit included a small pump that runs using a hand drill in a failure condition with the power out.

Kyntronics can provide an actuator-only solution, but we usually provide the all-in-one solution. The all-in-one solution includes the actuator, motor, and drive mounted and wired to a panel with standard software loaded and tested to the specifications. The customer does not need to select the appropriate motor or drive or set up control loops. The software provides several modes of operation, including position control, force control, and position with force limiting. The system seamlessly transitions between position and force control. The all-in-one also calculates the required regen energy based on tool weight. We install the appropriately sized dynamic braking resistor in the panel or enclosure. Instead of using a heat-generating counterbalance valve, which is difficult to accurately control in regen, a DB resistor provides smooth, accurate control throughout the motoring and regen parts of the profile. The software also allows easy-to-use AOI for a Rockwell Automation integration. The Kyntronics team is well versed with Rockwell products and has provided hundreds of their actuator solutions.

Hydraulics and electric screw-based actuators each have their advantages. Several unique product lines combine these technologies while eliminating their challenges. The SHA provides significant differentiating benefits and is a sustainable solution for the future.

The typical profile of the high speed-high force actuator shows kW savings.