Manufacturing Quality Parts While Protecting Workers’ Lives

By Michele Baker Thomas, Ph.D., Business Manager, York Precision Machining & Hydraulics.

Many of the parts in the vehicles we drive are made using molds in stamping, forming, and injection-molding presses. Any movement of the mold during the forming operation could result in a damaged or ruined part. Concern for operator safety is also a major concern when designing or implementing these machines.

In this article, we will address both the performance and safety issues.

Achieving “Zero Movement” in Manufacturing Presses

Why is zero movement important in producing a good part? Movement at the outset of the forming process may leave excess material along the edge of the molded part that must be removed, adding time and cost to the manufacturing process. Likewise, movement at any time during the forming process can ruin the part. Most load-holding devices in forming presses cannot achieve zero movement.

The Safety Factor

An automotive stamping or forming press is a massive machine with forces in the range of 13,300 kN (1,500 tons). Devices that depend on hydraulic pressure to remain locked are at high risk because there is always the potential for loss of hydraulic pressure. It could be the result of power failure, operator error, or component failure. If a press brake relies on hydraulic pressure to remain locked, loss of pressure represents a life-threatening danger. In addition to the incalculable loss of human limb or life, failure to provide proper safety features can result in costly fines or even the closing of operations.

The Solution

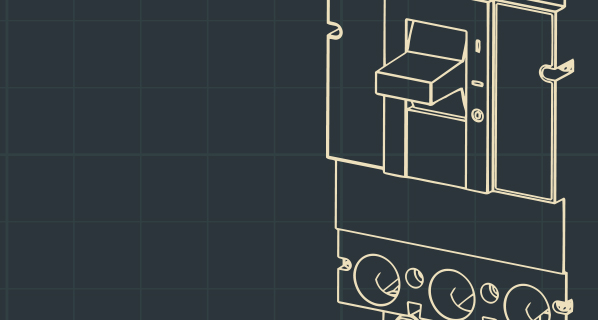

Whether pressure is lost on command or by accident, the Bear-Loc system engages automatically and instantly without delay or movement. It will hold the load without movement until hydraulic pressure is applied. When hydraulic pressure is removed, workers can safely operate and maintain presses.

Another Bear-Loc distinctive: infinite position. The rod can be engaged by the lock in any position along its stroke. That’s perfect for many applications. For presses, platen adjustment requires infinite position mechanical locking under heavy load cycling.

Two Customer Stories

One of our automotive customers has five Bear-Locs placed on each corner and in the center of a press that stamps automotive bumpers, five at a time. The Bear-Locs hold the platen in place without any backlash. (Backlash, sometimes called “lash” or “play” is clearance or motion in a mechanism caused by gaps between the parts.) Hydraulic cylinders lacking zero backlash capability could move and potentially ruin the part or cause costly rework.

If your processes require locking with zero backlash, make sure the components you choose are qualified for the job. These products feature zero backlash. They deliver no-motion reliability in any direction when engaged and operated within their rated capacity.

Operations Which Necessitate Injection Presses

Injection molding machines, also known as injection presses, make plastic and vinyl products we use daily. Generally consisting of three parts, an injection unit, mold, and a clamping unit, these machines produce parts for a variety of industries such as automotive, packaging, electronics, toys, appliances, and medical devices.

Hydraulic clamps are often used, particularly when fast tool changes are required. The clamp cylinder can be oriented horizontally (HCIMMs) or vertically (VCIMMs) and holds the mold closed so that the injected material can be accurately formed. The injected material exerts a tremendous force that acts to separate the parts of the mold. The Bear-Loc holds the mold together, ensuring a quality part.

A positive locking capability means that the device will not move or shake loose when locked. This patented design is based on the principle of the elastic expansion of metal under pressure. Simply put, the unit locks when hydraulic pressure is intentionally removed or accidentally lost.

In addition to infinite position capability, device also has bi-directional locking power. The rod can be engaged by the lock in any position along its stroke, and motion is impossible in any direction when the lock is engaged and operated within its rated capacity.

Additional features included for both new and existing equipment:

Design simplicity. Does not depend on moving parts, valves, or other components to obtain its positive mechanical lock.

Design simplicity. Does not depend on moving parts, valves, or other components to obtain its positive mechanical lock.

Wide range of configurations. Are available in a wide range of configurations such as linear actuators, linear units, and rotary units, all available in both tie rod and mill type constructions.

Wide range of configurations. Are available in a wide range of configurations such as linear actuators, linear units, and rotary units, all available in both tie rod and mill type constructions.

Engineering design. Designed specifically for the customer’s application. Every system is tested and certified to meet the customer’s application requirements.

Engineering design. Designed specifically for the customer’s application. Every system is tested and certified to meet the customer’s application requirements.