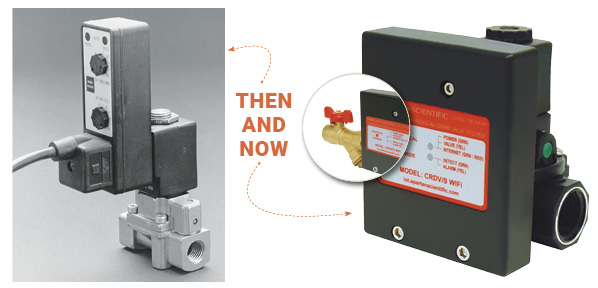

Then and Now: CRDV, CRDV/S, and CRDV/S with WiFi

By Patrick Byce, Marketing Coordinator, Spartan Scientific

The Journal is celebrating a 25-year milestone in 2019 and reflecting on how far the industry has come since the birth of the magazine. This new column is dedicated to showcasing the growth of fluid power technology. Each article features a product and how it has transformed from its early years. If you have a product to share with the Journal readers, please contact Candace Nicholson at cnicholson@fluidpowerjournal.com.

Spartan Scientific, an American manufacturing facility located in Northeast Ohio, specializes and builds fluid control products within the automation industry. Spartan has learned through their many years of experience that, not only the automation industry, but all industries are constantly evolving. New ideas accompanied by new innovations and technologies are regularly assimilating into different types of businesses and manufacturers as efficiency, productivity, performance, and cost savings continue to stay at the forefront of nearly every industry.

Air Compressors are used every day within an incredibly diverse range of industries—industries that are all striving to be more efficient, proficient, and economical. Today, we see that air compressors are core components of engineering, manufacturing, construction, agriculture, mechanical work, factory assembly lines, transportation, and many more. A common characteristic of all air compressors is the natural accumulation of water. In fact, water accumulation contributes to a majority of problems and maintenance issues within many industries. Those who have experience in engineering and construction are likely to be aware of this.

One of Spartan Scientific’s first products developed was the Series CRDV, also known as the “Condensation Removal Drain Valve.” When Spartan Scientific came into existence back in 1987, they were fully aware of this age-old problem and understood what kind of consequences would transpire if the natural buildup of water began to overtake an air compressor and its air lines by not being drained frequently or correctly. By addressing the problem of excess water, the Series CRDV Condensation Removal Drain Valve dramatically improves the life of air compressor systems, which leads to increased efficiency, productivity, and cost savings. The Series CRDV makes it so that the water accumulation can be drained and removed at any point within an air system, using a solid-state timer and a proven solenoid valve operator.

As technology has evolved, Spartan Scientific continued to make positive changes to keep up with their customers’ changing requirements. The Series CRDV has proven to be a great product, but there were ways to increase efficiency even more. The Series CRDV will drain water build-up after a set amount of time, which means that certain conditions, such as low humidity, would generate much less water than normal to high humidity. This would cause the Series CRDV to open up and purge the compressor regardless of the amount of water present in the air compressor. Purging more often than necessary causes air loss within the compressor system. Over time, air loss will add up and lead to a loss of substantial amounts of money.

To combat this problem, Spartan Scientific developed the Series CRDV/S in 2008. This enhanced drain valve took the same underlying principle of draining water build up, but made it so that the process would not cause a compressor system to undergo unnecessary air loss. The key component within the Series CRDV/S is its self-learning mode that will open the valve to drain only when it senses the presence of water. Other features of the CRDV/S include a 24-hour self-cleaning cycle, status indicator lights for easy maintenance, and an environment-resistant design.

In 2019, Spartan Scientific will be releasing an enhanced and more evolved version of their Series CRDV/S. This version is a WiFi-enabled drain valve that uses IoT (Internet of Things) technology. When asking Spartan Scientific’s Chief Engineer Phil Muntean why IoT technology would be an important feature to potential consumers, he explained: “It’s the freedom. There are no boundaries and you don’t have to be restricted to your facility to monitor any of your equipment. You can be at home sitting in your living room watching television and view real-time data that tracks any type of unusual behavior or inconsistencies that your systems might be experiencing. Imagine receiving an email or text message alert, sent directly to your phone, that notifies you that your system is acting erratic or that it may need your attention soon. The IoT CRDV/S drain valve will be able to prevent problems before ever happening.”

The idea of IoT technology might be new to some, but manufacturers, businesses, and organizations alike are using IoT technology in a diverse variety of industries to operate more efficiently with higher cost savings and to better understand their customers, which in turn will enhance customer service, improve decision-making, and increase the value of their business.