Oilgear Products for Subsea BOP Systems

Oilgear recently released two products for blow-out preventer systems in subsea applications.

Oilgear recently released two products for blow-out preventer systems in subsea applications.

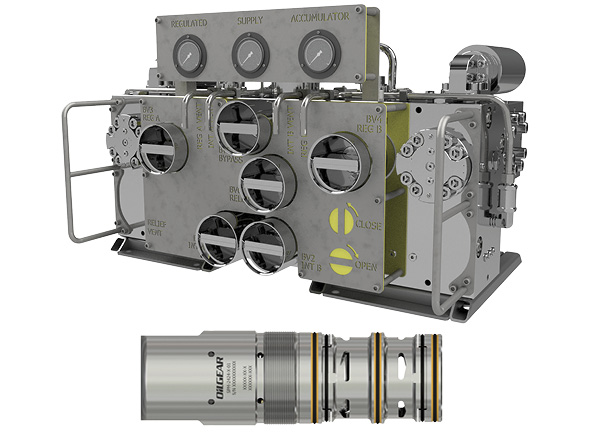

Oilgear’s subsea all-hydraulic boosting and regulating system (BARS) needs no electronics or special control features. The BARS unit allows drilling contractors to use the full working pressure in existing subsea accumulators, effectively storing the extra energy required for optimal use of the blow-out preventer (BOP) system.

The proprietary intensifier pumps boost the pressure from the surface to a maximum of 7,500psi to provide accumulator supply pressure. When the BOP control system has a demand for fluid, the high-flow regulator on the BARS unit regulates the pressure back down to the maximum working pressure of the control system. Because the operation of the BARS unit is fully hydraulic, no electrical signals are needed. Once fluid is supplied to the inlet, or consumed from the outlet, the BARS unit will begin to operate until a system equilibrium is created.

The benefit for drilling contractors is that the unit maximizes the pressure capacity in accumulators without increasing the pressure of the existing piping and hydraulic system. The BARS unit can be retrofitted onto any BOP stack and is simple to install. It bolts onto the BOP and easily connects with only three hoses. The unit is a fraction of the weight and cost of adding more accumulators.

The BARS unit is available in various pressure and flow-rate configurations, and it can accommodate all BOP fluid types.

Oilgear also released a new directional valve for BOPs designed for extreme conditions in the deepest ocean floor environments. The high-performance SPM valve provides critical function control for subsea BOPs thousands of feet below the ocean surface.

The valve is sold as an aftermarket replacement component that can drop into existing BOP platforms and fits into nearly every OEM system available.

Oilgear’s engineers designed the SPM valve to operate consistently in extreme subsea conditions. The valve seats are designed with Oilgear’s proprietary hard-seated design. They can withstand higher pressure and more cyclic loading than current SPM valve seats. The unique seat design and high strength of the hard seats allows the SPM to handle water hammer and pressure spikes from BOP functions. The seats are also strong enough to handle a full 5,000 psi in the pilot circuit.

The low crossover flow design has a metered valve opening that reduces interflow out of the vent during shifting, reducing energy and shock in the system when the SPM shifts. The use of electro-polished, corrosion-resistant materials means the valve won’t prematurely corrode in the harsh seawater environment.

The one-piece design has fully replaceable poppets, and its seats do not require lapping or special processes to be leak free.

For more information, visit www.oilgear.com.