Ok, I Admit It. I Made A Mistake.

It has been my focus to design energy efficient Fluid Power Systems. To me, every lost BTU or SCFM is a failure. I joke when seeing large heat-exchangers that it is like seeing work done by a carpenter who uses 12 inch trim. The heat-exchangers cover up a problem, addressing the symptom but not the cause. In many instances this is true but I was still ignorant of another major factor in providing the most efficient Fluid Power systems.

It has been my focus to design energy efficient Fluid Power Systems. To me, every lost BTU or SCFM is a failure. I joke when seeing large heat-exchangers that it is like seeing work done by a carpenter who uses 12 inch trim. The heat-exchangers cover up a problem, addressing the symptom but not the cause. In many instances this is true but I was still ignorant of another major factor in providing the most efficient Fluid Power systems.

If you are a Certified Fluid Power Professional (and if not, why not?) you certainly see a problem with a hydraulic system using a fixed displacement pump and a relief valve for speed control or a pneumatic system using unregulated pressure and only meter-out flow control. However, we, the professionals, have others somewhat at our mercy. We understand the “black box” of Fluid Power. They only want to move their stuff from point A to point B and have chosen Fluid Power as the means to do the energy transfer.

We sometimes tend to provide systems based on habit and convention as well as what may be in inventory. How often do we stop and look at the actual energy requirements and then design backward from that point? How often do we consider the fact that, even though we do not have to pay the energy bill for our customer, the cost to operate a Fluid Power system will have a direct effect on the way Fluid Power is viewed and will impact the future of our industry?

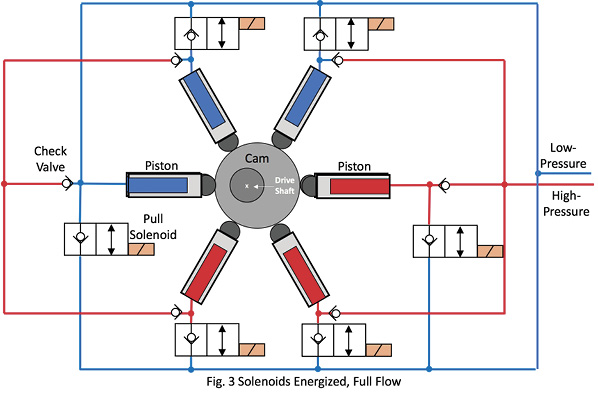

What is the most efficient Fluid Power System? It is one where the flow and pressure exactly match the energy transfer requirements of the system. More flow and/or pressure than is necessary will have to be unloaded in some manner as wasted energy.

Ok, Ok! I know all this stuff already. What’s all this about “I made a mistake”? What did I overlook?

All systems have a prime mover; most commonly an electric motor and this is what I have neglected. I have typically recommended systems that have; A) a larger than necessary motor, and B) that spend a lot of time in an idle mode. I did not pay attention to the fact that; A) electric motors are designed to operate most efficiently within 10% of the name plate power and; B) electric motors idle using about 30% of their full load amperage. Under utilized, a motor has a poor power factor that will affect the whole facility.

The use of variable frequency drives to help match electric motors to the load or a soft-start to allow the motor to be turned off during prolonged idle can make a dramatic difference in the energy used by a Fluid Power system.

I used to think of variable frequency drives as competition to Fluid Power systems. I now realize that VFD’s and Soft-Starts should be a part of our repertoire in providing the best of Fluid Power.