Optimizing Linear Motion Solutions Using Hybrid Automation Systems

Achieve greater efficiency, flexibility and more for complex equipment and processes by combining electric and pneumatic actuators.

By Florent Orget, Manager Product Marketing for Actuators, Emerson

There are many technical and commercial factors that original equipment manufacturers (OEMs) must evaluate when designing motion control solutions for industrial machinery. Many types of industrial machinery use motion control to carry out their functions, and some of the most popular technologies that OEMs depend on for linear motion control are pneumatics and electrical linear actuators. Motion control may be initiated manually by operators, or automatically via advanced control platforms.

When designing automation systems, OEMs have historically had to choose between motion control technologies. Pneumatic and electric motion each have their strengths. Pneumatic motion is seen as robust and easy to use and maintain. Electric motion is perceived as smart, quick, and precise. OEMs have had to select the technology based on which would be most beneficial to an application; in some applications, key needs were sacrificed in favor of others.

Processes and application priorities have evolved. Sustainability is today’s top priority in almost every industry, while operations have become more complex and require more precise, efficient motion. Functions are consolidated into smaller spaces with fewer components. Another important component has changed, too. OEMs no longer have to choose only one technology. There are hybrid automation systems that combine the strengths of pneumatic and electric technologies to provide the greatest benefit for complex motion control applications.

Trends Driving Hybrid Automation Systems

Some OEMs may wonder why there’s a need for electric linear motion in addition to pneumatic. By recognizing several trends driving the evolution and use of hybrid automation systems, we can better understand how cross-technology solutions emerged. Sustainability, digital transformation, machine design, and competitive pressures collectively influence its popularity.

Sustainability

There’s an increased focus on energy consumption, carbon emissions, and cost savings across industries. A sense of personal responsibility, customer demand, government regulations, and stakeholder pressures fuel this focus, and many corporations are making commitments and long-term goals based on ambitious net-zero initiatives. Motion control systems that use less energy and can be powered by renewable resources are key to energy-efficient equipment and are part of a sustainable corporate strategy.

Digital transformation

Today’s manufacturers interact with digital automation and detailed user interfaces in their daily lives and expect the same digital capability from industrial systems. As companies digitally transform their operations, they’re seeing real, reliable benefits. Embedded sensors in devices continuously track temperature, position, load, and wear in real-time. Monitoring, automatic configuration and diagnostics, and collected process data presented in dashboards give operators the insight they need to make confident, informed decisions. Connected motion control systems enable operators to analyze production performance, energy use, and reliability. Access to these insights via dashboards empowers manufacturers to refine control, improve operations, and, ultimately, their production.

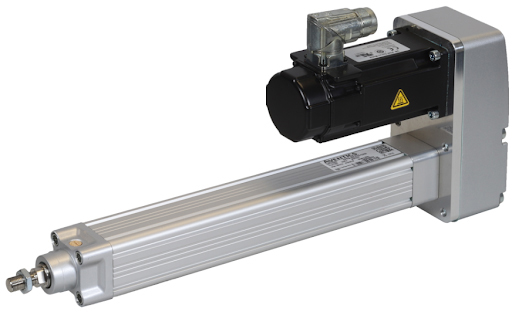

Emerson’s AVENTICSTM Series SPRA electric rod-style linear actuator offers the enhanced load capacity, accuracy and reliability that manufacturers need to maximize productivity.

Market competition

Between labor shortages and supply chain issues, it’s never been more challenging for companies to maintain a competitive edge. Additionally, the digital transformation of industrial manufacturing and the advanced technologies driving it made it possible for companies who invest in them to optimize their operations. The need to remain agile when responding to changing market needs and reliably meet customer demand has increased to ensure companies stay on the leading edge of the market. Manufacturers must minimize machine downtime and maximize production. Incorporating connected hybrid automation solutions can help improve machine reliability and uptime.

To optimize energy use, enhance operations, and stay ahead in their industries, companies are looking for a complete motion control package. Leading technology suppliers understand this and have developed a range of advanced, integrated solutions that combine servo drives, motors, electric actuators, and pneumatics. OEMs have a significant opportunity to incorporate hybrid automation systems in machine designs that align with and address their customers’ greatest needs and concerns.

Automation and contemporary machine design

One way that companies overcome challenges and increase production is by integrating smaller, more sophisticated machines into their production lines. Smaller footprints allow more machines to fit in the same production space, and advanced motion control technology makes it possible to automate higher-precision tasks from assembly to final product inspection. Manufacturers are also seeking motion control technology featuring increased accuracy to prevent waste along with shorter cycle times to increase output and greater position flexibility. This allows operators to change machine programs at the push of a button. Using machines with these features can result in higher production in less time, as well as improve sustainability and reduce costs.

Pneumatic solutions provide robust operation in many different applications and usually have fewer components to change or replace when upgrading a pneumatic system, compared to a servo system.

Cross-Technology Automation:

Selecting Pneumatics and Electrics

There are many motion control offerings available, and it may be confusing to know how to choose among them. When do OEMs use electricity, when do they use pneumatic, and when do they use both? There are many factors and concerns to consider when selecting motion solutions. Do they meet the application’s performance, flexibility, and accuracy requirements? What are the initial operating and continued maintenance costs? How do they affect the energy efficiency of the machine? How will motion products integrate with other devices? Can they collect data and analyze device health? Will they make it easier and faster to design a machine? What’s the learning curve for new technology?

Pneumatic and electric motion control each have distinct advantages, depending on an application’s needs, and an application may benefit from one or both. For some applications, it’s clear which is the best fit. For a simple mechanism to push boxes off a conveyor, a pneumatic cylinder makes the most sense. However, if these boxes need to be sorted to different lines or positions on the conveyor, an electrical actuator with multipositions is required.

In more complex applications, the choice may be unclear. This is one sign that applications may benefit from using both. Electromechanical cylinders can use compressed air via a pneumatic connector to seal air in filling applications. In assembly systems, an electric linear multiaxis system can use a pneumatic gripper. An electric linear axis operating in a vertical direction can use a pneumatic cylinder for weight compensation. Cross-technology automation allows OEMs to harness the complementary strengths of both pneumatic and electric motion control technology in the same application and pass the benefits on to their customers.

Let’s look at the strengths of each technology to better understand how they can work together:

Pneumatic Motion Control

Pneumatic motion is achieved by using compressed gas to physically act on a mechanism to produce the required motion. Pneumatic solutions provide robust operation for hardware, design, and installation. There are usually fewer components to change or replace when upgrading a pneumatic system versus a servo system.

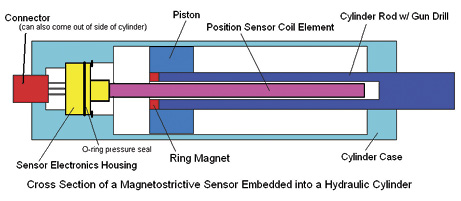

The most familiar example of pneumatic motion control is a cylinder with an internal piston, which produces linear motion. This contributes to pneumatics being classified as a discrete motion technology primarily useful for fully extending or retracting a mechanism. Continuous innovation, driven by motion control technology suppliers, has expanded what is possible. For example, continuous rotational motion can be achieved using quarter-turn actuators. Sensors and flow controls are available to monitor and optimize operation, while differential pressure controls make it possible for equipment to achieve continuous pneumatic positioning. Using relatively small electro-pneumatic on/off solenoid valves or modulating positioning valves, controlled pressure is applied against constant back pressure. Operators can control positions manually using buttons and switches. They may also automatically use a programmable logic controller (PLC) or loop controller.

Electrical Motion Control

Electrical actuators, combined with servo motors, are known for high speed, pinpoint accuracy, and efficiency. They achieve motion by converting electricity into rotational or linear motion. These closed-loop systems typically include more complex components than pneumatic motion solutions, such as a motion controller, servo drive, motor and feedback sensor, and design practices.

Each servo motor is associated with a drive that follows commanded signals, providing the desired function and delivering accurate positioning, precise angular velocities and variable acceleration profiles. With such a range, servo systems provide positional motion control for applications ranging from a robot arm to continuously rotating conveyors. Since servo drives and controllers are microprocessor devices, they have a high, innate level of on-board functionality and can directly offer local and remote diagnostic and data logging for dashboards.

The connection of PLCs and other controllers to servo motion systems can help OEMs accomplish even more advanced motion control and synchronization. Specialized functions include precise positioning with sub-micron repeatability, electronic camming and electronic gearing and can benefit the most complex applications, such as machining, robotics and manufacturing equipment. For example, a packaging line can upgrade from mechanical cam discs to a servo motion system with electric cam discs. This contracts with changing the format using mechanical discs, which is complex, time-consuming and subject to error. Machine conversion using electric cam discs happens at the touch of a button. This saves time, improves accuracy, minimizes scrap, and reduces costs.

Hybrid Motion Control

An electropneumatic hybrid automation system can help manufacturers apply suitable technologies for each specific function. When sustainability, position flexibility, precision, stability, quiet operation, connectivity, and monitoring capability matter most, electrical motion offers significant advantages. When applications have space limitations, demand robust operation or require quick design, installation and commissioning, pneumatic motion control is the best choice.

The production lines in most manufacturing facilities include various types of OEM equipment, with product moving between machines along transport and accumulation conveyors. These lines offer many opportunities to integrate both pneumatic and electric linear motion. For example, a typical beverage packaging production line includes the following functions: stretch-blowing molding bottles, fill and cap bottles, conveying and accumulating, labeling bottles, inspecting fill and label, packing bottles into cases, and palletizing and shrink-wrapping cases. Stretch-blow molding, folding boxes and applying glue all benefit from pneumatic motion, while conveying and positioning bottles within filler and labeling equipment benefits from servo motion. Simple transport conveyors and palletizing systems benefit from both forms of motion; conveyors can be driven by electric motors, and product stops and gates can operate using pneumatic actuation. Handling bulk cases can be achieved with pneumatics, while interpolation and fine position adjustments may be controlled using servo motion.

Advantages of Hybrid Automation Systems

Leading motion control technology suppliers now offer integrated, full-solution packages that include electrical, pneumatic or hybrid motion control. These comprehensive solutions feature intelligent devices at the field level, motion control, machine control and analytics. Pneumatic options involve a pneumatic cylinder, valve system, controller, analytics and dashboard via gateway, while electrical include an electrical linear actuator, servo motor and drive, controller and dashboard via gateway. While both technologies offer dashboards, data is available directly from the servo drive and pneumatic systems require the addition of sensors.

Complete, integrated solutions offer many benefits to OEMs and their customers. Since they’re already engineered and assembled, hybrid automation systems streamline procurement, development, and commissioning. Otherwise, OEMs must source components separately and match and engineer them themselves. Not only does this take longer and add complexity to the supply chain, it can introduce sizing issues.

Hybrid automation systems also offer flexibility that helps OEMs design machines that produce assorted product types, minimize changeover time, and meet changing requirements over time. As many companies face continued pressure to increase throughput while lowering operating costs, this can shorten production runs, increase machine utilization and extend equipment life. With motion control electronic reconfiguration, operators can change motion profiles on the fly, and some systems offer a future-proof design and features that can be implemented now or in future machine generations. To offer customers the highest level of flexibility, look for systems with extremely versatile electric actuators that cover a wide range of application requirements.

In addition to remaining competitive, hybrid automation systems can improve manufacturer sustainability. These systems can provide better machine efficiency and reduce scrap, which, in turn, lowers resource consumption and costs. Energy efficiency makes it possible to attain sustainability targets and reduce total cost of ownership. For greater repeatability and uniformity, it’s important to look for a system with electric linear motion that delivers the highest levels of reliability and accuracy.

Optimizing operations relies heavily on real-time data to present insights from pneumatic, electric or hybrid motion control solutions. These insights allow operators to monitor equipment condition and make informed decisions.

Greater Flexibility, Efficiency, and Performance

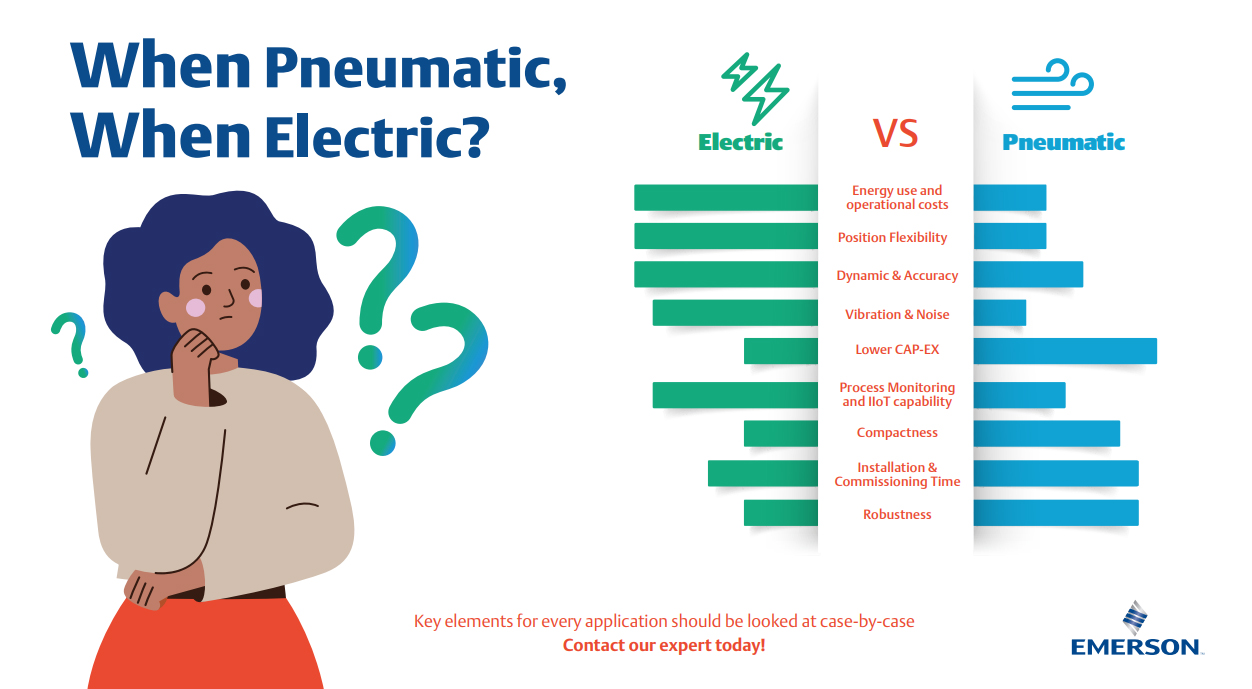

OEMs can determine if a hybrid automation system will benefit an application by evaluating key application factors, including energy consumption, operational costs, position flexibility, accuracy, vibration and noise, CapEx, connectivity, size, installation, and commissioning time and durability. To select the most appropriate solutions that achieve the desired results, it’s critical to work with an expert motion control and digital transformation partner with a comprehensive portfolio of technologies and sizing options. A partnership like this helps OEMs commission solutions and offer long-term support.

With hybrid automation systems, companies can have it all — precise, powerful linear movement, flexibility to meet changing production requirements, data and insights to maximize production, optimize energy consumption, and lower total cost of ownership.