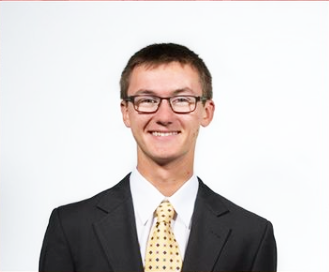

Profile: Bishwajit Ranjan

Why did you decide to work in the fluid power industry?

While pursuing my engineering, I never thought of working in fluid power. Incidentally, as a young engineer, I got the opportunity to work in a large steel plant project. During installation and commissioning of the plant, I was exposed to the application of fluid power for practically every equipment used for precisely positioning the product, controlling quality of the product through closed-loop automatic gauge and width controls, and generating high tonnage needed for deformation of slabs into thin strips. The experience of working in a fluid power application was very interesting, as it involved logical thinking and troubleshooting. Since then, working in fluid power applications was my natural choice. Very soon I became a “young” fluid power expert whom people would call whenever they had problems. While helping people solve problems gave me a sense of achievement, it also made me popular at a very early age.

How and why did you get involved in the IFPS, and what have you gained, personally and professionally?

I subscribed to the Fluid Power Journal in 1999 when I was working in India. The Journal has very good information about technical issues, industry data, and people who make the industry thrive, and I always felt connected with the industry through the magazine. I became seriously involved after coming to United States in 2008 when I worked as maintenance manager at JSW Steel USA Inc. With my involvement in the IFPS, on the professional front I added many good friends across the industry and gained respect within the organization where I worked, but most important, I have a sense of satisfaction in giving back my due to the industry through an organization like IFPS with its team of highly motivated and dedicated industry members.

How, when, and why did you decide to pursue certification, and how has it helped your career?

Although the application part of fluid power had always been my strong area and I had extensive experience in troubleshooting, I did not feel very well-connected with underlying theories and principles of fluid power. In 2014, one day I came across a certification manual that appeared to be very much relevant in connecting theory to application. The test sample questions were very challenging, but I started pursuing certifications. Before applying, I spent time understanding the whole process and set my goal as Certified Fluid Power Engineer (CFPE), which was a combination of three certifications and Board approval. After an effort of two years in 2015, when I was certified as one of Ellwood Texas Forge’s few CFPEs, the feeling of accomplishment was great.

While being certified makes people believe in one’s competencies, it also makes one feel responsible towards the profession, safety, and industry. Certification helped my career grow at a much faster rate. I was appointed as a fluid power instructor for a corporate technical development program for engineers to develop them as Subject Matter Experts (SMEs). I got involved in all the major projects related to fluid power equipment.

What have you learned by working in the fluid power industry?

Safety has no holiday, and there is no day when we do not learn. As fluid power professionals, we must strive for efficient performance of equipment. In the rare event of a catastrophic failure, if you examine the event deeply enough, you will find all the symptoms and an underlying cause. The challenge is to understand the symptoms and take corrective action well before the failure happens.

Where do you see the industry heading in the next 10 years?

With increased automation, safety, precision, and accuracy needs, the fluid power industry has a very bright future. In the coming years, however, safety, response time, and efficiency will be the most important attributes for fluid power components. Whether mobile or industrial, there will be more thrust on compact, lightweight, and energy-efficient pumps and motors. There will be more and more pressure on productivity to fulfill the higher volume, and the need for cost reduction will cause more pressure on reliable operation of the components.

What advice would you give someone just starting out in the industry?

Knowledge is power while working in the fluid power industry. Knowing underlying principles is also very important. While this knowledge boosts our confidence and makes us successful, it more importantly helps keep ourselves, our coworkers, and the public safe. Never, ever assume anything while working in fluid power. What you see, you believe.

What are some of your favorite hobbies or interests?

Hiking, bicycling, and reading books

What is something people would be surprised to learn about you?

I am an avid learner, and we have very little time to learn so much. Everyday I wish to have another hour to learn something new.