Proper Filtration is Critical to Your Operation

By Don Krause, Business Development Manager, Ohio Fabricators Company.

Proper filtration in hydraulic system design is a critical, yet often overlooked, component. Many times, filtration is inadequately and improperly planned for the system. However, in order to maintain a system that is operating smoothly and efficiently, adequate filtration must be designed into it. Simply said, if the filtration breaks down, the system will break down. According to Mark Redmond, a hydraulic systems engineer for Michigan-based MFP Automation Engineering (www.mifp.com), “over 75 percent of all failures in a hydraulic system are caused by contamination. If you can control the introduction of contaminants into the system, you will experience greater uptime and much lower expenditure for repairs and replacements down the road.”

When selecting filters, consider operating pressure, fluid compatibility, level of filtration required for the specific locations in the system where they are being installed, filter media and strength, and capacity. Where are the filters being installed? Suction line? Pressure line? Return line? For a smooth and efficient operating system, filter placement is critical. If you are not sure where the target critical locations are, you should contact a filter specialist.

MFP manufactures over 1,000 hydraulic power units a year and always includes specs for replacing components. According to Redmond, “it’s critical for OEMs and end users to follow our recommendations when replacing filters to ensure proper system operations.”

Filter sizing

Proper filtration is necessary if you want peak performance from your hydraulic system. There are a series of considerations to consider before filters are installed. Know and understand hydraulics and the application, as well as the requirements of its performance. Filter sizing can be a problem if you aren’t sure of the system operation and what its primary function is. The point is, you shouldn’t just remove a filter and install a new one in its place without making sure you have the correct filter to get the job done efficiently and effectively.

Here are some considerations when trying to ensure proper filtration. First, there are many different systems, performing many different applications, with many different requirements. Sizing a filter to a system is critical and could be the difference between a smooth-running operation and a poor one. Here are a series of questions that should be considered:

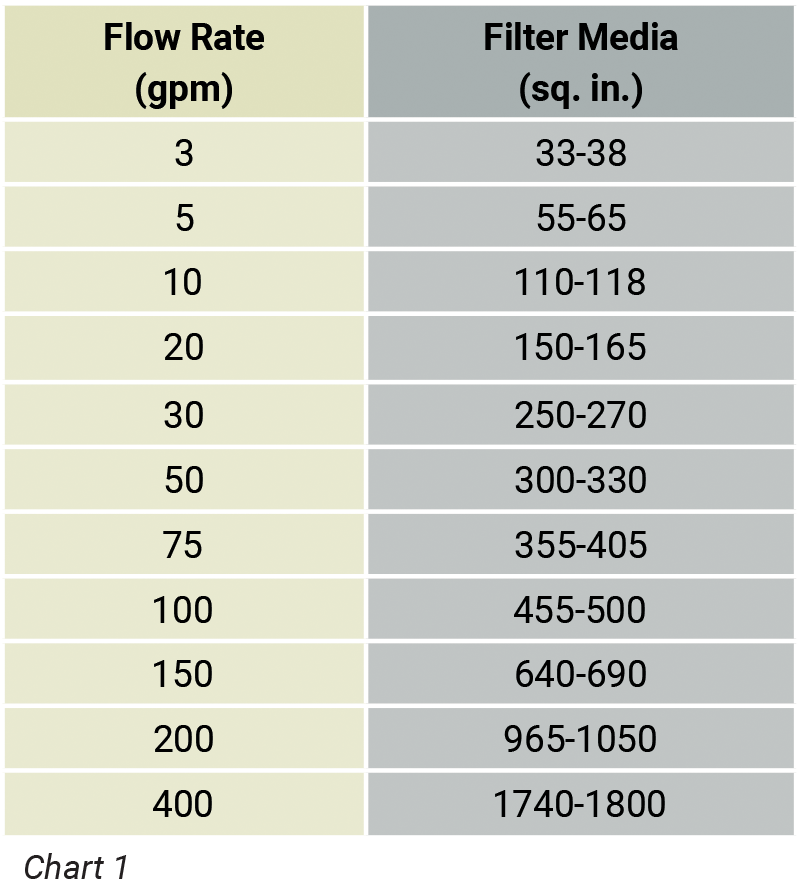

1. What is the flow rate of the pump? The first consideration is knowing the rate of flow of the process fluid. This would tell you how large or small the surface area of the filter media should be (sq. in.). See chart 1 below for an approximation of the size of the filter media and the corresponding flow rates. Most common suction strainers are made from 100 mesh (149 micron) stainless steel screens and operate at around 100° F.

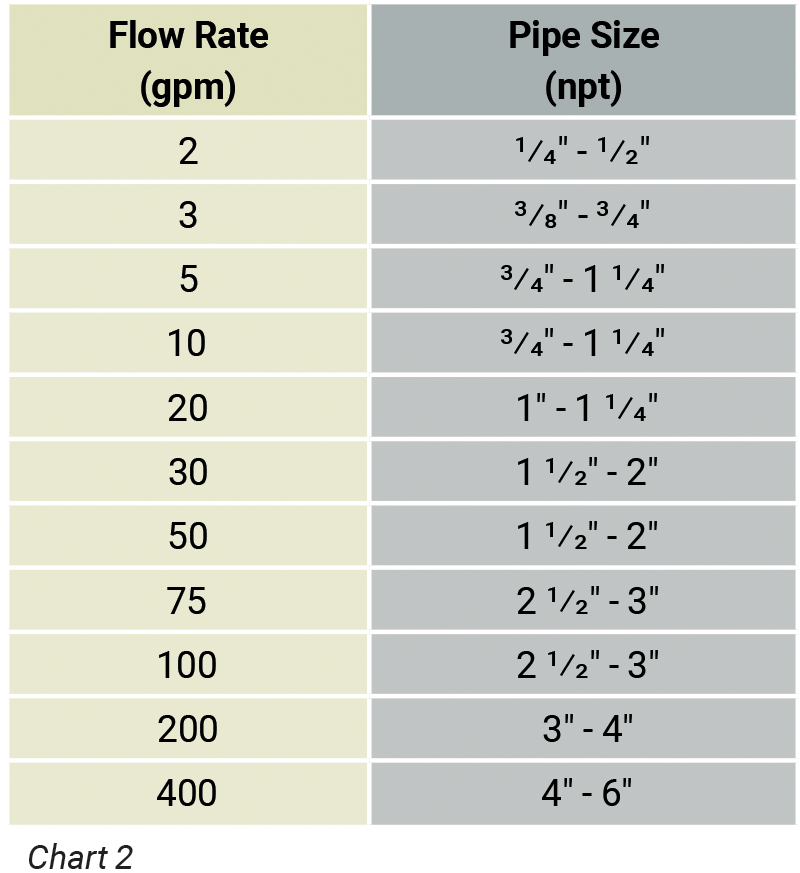

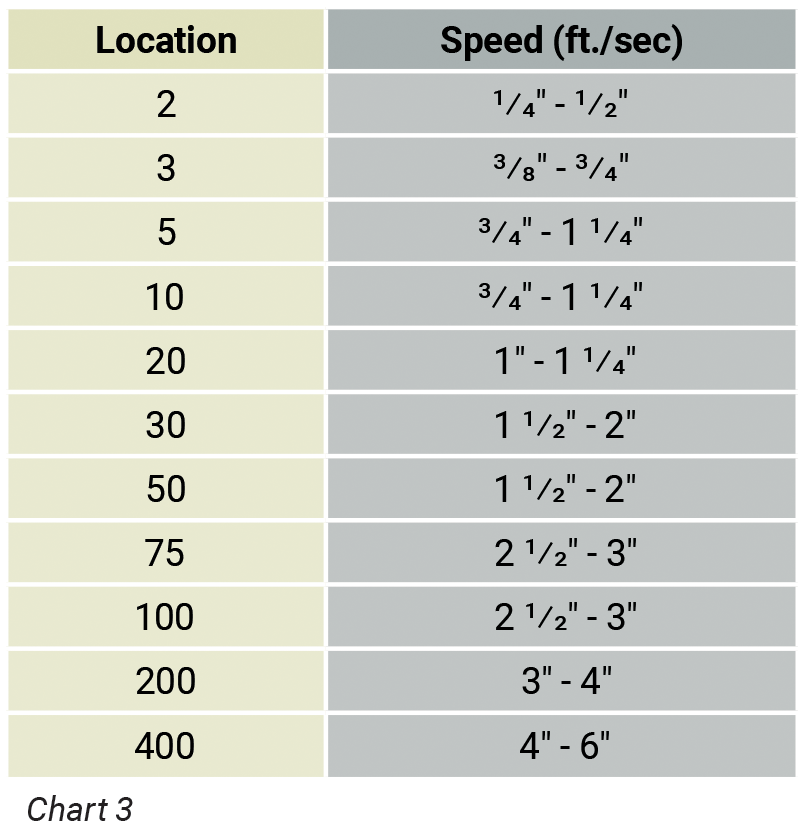

2. What is the pipe size? Flow rate and pipe size go hand in hand. If you have a flow rate of 50 gpm, the filter must be the correct size to keep the pressure drop in check. A pump creating flow of 50 gpm, for example, will have a lower pressure drop flowing through a 3” npt line, than it will a 1” npt line. Knowing the pipe size will narrow the options you have to adequately determine the correct filter size. A general reference, chart 2, follows for flow rate/pipe size sizing. “Typically,” velocity in fluid conductors should be flowing adequately to have the system running smoothly and efficiently. Chart 3 below shows what the velocity of the process fluid should be in various lines.

3. What is the working system pressure? Consider selection based on the question, “Can this filter handle the pressure it will experience?” If a filter collapses in use, not only will it lose its integrity and break down, but it will cause the system to become damaged or break down. When a filter collapses, fragments of epoxy or filter media will get into the flow stream and cause damage to downstream equipment.

4. What is the fluid? Is it standard hydraulic fluid? Is it a petroleum-based product where fluid and equipment will work in harmony? It is extremely important to have all system components, not only filters, compatible with the fluid. Otherwise, you are asking for serious system damage or destruction. Damage could be caused to equipment and seals, creating leaks, and allowing serious contamination problems to occur.

5. What is the viscosity of the fluid? The viscosity of standard hydraulic fluid is 150-200 SUS, simply stated. However, what if there was a process fluid in the system of 250-300 SUS? System designers should recommend the proper fluid for the application. A fluid with higher viscosity is thicker than standard hydraulic fluid. This must be taken into consideration because the fluid that has a higher viscosity will create a higher-pressure drop flowing through the system, especially during cold weather start-ups. When passing through filters it is necessary to have them strong enough to be able to handle higher pressure drops or filter collapse and destruction may occur.

6. What type of pump is being used? Is it a piston, gear, vane, or other type of pump? This would be important when installing a new or replacement suction strainer. Different pumps sometimes require more critical protection. If the pump fails, the system fails. Suction strainers protect the pump.

7. What type of filter is required? In-tank or in-line, when referring to suction straining? Do you need a replacement filter for an existing housing only? Or a replacement filter with a replacement cartridge in the housing? It is important to visually get this in your mind if you are unsure of what the requirement may be. Is filter media wire cloth, cellulose or a synthetic? If so, what is the synthetic material and has it been performing properly?

8. Will the system be operating continuously, intermittently, or infrequently? If a system is in operation continuously, selection may be one that can withstand the rigors of the constant operation. Is it a filter made with wire cloth media instead of cellulose or micro-glass media? If the filter is used in a system that only operates occasionally, a less costly one may be installed. The important decision is to install a filter that is best for the operation. The worst possible occurrence is a machine breaking down because the filter installed couldn’t withstand the operation.

9. What is the system operating temperature? Hydraulic system standard operating temperature is “usually” around 100°F. If the temperature runs hotter than standard, it must be kept in check. Too hot a system can destroy seals and cause leakage, as well as breakdown of the fluid. Either a fluid cooler should be installed or the proper seals, for example, Buna, Teflon, Viton, etc, must be used to be compatible with the operation.

10. Is the system indoors or outdoors? Moisture is the second most damaging contaminant in any system. An outside environment will most likely allow moisture into the system. Hygroscopic breathers may be necessary to prevent moisture from entering the system. Even in some indoor systems, depending on the geographical region, moisture can play havoc with a system, too. It may be necessary to use stainless steel filters with housings to prevent corrosion from occurring. If you are not sure if the metal “details” of a filter require stainless steel or plated steel, ask yourself the question, “What are the other components in the system made of?” Therein may answer your question of which type of filter to use.

11. What about the air that gets into the reservoir? The tank breather is one area which seems to be neglected and not serviced as often as it should be. As fluid levels rise and fall in the reservoir, air enters and is expelled from the reservoir. It carries both particles and moisture contaminants. A hygroscopic breather may be warranted. Sizing of this component is as critical as any other system filter. Air intake is measured in cubic feet per minute (CFM or SCFM). Sizing is important but it is permissible to oversize your air filter. A “general” rule of thumb to follow when sizing a tank breather is to use the following formula: Gallons per Minute, divided by 7.5 = CFM (GPM/7.5 = CFM).

12. What mesh or micron should be used? To completely size a filter, the level of filtration is critical. This could make or break an efficient operation. Suction lines should be no finer than 200 mesh (74 micron). Having too fine of filtration on the suction side may cause pump cavitation. Follow a few general rules above in the chart in Item #6. Protecting the pump in an effective manner is critical. “Typically,” the pressure line has the finest filtration in the system. It could be as fine as being in the sub-micron area depending on the application. The return line should be anywhere from 74 microns to 5 microns, depending on the application. This is an area that should be looked at closely because there are so many different applications with so many different requirements and with so many various scenarios. Know your equipment.

These are points to consider when sizing a filter to a system to keep it running in a smooth and efficient manner. To protect the entire system, you want adequate filtration in all lines; suction, pressure, return, and tank breather. To reduce the downtown of your system, reduce the contamination in it.

The first step in reducing downtime is to size filters correctly, along with a properly scheduled maintenance program. Hydraulic equipment is a valuable and expensive capital investment, and the use cost is very high. Remember that to better reflect the economic benefits, make it a goal to strengthen the maintenance program to keep equipment operating as efficiently as possible.

In conclusion

Whether you are designing a new fluid power system or maintaining an existing one, your operation requires proper filtration to protect its critical parts. Selection of proper filtering components and establishing a regular maintenance program will ensure your system operates at peak efficiency with limited downtime. MFP’s Redmond says that all their hydraulic power units ship with a list of recommended spare parts including replacement filters. Sticking to the manufacturer’s recommendations is your best bet in maintaining your equipment. •