Pump or Venturi?

When a salesperson is quoting a vacuum installation, a common question to the end user is, “Would you prefer a vacuum pump or venturi?” More often than not, the end user will opt for a vacuum pump as he “doesn’t have enough compressed air.” This is a common statement, even if he does have enough compressed air, as that is one of the industry’s energy focus points, but is it the right choice from the offset? This article offers basic comparative information to enable the salesperson or design engineer to make a more informed decision regarding the pump or venturi options available.

A vacuum pump is a rotary or reciprocating mechanical vacuum-generating device. This is an important definition. A venturi manufacturer may refer to his product as a vacuum “pump.” This is inaccurate and very misleading. A vacuum venturi or ejector (the same device) is powered by compressed air. A vacuum PUMP is powered by an electric or indeed sometimes, but rarely, a hydraulic motor.

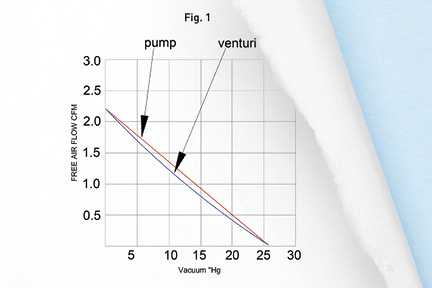

The vacuum-pump manufacturer will offer the most obvious advantage of his product over the venturi supplier – efficiency. Fig. 1 shows a flow curve of a pump and venturi that have similar performance. However, the compressed air used for the venturi requires a compressor power of about 0.9 hp, whereas the pump uses a motor of about 0.25 hp. It’s a convincing argument for using a pump. Case closed, right? Well, jumping to conclusions normally costs someone something.

What is this pump or venturi being used for? When choosing a vacuum pump or venturi, the application is key to the final decision. At least it should be, to get the best solution for the end user.

Here’s a typical vacuum-lifting application: a small end-of-arm tool consisting of eight small vacuum cups of Ø40 mm (Ø1.5″). These eight cups are picking up a flat plastic sheet, which is, of course, non porous. Cycle rate is one sheet pick every 15 seconds, or four sheets a minute. The piece is being held for only three seconds during transfer. What’s the most efficient? Pump or venturi?

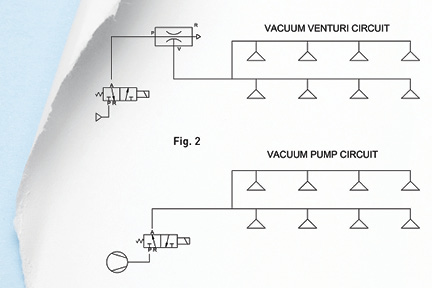

The pump will run continuously with the vacuum being turned on and off via a vacuum solenoid valve. The venturi will run only when required (during the lift part of the cycle), turned on and off using a compressed air solenoid valve. The vacuum pump uses 0.25 hp all day long during a 24-hour shift. The venturi uses 0.9 hp for every three seconds of a 15-second cycle. Therefore, the venturi uses on average 0.18 hp of compressed air over the same cycle period. Consequently, the venturi is “more efficient” in overall running costs. Both of these circuits are illustrated in Fig. 2.

However, let’s review an alternative application. The end user requires vacuum to hold down a piece of plastic sheet while it’s being machined on a CNC router. The pump is the better choice. Why? The pump and the venturi are always operating to hold the plastic sheet in place. Therefore, the pump uses less energy and consequently is the better choice, at least for energy consumption.

Now you could use an “energy-saving” circuit with the venturi. What this offers for the user, as the term suggests, is a reduction in the amount of compressed air used. This is achieved by turning the venturi off when it has achieved vacuum and only turning it on again when the vacuum level falls below a preset safe vacuum degree. This is ideal for use on a non-porous product, such as the plastic sheet application described previously, but probably not as useful when holding a porous product, such as cardboard or MDF sheet, in place.

Vacuum pumps are used in installations where compressed air is not available, and a venturi cannot be used because of that. It’s also easier for the machine builder to supply a “stand-alone” machine with an integral vacuum source. But the venturi has certain advantages over the vacuum pump:

- Normally a lower initial cost of procurement

- Lighter weight

- Smaller dimensions

- No heat generation

- Virtually maintenance-free

- Readily available from many suppliers

That all said, we have spoken so far about a small pump vs. a small venturi. In larger installations, a pump normally makes more sense—as long as the installation is correct. In a large lifting application where larger vacuum flows are required to either accommodate product leakage (cardboard box handling) or to supply many vacuum cups, a pump is normally the better choice for efficiency reasons and certainly a simpler installation. However, in larger applications, the pumps are large. Some weigh many hundreds of pounds. Therefore, the machine builder, even knowing the efficiency benefit, will often opt for vacuum venturi purely because they are easier to install. This is particularly true in end-of-arm robot tooling where automated tool changers are being utilized. It’s a lot easier to utilize an automatic tool changer with 5/16″ compressed air lines for venturi supply rather than 1″ diameter vacuum hose from the pump.

Of course as with most vacuum installations, what worked before will be used again. That is very common and is particularly true with vacuum applications. It may have not been the most efficient solution for the end user, but it worked. Retrofitting old vacuum systems is big business simply because of that. Vacuum technology hasn’t changed much over the years, but having a better understanding of how vacuum works and working with the end user to understand his concerns and needs offers the best solution to the industry rather than what simply does the job!

This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation.

About the Author: Daniel Pascoe is general manager of Vacuforce Inc, a manufacturer and distributor of vacuum components and systems for industry in North America. Daniel can be reached via the Vacuforce website at www.vacuforce.com or directly at dpascoe@vacuforce.com. Find Vacuforce on Facebook and keep updated on Twitter.

A car’s AC is simple to repair if it’s just low on freon.