Raising the bar: Accumulators–Energy Savers or Energy Wasters?

By Dan Helgerson

Do accumulators save energy or waste it? The answer is yes and yes. Let me explain.

I started my fluid power career with a distributor who serviced the mobile and marine markets. We had a limited product line and an even more limited knowledge of fluid power. In some of my earliest training, when the question of accumulators came up, I was told that it would be best to stay away from them. They were really complicated and would only be confusing. I was led to believe that accumulators were only used in special industrial applications, and so I did not need to be bothered with them. Seven years later, I found myself working for a company that was the U.S. distributor for a major line of accumulators. It seemed the cure for every problem was to throw an accumulator into the circuit. Somewhere between never and always was the right time to use an accumulator.

Accumulators can be used for pulsation dampening, surge suppression, energy storage, auxiliary power, and cushioning. In this column I’ll focus on gas accumulators used for auxiliary power to save energy.

Whenever there are large differences in flow requirements, such as when there is a substantial dwell time, in general it’s a good idea to consider an accumulator in the system. Consider an application in which we need 100 lpm at 17 MPa to drive a motor for 15 seconds, then wait 45 seconds before repeating the motion.

Power = lpm x MPa / 60 x Efficiency. PkW = 100 x 17 / 60 x 85% = 33 kW

We would need 33 kW to drive the system. However, the motor only operates for 15 seconds each minute. The average flow is 25 lpm. By using an accumulator, we could use a pump that produced a constant flow of 25 lpm. This could “flatten the curve” and allow the use of a smaller power source.

At first glance it might appear that we could use a 25-liter accumulator, and our power requirement would be 25 lpm x 17 MPa / 60 x 85%, which equals 8.33 kW, a savings of nearly 75%. If you think this sounds too good to be true, you are correct.

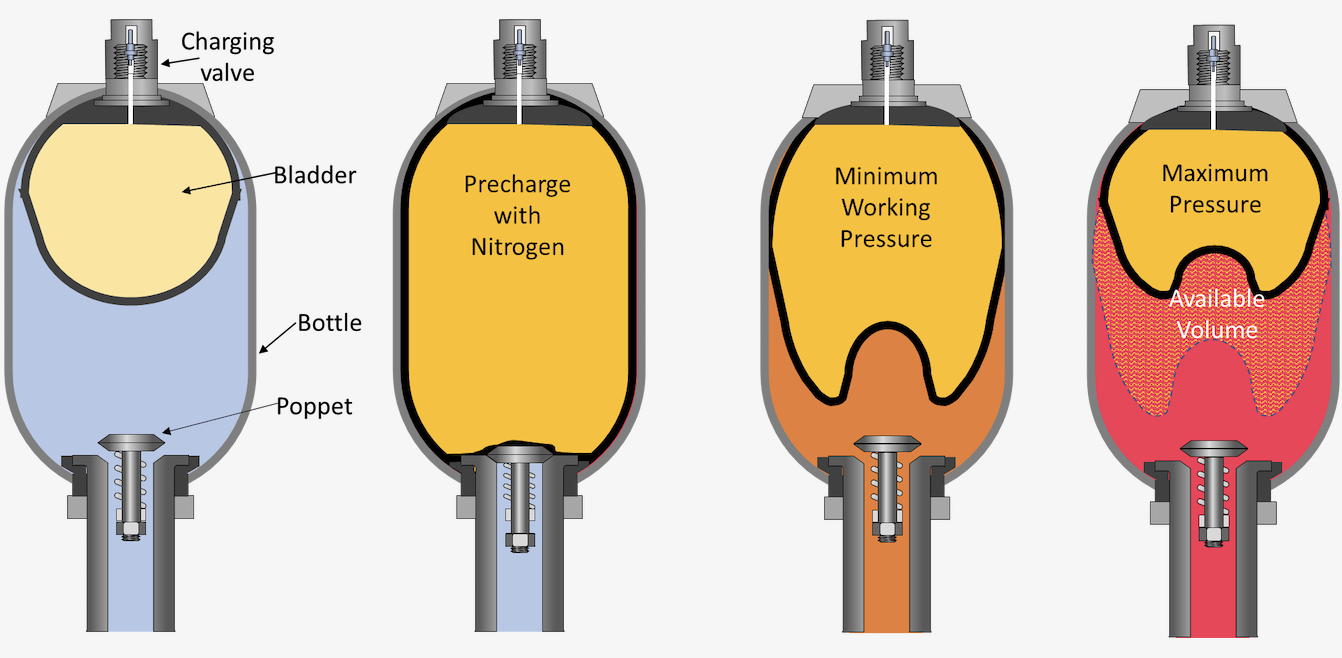

Gas accumulators are not characterized by the amount of liquid they can hold but by the space inside, referred to as the gas volume. The size is chosen using four criteria: required (available) volume, precharge gas pressure, minimum working pressure, and maximum pressure. The available volume is the difference in gas volume between the minimum and maximum pressures as shown in the illustration.

The hydraulic motor requires 17 MPa to operate. This determines the minimum working pressure. The precharge gas pressure can vary with the application, but I like to use 85% of the minimum operating pressure; in this case, about 15 MPa. What remains is the required available volume and the maximum pressure to determine the accumulator size.

A pump that would provide 25 lpm would supply 6.25 liters during the 15-second run time, leaving 18.75 liters needed from the accumulator. This is our required available volume.

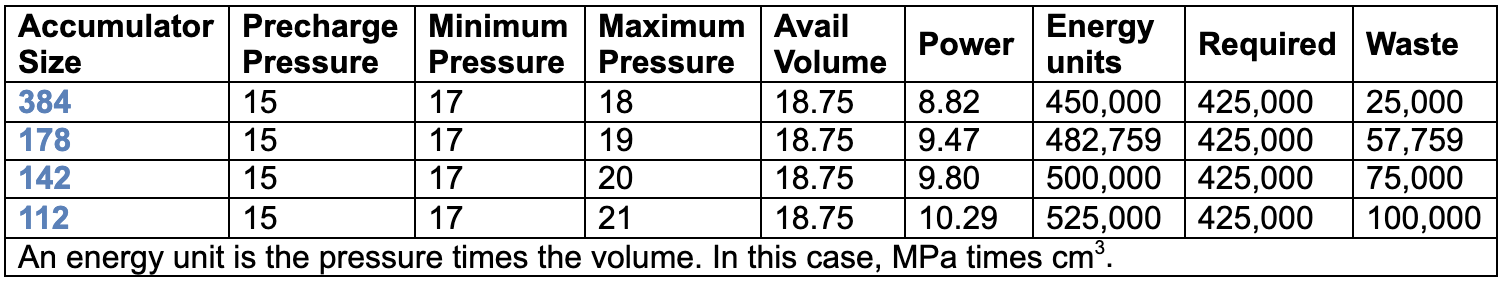

Looking at the sizing chart below, we can see that if we set our maximum pressure at 18 MPa, it would require an accumulator with a volume of at least 384 liters. An accumulator of only 112 liters would fit better on the machine but would require a maximum pressure of 21 MPa.

The large accumulator uses the least amount of power, but its size makes it impractical. The small accumulator costs less and takes up less space but requires about 14% more power.

This brings us to the original question: are accumulators energy savers or wasters? As you can see, accumulators are both.

Compared to not using an accumulator and needing 33 kW to drive the 100-lpm pump, the smaller pump supplying an accumulator requires only 10.29 kW, a savings of 69%. Yes, energy is saved. However, the amount of energy units needed to drive the hydraulic motor is 450,000 MPa/cm3, compared to the 525,000 MPa/cm3 used. This is a waste of 100,000 MPa/cm3. Therefore, energy is wasted.

Is there a more efficient solution? Hmmmmmm. . . .

Fluid Power Journal encourages conversation about issues addressed in “Raising the bar.” Please use the Comment function at the bottom of the page to take part in the discussion with author Dan Helgerson.

Related Posts

Breaking News: Voith Acquires ARGO-HYTOS

Calculating Intensifier Ratio for Given Pressure and Flow

Viva Las Vegas! IFPE Gambling on Record Attendance

Test Your Skills: Ensure Component Compatibility

Six Considerations When Selecting a Ball Valve

4 Ridiculous Ways Manufacturing Is Portrayed in the Media

Get Our Enews!

Sign up for the FPJ Insider Guide

Sign up to receive fluid power industry news, economic updates, professional development content, and product news delivered right to your inbox.

We will never share your data with a third party without your permission. Adjust your email preferences at any time, and unsubscribing is quick and easy.

Fluid Power Journal Resources