Research to Watch: Controlled Stirling Power Unit

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Presented By: Seth Thomas, a student at Vanderbilt University.

Project Leader: Eric Barth, Professor of Mechanical Engineering

Institution: Vanderbilt University

PURPOSE

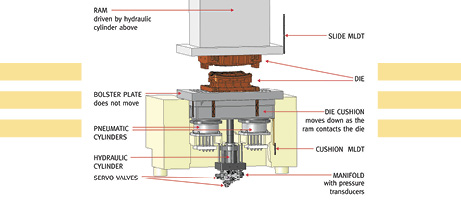

As the scope of the market for mobile robots and exoskeletons broadens, the need for longer-lasting, lighter-weight power sources to facilitate autonomous operation of these devices increases. To address this need, this project is developing a completely silent, high energy density, efficient and portable fluid-power supply using a Controlled Stirling Power Unit. The Stirling device can use a number of highly energy-dense, flexible fuels for available heat sources, such as butane, methane, natural gas, propane or any form of waste heat to create hydraulic or pneumatic fluid power in an easily scalable design.

PROGRESS

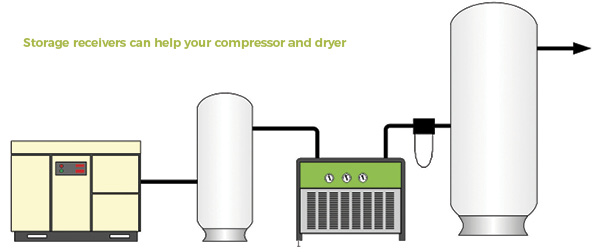

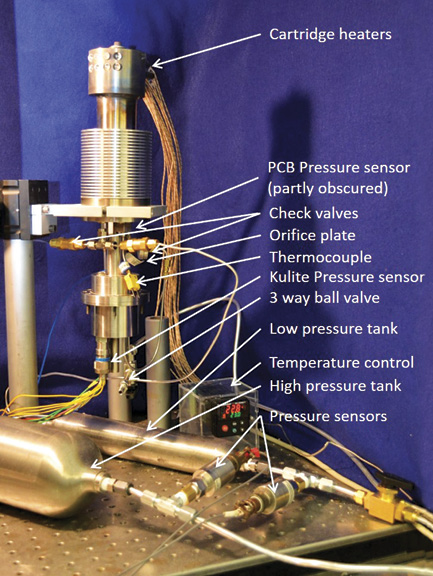

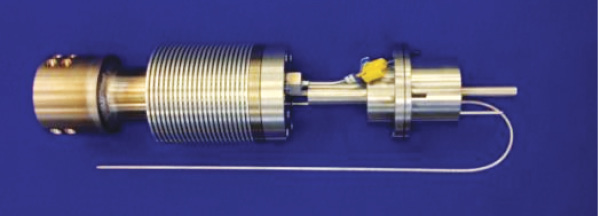

A controlled Stirling power unit has been developed to serve as a compact, portable, fluid-powered actuation system. The hydrocarbon fuel drives a power extraction unit by converting the absorbed heat to oscillatory pressure energy. Additionally, the controlled Stirling power unit is silent (whisper level dBA). The testing and development of prototypes continue. Experiments measured heater head temperature, average engine pressure and displacer frequency, and compared the use of helium and air. The unit is now in its 2nd generation prototype. The changes in this generation include using air instead of helium as the working fluid (helium is difficult to seal, whereas air is more practical), moving from a linear motor to a drive-shaft setup in order to increase the frequency of the oscillating displacer piston, and using a multi-stage model instead of a single-stage model since the multi-stage is a better design for air and the higher frequency oscillations.

NEXT STEPS

For the 2nd generation prototype, the model predictions for the multi-stage unit will be experimentally verified; the model will continue to be refined, and a back-of-the-envelope performance equation akin to the Beale equation (which characterizes the performance of Stirling engines) will be produced. The power output and efficiency of a series and parallel multi-stage thermocompressor will be compared with those of off-the-shelf compressors. For the 3rd generation prototype, partnerships will be secured, and an additively-manufactured prototype will be designed for production at a national lab for incorporation into an exhaust gas manifold.