Revolutionizing road safety: Improving the tire curing process

By Mindy Schoeff, Marketing Communications Manager, Proportion Air.

In today’s fast paced and competitive automotive industry, the quality and performance of tires is paramount. Tire manufacturers know the significance of staying ahead of the curve and offering quality products. One major consideration in providing quality products is accurate, repeatable regulation of pneumatic pressure throughout the manufacturing process. Manufacturers who understand how the compressed air and gases, including steam, are best used in their facilities can save time, money and other resources by choosing the right pneumatic device for their applications.

Tire Curing

Steam tire curing is one method used to cure or vulcanize tires ensuring they are durable and long-lasting. Curing requires tires to be placed into a mold and heated to more than 300 degrees F for around 15 minutes. Ensuring the correct temperature is reached and maintained during the process is critical for a safe, high-quality product.

Using an air-piloted steam control valve to throttle or modulate the flow of steam is a traditional method for achieving the correct temperature for tire curing. Steam is supplied at a specific pressure. For saturated steam, the relationship between pressure and temperature is direct: Controlling pressure is controlling temperature. However, process valves are made to control flow. Using a valve in this application requires programming a PID loop. The PID can introduce latency in the response. Process valve performance time for reaching and maintaining the correct steam temperature for tire curing can take around 45 minutes with this setup.

A regulator is a faster, more efficient way to achieve steam temperature. Taking advantage of pressure/temperature relationship of saturated steam saves time, because the dithering that happens when a control valve PID loop is trying to find the setpoint is removed. Using this method, temperature is achieved in about 10 minutes rather than 45. In addition to the time savings, a steam regulator is often easier to use and repair.

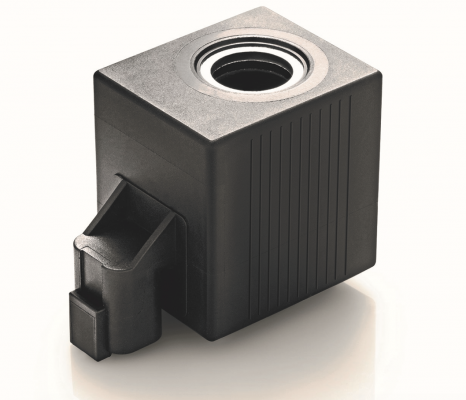

To achieve this kind of control, a Proportion-Air QB1X electronic pressure regulator piloting a BD-Series dome-loaded regulator allows for stable pressure control of steam for tire curing. For higher accuracy and tighter pressure control, a QB2X dual-loop regulator and a DSTY pressure transducer can be used.

Pneumatic Control for Other Tire Manufacturing Processes

The need for accurate pneumatic control isn’t limited to curing. The process of manufacturing tires is complicated and consists of numerous components that must be compiled and cured under intense heat and/or specific pressures. Other tire manufacturing applications include:

- Tire balancing

- Tire uniformity testing

- Tire retreading

- Tire building

- Sidewall stitching

- Tire inflation

Proportion-Air offers closed loop electronic flow control and pressure control regulators for a variety of applications in the development and use of rubber tire materials.

For more information on Proportion-Air and the company’s accurate, repeatable, and customizable proportional pneumatic pressure and flow control products, visit proportionair.com or call 888-200-9564.