Rotational Speed Sensors for Hydraulic Drive Units

If you are a manufacturer who equips hydraulic units with rotational speed measurement devices, or if you’re a user who buys such units from a supplier, the question is almost always the same: Does the standard integrated solution for measuring rotational speed fit? All too frequently, the answer is no. Or, if you’re a hydraulic supplier, the question could be: Does your standard-use rotational speed measurement device precisely fit your customer’s demands? Again, the answer is often no.

Custom solutions, while well-functioning, offer disadvantages such as project-related, unplanned development expenditure; no amortization with larger number of items; additional testing and qualification expenditure; additional documentation expenditure; defect potential while upgrading the system; and defect potential when servicing in the field.

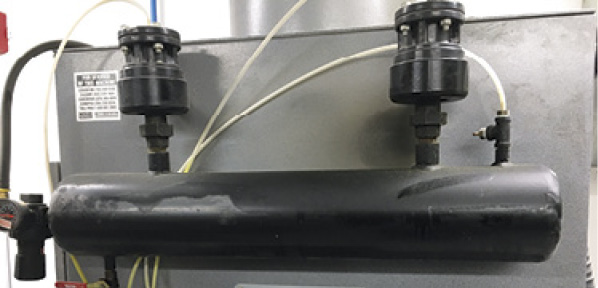

The engineers at RHEINTACHO in Germany frequently experienced the above scenarios, so they developed the FE rotational speed sensors with three electronic versions—1-channel, 2-channel, and PWM signal output—the “three musketeers of the sensor world” with installation-compatible, highly compact housings.

The range also offers two different immersion depths (18.4 mm and 32 mm) and a variety of different cable lengths and types of plugs (on the cable). All sensors are built to protection classes IP6K9K and IP67.

The 1-channel version is suitable if the needs are limited to the measurement of rotational speed. Carefully selected components guarantee highly tolerant contact behavior with respect to all types of target geometries and air gaps. The output signal is a square wave, the amplitude of which is independent of the rotational speed. In this way, stable signals are achieved, even with slow rotational speeds.

With its two-phase shifted square wave signals, the 2-channel version offers the same advantages as mentioned above. However, with its two offset signals, you have the additional possibility of identifying the direction of rotation.

In contrast to the two variants described above (voltage signal), the 2-channel construction with pulse-width modulated signal (PWM) works using a current signal with information regarding the rotational direction transmitted via the varying length of the pulses. In this way, this sensor also produces a signal with constant amplitude, independent of the rotational speed. This sensor has the ability to identify the rotational direction and also can carry out other diagnostic functions such as the identification of idle status, a critical air gap, and critical installation position.

The mechanical interfaces of this sensor product range are identical, regardless of which signal you or your users select. You choose the appropriate rotational speed sensor based on your application’s specific requirements.

For more information: RHEINTACHO Messtechnik GmbH specializes in the field of rotational speed. Based in Freiburg, the company has over 70 employees. Its subsidiary, RHEINTACHO UK, Ltd., specializes in the production of non-electronic measurement and indication instruments, and acts as a sales and service center for the UK and Ireland. Visit www.rheintacho.com.