Selecting Hydraulic Solenoid Valves

By Jordan McDowell, Content Strategist, G&G Hydraulics Corporation—

Hydraulic solenoid valves are popular in industrial and commercial applications. These electrically controlled valves are used in hydraulic systems to open, close, or change the direction of the flow of fluids, ensuring that the system runs at peak efficiency.

The valves are used in a wide range of applications, including:

- Process control in manufacturing plants

- Turbine systems

- Water supply systems

- Wastewater treatment plants

- Fuel supply systems

- Hydraulic machinery in the aerospace industry

- Hydraulic pumps, motors, and brakes in the automotive industry

- Heavy machinery in construction

Choosing the right solenoid valve for an application is essential to ensure that the system performs as intended and that it can handle any unexpected challenges along the way. In this article, we’ll look at criteria for selecting the best hydraulic solenoid valve for your needs.

Number of ports and positions

The suitable number of ports and positions in a solenoid valve is based on the application’s overall requirements. The more ports you have, the greater your selection flexibility. This is because solenoid valves come in manifolds that can support multiple positions with one valve or a single position per valve (lift type). If you need less than five positions and three ports, there’s no reason to select an electromagnetic solution over pneumatic.

On the other hand, if you have more than five positions and three ports, or a mix of single-position valves with manifolds that support multiple positions in one valve (lift type), then an electromagnetic solution is required. It is important to remember that not all solenoid valves are available for lift types, while most pneumatic flow control valves are lift types, which means you will have less selection flexibility.

Additionally, if the valves need to handle high pressures or flows, then an electromagnetic solution is necessary. Pneumatic valves cannot be used for those applications due to their inherent limitations on higher pressures and flows. Understanding the number of ports and positions you need is the first step in selecting an appropriate solenoid valve type for your hydraulic application.

Flow requirements

The flow requirements for a hydraulic application play a significant role in determining the size of the solenoid valve. The flow rate must be considered in conjunction with the pressure drop across the valve, especially in applications like commercial hydroponics, where a constant flow requirement is needed. Generally speaking, the higher the solenoid coil current, the greater the energy consumption and heat generation. If you’re using a DC power supply that’s not regulated by a PWM controller, this can result in heating the coils and eventually damaging them.

Depending on your application’s flow requirements, choose a solenoid valve with an appropriately sized orifice (nozzle). The nozzle size affects the pressure drop across the orifices at varying pressures and flows. In some cases, flow requirements may be too low to warrant using a solenoid valve at all. When choosing the appropriate orifice size for your application, consider how it will affect energy consumption and operational costs as well as meeting performance expectations.

Flow requirements vary greatly depending on the application, so consult a hydraulic solenoid valve expert for assistance with flow calculations and to determine the appropriate orifice size. When choosing a pressure drop, you should consider the trade-off between increased energy consumption and heat generation on one hand, and achieving adequate performance based on the application’s parameters, including process-fluid viscosity, on the other hand.

Spool action

Determine the solenoid valve’s spool action based on whether your hydraulic application requires the spool to stay in place when de-energized or return to the center. For spool action valves, the center position is typically not a rest state. That means it takes more energy to move the spool back into the resting/intermediate position after being in an energized or de-energized state. In short, if you need your solenoid valve to stay in a rest state when de-energized, you’ll need to take this into account.

The type of solenoid valve you choose matters. For example, spool action valves typically have faster response rates than paddle-style valves. But that doesn’t mean they are better suited for every hydraulic application. It’s crucial to consider all the features, benefits, and requirements to determine which spool action solenoid valves are right for your application. The flow direction and speed required for optimal performance determines which spool action valve is best.

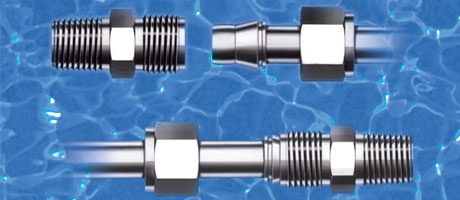

The valve’s material

The solenoid valve’s materials must be compatible with the properties of the application’s flowing media. For example, the valve body must be strong enough to handle high pressure and temperature. At the same time, it shouldn’t corrode due to interaction with corrosive chemicals such as chlorine or sulfuric acid in the flowing media. Different types of materials are used for the valve body, which is why it’s important to understand your material options.

The most common materials used for solenoid valves are:

- Cast iron (body)

- Aluminum (bodies and internals)

- Carbon steel (internals only in some cases). Valves made with these bodies work best when the media is corrosive.

- Stainless steel (bodies, internals, and trim). Valves made with these bodies have a longer life span because they’re resistant to corrosion.

If the flowing media contains sulfuric acid or chlorine chemicals, consider valves made of stainless steel. Brass is a more expensive option than cast iron or aluminum, but it has excellent properties for solenoid applications in high-temperature areas. If the flowing media contains oxygen, nitrogen, or carbon dioxide gases, select valves made of aluminum or brass because the solenoid coils have a high chance to oxidize.

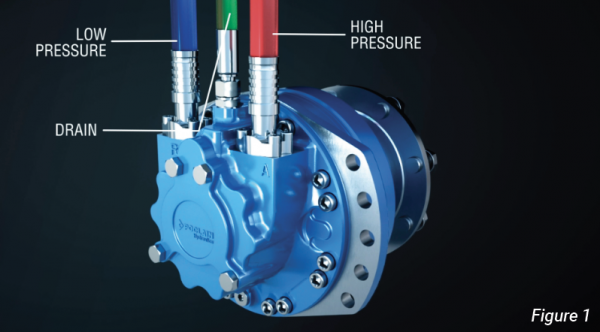

Pressure requirements

The solenoid valves you choose should be able to withstand the maximum pressure required for your hydraulic applications. If the valves cannot handle high pressure, they can fail or become a safety hazard. Pressure is a serious consideration, and it should be covered in your engineering specs. This is especially important when dealing with hydraulic applications for lifting or other heavy-duty purposes. The valves should also have a metal-to-metal seat, which can prevent leaks under pressure.

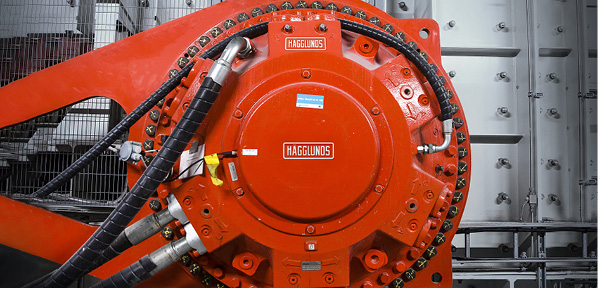

For low-flow and nonshock applications, standard elastomer seats work well. Select a valve that is rated for the highest pressure you expect to see. The valves should be able to handle the maximum anticipated flow levels without excessive leakage. If the system has multiple stages, each stage needs its own solenoid valve and coil assembly to maintain equal pressures on both sides of the piston inside each cylinder. This is especially important for multicylinder hydraulic systems, which are typically used in heavy machinery.

Currently, it’s not possible to use a single coil assembly and solenoid valve to control the movement of multiple pistons inside individual cylinders because each piston has its own pressure zone based on fluid volume. You must purchase one coil assembly and solenoid valve for each piston. Keep in mind that the maximum operating pressure in hydraulic applications can vary widely. Be sure you select a solenoid valve that can handle the maximum pressure you expect in your system while maintaining sufficient flow capacity for the safe operation of all necessary components within each cylinder.

Temperature requirements

The final selection criteria concern ensuring that your hydraulic solenoid valves and their materials can withstand the minimum and maximum temperature requirements of the applications. Temperature is essential in determining solenoid valve capacity; it affects the fluid’s flow and viscosity. If the temperature is too low, you might experience a slow response time, or fluid may not flow at all. At higher temperatures, your solenoid valve could be damaged by the heat generated from its coil, and the higher temperature could affect the fluid’s viscosity.

Temperature is critical if you’re using hydraulic solenoid valves for steam applications. Many materials used in their construction cannot withstand temperatures above 200°F (93°C). If your application requires high operating pressure but doesn’t allow for a temperature adjustment, it may be necessary to use a solenoid valve with the required temperature rating. If your application may require working at high temperatures, select a hydraulic solenoid valve that can withstand these conditions without breaking down or experiencing reduced performance.

When selecting hydraulic solenoid valves, it’s important to have a thorough understanding of the factors that affect their performance. It’s also valuable to research users’ experiences with different brands and models. This can be an indicator of how well suited a valve is to particular applications. Depending on your application, solenoid valves can be a great choice for controlling flow in a hydraulic system and should work well with most other components.

Jordan, this was a fascinating read! In hydraulic systems, the solenoid valves direct the flow of hydraulic fluid inside the cylinder, which regulates the piston’s motion. Hydraulic solenoid valves are utilized in many different applications, such as wood chippers, stump grinders, bucket trucks, and automobile crushers. They’re also used in car gearboxes, snowplows, backhoes, road pavers, steamrollers, excavators, and cranes, among other things.