Six Considerations When Selecting a Ball Valve

By Nick Spanhak. Nick Spanhak is product sales manager, Parker Fluid System Connectors Division. In this role, he handles a broad product portfolio, including ball valves.

Ball valves are a versatile and essential component in a fluid conveyance system. They allow for a line to be completely shut off from the flow of a fluid so maintenance can easily be performed. Due to the reliable, tight seal created by the rotary ball, ball valves are the ideal valve of choice for liquid and gas conveyance lines. By selecting the right body material and seals, ball valves can be used in a multitude of applications, ranging from diesel fuel to compressed air.

It is important to note that ball valves can only be used in the fully on or fully off position. Ball valves are not designed to throttle the flow of a fluid. Using a ball valve in this application will result in premature failure of components and cause the system to leak or render it unable to be isolated.

When selecting a ball valve for your application, it is important to consider these six factors:

1| Body material

Common materials used for ball valve bodies include brass, carbon steel, stainless steel, and thermoplastic. Each material has its own advantages and disadvantages. Your application will determine what material you should select.

Brass

Brass ball valves are the most common option for general purpose applications. The chemical makeup of brass makes it a very strong and durable metal. If stored and used properly, brass ball valves are resistant to corrosion. They are also the most economical choice of materials. These valves are ideal for compressed air, diesel fuel, vacuum, and inert gas applications. Brass can be used for applications ranging up to 4 MPa (600 psi) (dependent on fluid) and 175° C (350° F). For applications such as biodiesel, there is also an electroless nickel plated option for greater chemical compatibility.

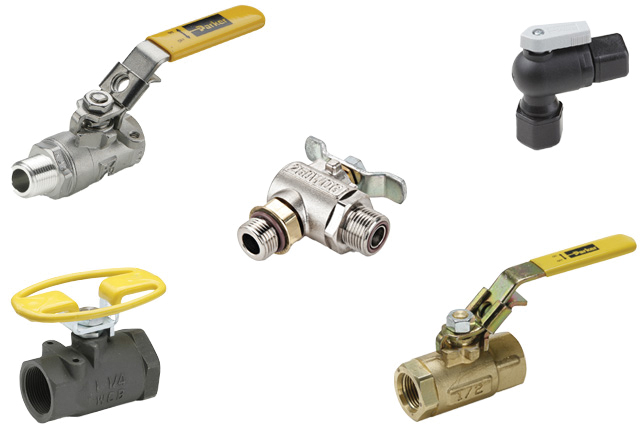

Ball valves, like these from Parker, are available in different materials and shapes and are a versatile component to allow isolation of a fluid conveyance line.

(Photo courtesy of Parker)

Carbon steel

Carbon steel ball valves are commonly used for hydraulic systems where pressure ratings can exceed 21 MPa (3,000 psi). High-quality carbon steel ball valves can handle pressure ratings of up to 41 MPa (6,000 psi), depending on size. The downsides of carbon steel are the chemical compatibility and temperature rating. When selecting a carbon steel valve, the type of fluid needs to be confirmed so that it will not cause a negative reaction with the valve. While still respectable, a carbon steel valve can only handle temperatures of around 99° C (210° F). The temperature of the application needs to be monitored to ensure the valve will perform as expected.

Stainless steel

Stainless steel ball valves are the most durable option. These valves offer the most robust offering of compatible chemicals. The chemical makeup of stainless steel offers natural corrosion resistance. These valves are also towards the top for pressure and temperature ratings. Many stainless steel ball valves can handle pressures of 14 MPa (2,000 psi) and temperatures of 204° C (400° F). The downside of these valves is the cost. Stainless steel valves are among the most expensive available options. Due to the cost, you will see these valves used sparingly, mostly in food/beverage washdown applications.

Thermoplastic

Thermoplastic ball valves are the ideal option for applications that require high purity. These valves are commonly used in drinking water and beverage dispensing applications. In addition to beverages, these valves can be used for a select list of chemicals, such as liquid fertilizer. (dependent on the type of thermoplastic used) The all-plastic construction makes these valves naturally corrosion resistant. Thermoplastic valves have lower pressure and temperature ratings. These valves are rated for applications with a pressure rating of 1 MPa (150 psi) and up to 65° C (150° F).

Due to their malleability, brass body ball valves (like these from Parker) are available in the widest range of shapes and configurations.

(Photo courtesy of Parker)

2| Configuration

Selecting the correct valve configuration ensures proper hose, tube and pipe routing for optimal flow in your application. In addition to the standard in-line ball valve, some manufacturers, like Parker, also offer special configurations. Understanding where the ball valve is going to be used in your application determines what configuration you will need. Some of the more common shapes include:

- 3-way diversion

- 4-way diversion

- 90 elbow

- In-line

- Mini In-line

- Stacked in-line

3| Port connection

To determine the required port connection, it is best to investigate your application and understand if the valve will connect to a hose, tube, or directly into a piece of machinery or component. Some of the more common connection types (depending on body material) include:

- BSPP female/male threads

- Beaded hose barb

- NPT female/male threads

- O-ring face seal

- Push-to-connect

- Solder end

- Straight thread o-ring

- VDA

4| Seals

For a ball valve to provide a leak-free connection, a seal is required. The type of seal is dependent on the type of fluid being conveyed through the ball valve. Most valves have standard options for seals, but these can be customized to fit your application. Standard options include:

- Acetal

- EPDM

- FKM

- Fluorocarbon

- Nitrile

Parker’s ball valves are available with a wide range of handle options. The handle style does not change performance but is a matter of personal preference.

(Photo courtesy of Parker)

5| Handle

Even the handle can be customized on most ball valves. The choice of handle is dictated by two factors–the space available to turn the handle and personal preference. Common handle options include:

- Lever

- Oval

- Short lever handle

- Tee

- Pad locking handle

6| Venting

The last consideration when selecting a ball valve is whether or not the valve needs to be vented. There are both vented and non-vented options on most standard ball valves. When selecting a vented option, it is important to understand your application. Typically, vented ball valves should only be used on compressed air systems to allow venting of downstream pressure in a closed position. Using a vented ball valve on a fuel or oil line could result in costly leaks. It is important to note that a vented ball valve does not take the place of an OSHA-approved emergency shut-off.

If, after researching your options, you are unable to find a standard ball valve that fits your requirements, check to see if your supplier has the capabilities to custom design and manufacture one for you. Choosing a ball valve that exactly meets your application needs will go a long ways in providing you with a safe and efficient fluid conveyance system.