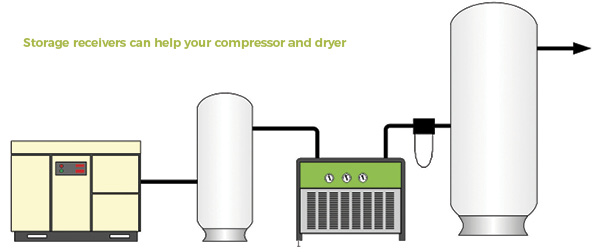

Storage Receivers: Wet or Dry?

By Ron Marshall for the Compressed Air Challenge

A common question asked when compressed air systems are being installed is where to locate the storage receiver. Should you put it right at the discharge of the air compressor, or should it be after the air dryer and main filters? Each location has its good and bad points. Installing the receiver right at the discharge of the compressor allows the compressed air a quiet zone of low velocity to cool down and drop out any entrained moisture. This helps make the air dryer more effective. Having the receiver right at the discharge of the compressor means the compressor can “see” the whole capacity of the receiver, and that’s a good thing. This makes the receiver more effective in reducing the compressor cycling frequency, making it run more efficiently if it is a lubricated screw compressor.

But, using wet storage is not without problems. Often the air dryer is sized at or near the rated capacity of the air compressor. If the compressed air flow has any peak demands that exceed the capacity of the compressor, then some air will also come from the storage receiver to help the compressor. If this happens, all the air from a fully loaded compressor AND some of the air stored in the receiver will flow through the air dryer and filter. Since the stored air is wet, this additional flow could overload the air dryer and allow moisture to pass into the plant.

Placing the storage receiver on the dry side of the system solves this problem. The air stored in the receiver is already dried and will not overload the air dryer, but because the compressor must “look” through the pressure differentials of the dryer and filter, the receiver capacitance is less effective in reducing the compressor load/unload cycles.

For example, if the compressor is set at a 10-psi load/unload pressure band, the dryer pressure differential is 4 psi, and the filter pressure differential is 2 psi, the effective working pressure band for the compressor in relation to the dry receiver is only 4 psi (10 psi band minus the dryer and filter differential). This makes the tank only 4/10ths as effective as a tank installed at the compressor discharge.

Compressed Air Challenge training recommends putting storage receiver capacity in both locations, wet and dry. A typical size ratio would be 1/3rd of the storage as wet receiver and 2/3rds as dry. The total capacity of the receivers should be between 5 and 10 gallons per cfm of compressor capacity. With this best practice, the benefits of both locations can help to improve system operation and efficiency. Should you want to ensure that the dry tank is as effective as possible and the plant pressure is without sag due to the dryer and filter pressure differential, then you can ask your supplier to install remote sensing on the compressor so it can “see” past the dryer and filter (this should be done carefully so as not to overpressure the compressor).

Having both wet and dry receivers has an additional benefit in systems running in load/unload mode. Without a wet tank, the air dryer and filters see a step load changing from zero to 100% flow every time the compressor loads and unloads. If wet receiver capacity is installed, then the flow of air in the dryer and filter is smoother; when the compressor is unloaded, there is some flow coming from the receiver, which slows the step changes. This benefits the operation of the dryer.

Learn more about storage receivers at one of the Compressed Air Challenge seminars. For a schedule of events see www.compressedairchallenge.org.

Does anyone know about where I can find more about this topic? This just came up this week and there isn’t much on a Google search.