Compressed Air Efficiency: 5 Uses of Storage

Compressed air storage is an important part of any compressed air system. Air receivers help ensure better air quality, can lower your air compressor power consumption, and can help keep the system pressure constant. The installation of properly sized storage tanks can help your compressed air-powered machines work better, making plant production operations more reliable. Five valuable uses of compressed air storage are discussed in this article.

Cooling and Water Separation

The air produced by air compressors is often hot and completely saturated with water. This air and water mixture can overwhelm your air dryers, allowing wet air to contaminate downstream components. First passing the flow through a storage receiver allows the air to cool and the entrained water to separate out within the low-velocity “quiet zone” of the vessel. As a rule of thumb, every 20°F of cooling drops the water content in half. The water that condenses and falls to the bottom of the tank can then be removed by automatic drains.

Stabilizing Pressure

The larger the system storage capacity, the more stable the system pressure during periods of high demand. Consider a system with only 120 gallons of storage. A compressed air demand that exceeds the capacity of the installed compressor by 30 cfm will pull the system pressure down by 27 psi in one minute. If the storage receiver were five times bigger, the pressure would only drop by about 5 psi for the same flow event. Having a more stable pressure allows the system pressure to be set lower because you don’t need to compensate for low-pressure events, saving about 1% compressor power for every 2-psi pressure reduction.

Compressor Control

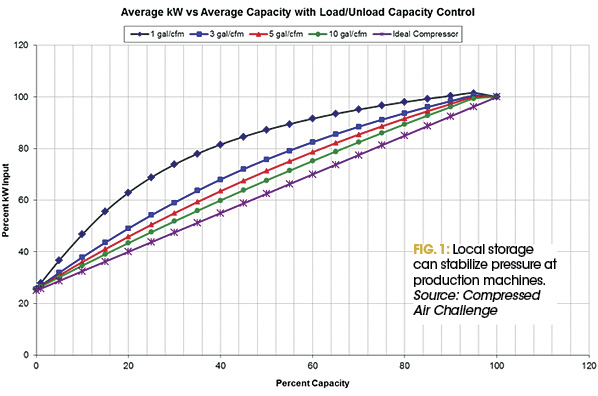

Large system storage can make the compressors run more efficiently. If you have lubricated screw compressors running in load/unload mode, the addition of storage capacity reduces the number of times per minute the compressor will cycle. Each time the compressor cycles, it must release air in its oil separator only to charge it back up when it reloads—not an efficient operation. A 30-hp compressor rated at 120 cfm with a 120-gallon receiver will cycle inefficiently over 160 times per minute. Installing a 660-gallon tank or larger for this size of compressor will reduce the cycles to less than 30 per minute and reduce the power consumption by 10% or more (Fig. 1).

Protect Critical Uses

Sometimes individual compressed air use is particularly sensitive to pressure fluctuations. It could be something like a clamping application or perhaps a clutch for a drive mechanism. If the system pressure varies excessively, there may be problems with these applications because a constant, reliable pressure is needed. In these cases, a properly sized local storage receiver with a check valve can be installed to protect sensitive applications. The check valve traps pressure in the storage receiver for the exclusive use of the local application. This allows main system pressure to vary for short periods of time, but protects sensitive applications.

Reduce High-Volume Uses

Once in a while, a system will have a compressed air demand that uses a large volume of compressed air in a short period of time. This demand might hit the system and overwhelm the system compressors, causing low pressure that might negatively affect other pressure-sensitive compressed air loads. This almost always causes system pressures to be set much higher than needed, causing the compressors to consume more energy (Fig. 2).

System storage receiver capacity can be applied to average out the effect of large, high-volume system demands so the compressors can operate at normal pressure, not affecting sensitive loads. For example, if the previous 30-hp, 120-cfm system with 120 gallons was hit with a 30-second – 240-cfm compressed air demand every five minutes, a 120-cubic foot event, the system pressure might drop by 80 psi during each load cycle. If 660 gallons of compressed air storage were added for the exclusive use of the event, the pressure would only drop by about 20 psi at the large user. The compressed air could be replenished between cycles in 4.5 minutes at a flow of only 27 cfm through a needle valve so that the receiver is full of air just before the next event. If this were done, it is possible other compressed air users would not see any pressure decay during the large event.

Compressed air storage can benefit compressed air systems in many ways. It is a rare case indeed where there is too much compressed air storage capacity. Consider adding storage to your system for better efficiency to save operating costs and increase system reliability.

By Ron Marshall for the Compressed Air Challenge

Learn more about system storage at one of the Compressed Air Challenge seminars or download a fact sheet from the website library. For a schedule of events, see www.compressedairchallenge.org.