New Test Method Raises Performance Standard for Rod Wipers in Hydraulic Systems

Dirt ingression is a major cause of hydraulic system inefficiency, degradation, and failure. Although superior filtration systems exist and are used to limit exposure to contaminants, there are a number of locations in a typical hydraulic system that remain vulnerable. Breather ports, external couplers, and power shaft systems that drive hydraulic pumps, external motors, and cylinders are included among areas that may be compromised. This article describes a new, innovative test method developed by Hallite in cooperation with Milwaukee School of Engineering (MSOE) to assess the amount of dirt entering a simulated hydraulic system through the rod wiper located on the hydraulic cylinder. It will discuss why and how such a test method (or specification) for rod wipers was developed, as well as the test procedure and conclusion derived from putting four different wiper products to the test, setting a new standard for the future of testing rod wipers in hydraulic systems.

The Quest for Standardization

The International Organization for Standardization (ISO) ISO 4406 provides a standard for rating contamination in hydraulic fluids. The standard establishes criteria that codes the amount of contamination for particles that are >4, >6, and >14 microns in size. Manufacturers of filtration systems and products use these codes to identify the level of protection that is provided by their products. The manufacturers of hydraulic components (valves, cylinders, pumps, etc.) use these codes to establish operational limits of contamination. However, hydraulic cylinder manufacturers struggle to define operational limits and deploy repeatable methods to prevent contamination ingression with any level of confidence. This is due to the axial movement of the rod, which plunges contamination into the cylinder and consequently into the hydraulic system. The key component that minimizes this from happening is the rod wiper.

Prior to this project, the only standardized test to assess contaminant exclusion of rod wipers was SAE J1195. Though some of the elements of SAE J1195 were valid to replicate hydraulic cylinders, key components were missing that provided valid conditions to assess the effectiveness of a rod wiper.

Since most hydraulic systems utilize multiple hydraulic cylinders to support linear actuation functions in the equipment, the potential for dirt ingression into the system increases exponentially. This fact makes a standard test method for dirt ingression prevention very important.

Specification

MSOE utilized SAE J1195 as a baseline to begin development of a test procedure. This included the application of industry best practices compiled from the input and feedback of hydraulic cylinder manufacturers. After numerous trials and adjustments were conducted over an eight-month period to best simulate actual field conditions, a repeatable, verifiable test standard was established.

MSOE’s Fluid Power Institute™ built a test rig with the following rod wiper ingression test parameters:

- Test duration: 24,000 cycles (80,000 linear feet travel)

- Cycle rate: 0.25 Hz (10 to 10.5 inches per second)

- Stroke length: 40 inches total

- Test pressure: atmospheric

- Test temperature: 150°F +/-2°F

- Test oil: MIL-PRF-46170

- ISO 12103-1-A4 coarse test dust

Procedure

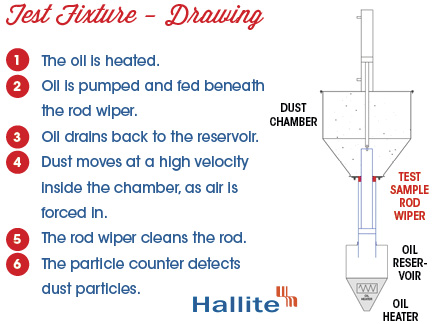

The test rod wiper was installed in the rod end of the cylinder housing along with a TPE-faced, two-piece rod seal (Hallite Type 16 profile) to simulate typical boundary lubrication that is found on the rod in standard cylinder applications. The hydraulic circulation fluid was heated to 150°F by heaters located in the reservoir, and the hydraulic fluid was circulated with the cylinder rod fully retracted (not cycling) until the temperature was achieved. The rod was then cycled through the dust chamber for the duration of 80,000 linear feet, and dirt content was measured in the oil reservoir via the particle counter (Fig. 1).

Test Results

MSOE tested the Hallite 520 and 820 wipers against two competitors. Based on these results, the 820 wipers provided the most protection, allowing the least amount of contamination into the test fixture. Note: the 820 wipers utilize a secondary protective structure outboard of the primary wiper lip (referred to as “Umbrella Wiper Technology”), which accounts for the better ingression protection.

The 520 wipers also provided a high level of protection against contamination when compared to similar competitor wipes. Review of the data shows the wipers (520 and 820) performed better during the entire test, allowing for less contaminant ingression than competitors. Both competitor wipers showed a higher degree of ingression as the test proceeded. Data suggests that the design and material combination for the wipers promotes best ingression protection with improved wear characteristics.

Conclusion

The hydraulic cylinder manufacturing industry now has a valid test procedure for rod wipers. Developed through Hallite’s cooperation with MSOE, this new test procedure enables the highest level of accurately assessing and measuring dry dirt ingression available. It is a major leap forward, establishing a repeatable pattern for the industry’s innovation of future test methods focused on wiper technologies used in a wide variety of real-world operating environments. And it demonstrates the value of continued commitment to understanding and developing technologies to improve the effectiveness of hydraulic seals and how they interact.

Test results are based on the conditions and methods as described in this article. Testing was completed by MSOE in cooperation with Hallite.

Can this test be done with water?

In many mobile application water getting into behind the wiper is a bigger problem than dust.