Wandfluh Launches New Modular Product Series

Targeted for mobile and marine equipment, new series manages higher flow and pressure applications.

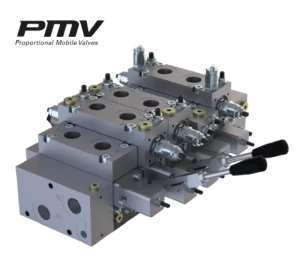

Wandfluh AG has launched a new product series under the name PMV – Proportional Mobile Valves in 2023. PMV is a flexible hydraulic concept that is modular in approach, allowing different size sections to be used in a single assembly but leaving each section individually adaptable to the function being controlled. The new product series is designed to efficiently manage higher flow and pressure applications. It is targeted for use on mobile and marine equipment where each function must be capable of providing fine operator control such as in the precision positioning of a crane winch or jib response to wind speed. These valves are currently being applied on cylinders and hydraulic motors used for heavy duty handling functions such as in construction machinery, loading cranes, winches, and machinery for agricultural and forestry.

PMV solutions are designed to be space-saving, compact hydraulic modules consisting of individual hydraulic valve sections, each configured to provide optimized force and speed control of a specific hydraulic actuator. The individual sections are self-contained, functional building blocks that can be ordered with an array of factory options. They are then fastened together with tie rods to make a single unit. Each section is adjusted to the specific application, making the modules very adaptable to specific machine requirements. Depending on the total flow rate required for the application, there can be up to 12 valve sections in one assembly.

Flexible and modular

During the development of the new PMV series, emphasis was placed on robustness, precision control, user options, flexibility, and modularity. This included having only a small number of different parts to create a multitude of variants within the assembled modules. This commonality makes it easier for the user to understand and become familiar with the product. It also lowers inventory and increases the availability of parts, making any field maintenance easier. As shown in figure 2, the two different size sections are assembled to optimize the flow control needed and save space. The ability to efficiently combine different size valve sections means functions that need fine control of only a few l/min (<1 gpm) can be combined with brute functions that need up to 700 l/min (185 gpm) in one PMV module without having to compromise machine operation or operator productivity.

This exceptional modularity also allows optimizations and adaptations to be made very easily in the field. Most valve sections can be exchanged on site without removing the complete unit from the machine, reducing downtime during maintenance, but also improving development and commissioning times when changes need to be made. Oscillation or vibrations can occur in complex hydraulic installations, so the PMV design allows for damping orifices to be inserted in various key places, all of which are accessible from the module’s external surfaces.

Sustainable and efficient

Worldwide demands for sustainable products are well known and increasing, so during development, special attention was paid to high power density. With the maximum continuously rated operating pressure of 42 MPa (6,000 psi) and optimized internal flow paths that provide the lowest possible pressure drop, there is minimal power loss through the module. This makes more power available at the actuator with reduced heat generation. The PMV also uses small, compact pilot valves with the lowest available electrical power consumption for proportional solenoid control. Pressure safety cut-off is accomplished by small, fast acting, direct operated relief valves. Low pressure drops (Δp), low actuation electrical power, optimized flows, compact dimensions, and ease of maintenance, prove that the PMV system is designed to meet the global demands for efficiency and sustainability.

Outstanding metering control by either electrical or manual operation can be further enhanced with the use of a load compensator that is available for each control section. With an adjustable compensator, the flow rate is set to within +/- one liter per minute and this flow accuracy is constant over the entire pressure range.

Features and expansion options

Various functions are easy to expand or already included in the standard module version. For more complex applications, an anti-saturation function can be mounted on the inlet plate so that all loads share the available flow. With this system, no actuator is starved for fluid. All actuators will slow proportionally but with minimal loss in productivity. If the load sense (LS) signal is too weak due to longer pump lines, it is possible to mount a small module with an LS amplifier on the inlet plate.

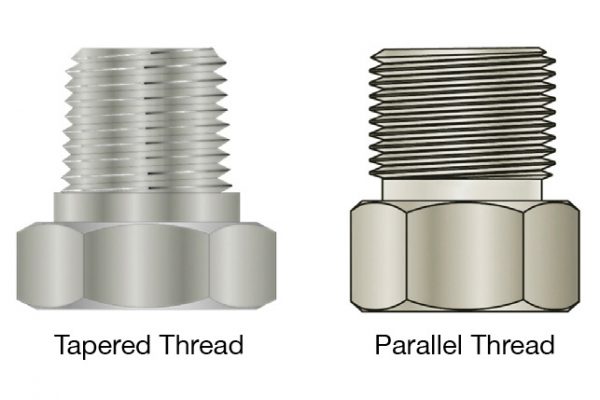

Modern mobile and marine equipment require the use of increased surface protection against corrosion. To meet this demand, the PMV Build Parts come with zinc/nickel coating as our standard protection, giving up to 1000 hours to red rust in the recognized ISO salt spray test.

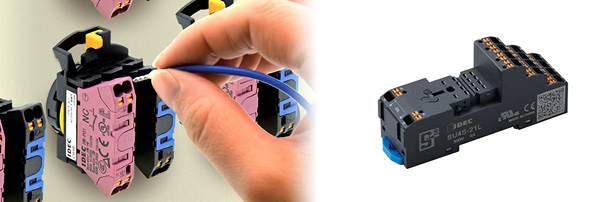

To compliment the manual handle control or for full remote or general electrical control, Wandfluh offers a range of amplifiers, controller formats, and control options in its standard product offering. When targeting mobile and marine applications, the MD2 module is recommended. This bulkhead mounted unit is fully sealed with shock & vibration certification and uses 2-part connectors for easy cable assemblies. Depending on the chosen model, it can drive up to 8 independently current-controlled proportional solenoids. It can also be interfaced with a wide variety of analogue command signals, including the common PWM signal. For digital control systems the MD2 has the option of CANopen, and SAE J1939 field bus integrated into these electronics. Other functions such as on-board electronics (OBE) and spool position control (LVDT) are already being developed and will soon be available as a standard solution for the PMV.

Wandfluh is proud to further expand its already extensive product range and offer the global market a well-designed and viable modular product for sophisticated machine controls in the mobile and marine hydraulics sectors. Many of the advanced features mentioned here are available as standard and from stock. This adds a lot of positive value to the whole supply chain which is an important consideration where delivery time challenges may cause machines to miss shipping deadlines.