The Functional Safety Revolution In Electrohydraulics

SIL & PL Certified Digital Proportional Valves

SIL & PL Certified Digital Proportional Valves

Digital technology has changed our lives and is a central focus of the industrial sector. It is the basis for fieldbuses, diagnostics and functional safety, and now it is essential to engineering smarter and safer industry 4.0 machines.

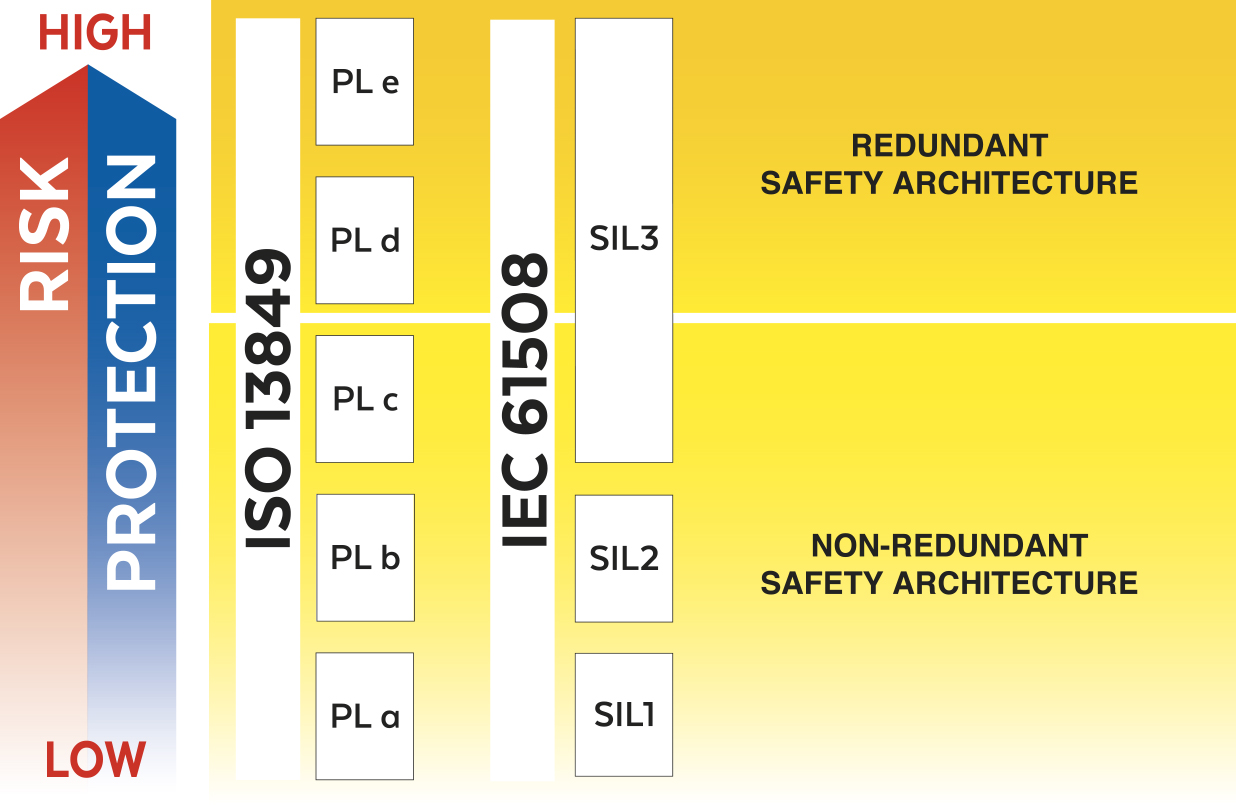

Functional safety is the ability to detect a potentially dangerous condition and activate a protective mechanism to prevent a hazardous event. The Machine Directive 2006/42/EC with relevant harmonized standards IEC 61508 safety integrity level (SIL) and ISO 13849 performance level (PL) define the general principles concerning machine safety that manufacturers must consider to limit risks related to machine operation.

Consequently, hydraulic system designers need to extend their competence and responsibility in dealing with safety regulations related to the risk prevention for workers and equipment in case of system fault or human error. They are also investing time and energy in components validation and the relative overall system certification process.

Certified safety valves eliminate the need for machine manufacturers to validate such components in compliance with the applicable safety standards. A considerable amount of time is saved during the machine design, resulting in a simplification of the system certification process.

Certified safety valves eliminate the need for machine manufacturers to validate such components in compliance with the applicable safety standards. A considerable amount of time is saved during the machine design, resulting in a simplification of the system certification process.

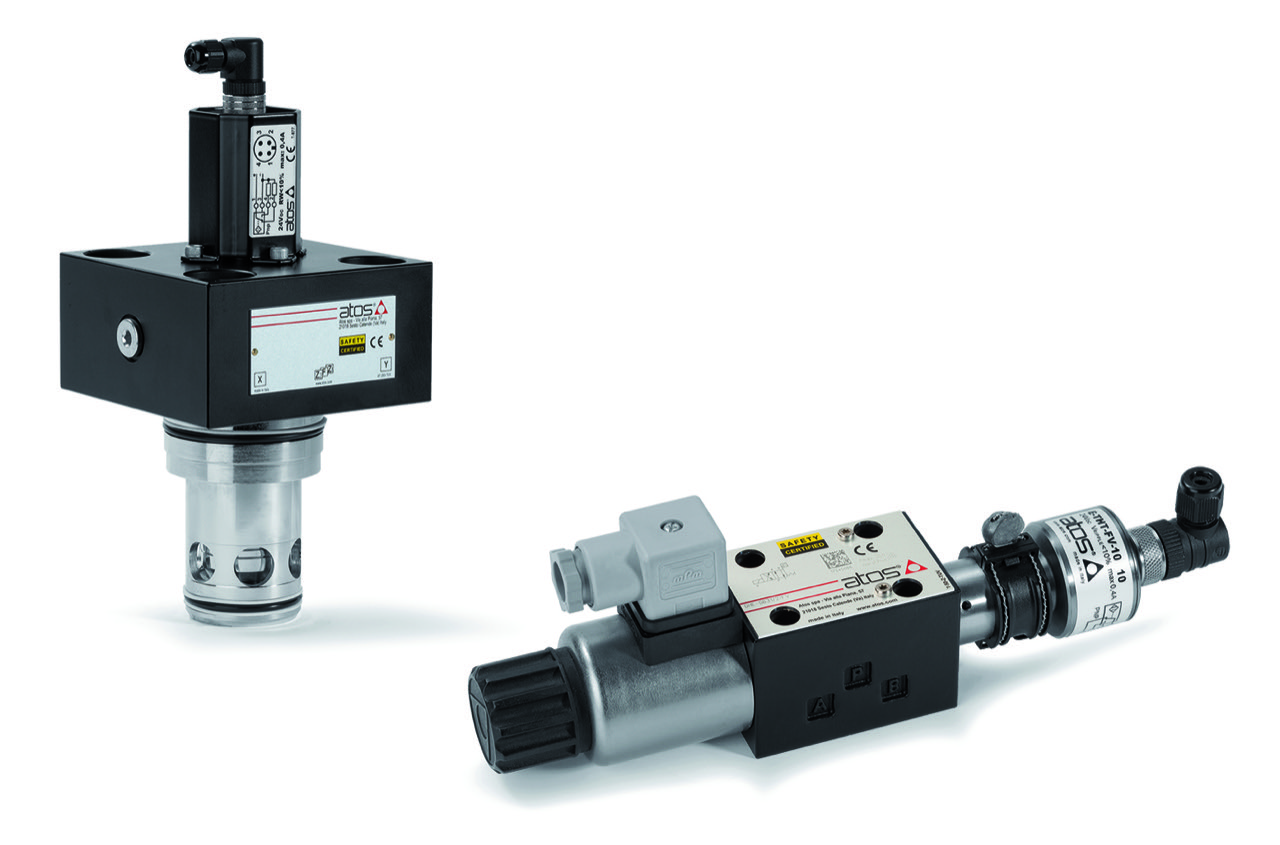

The standard solution foresees the use of on-off valves or cartridges with inductive safety sensors to monitor the spool or poppet position, information that the machine’s central unit collects to confirm the safe status of the valve.

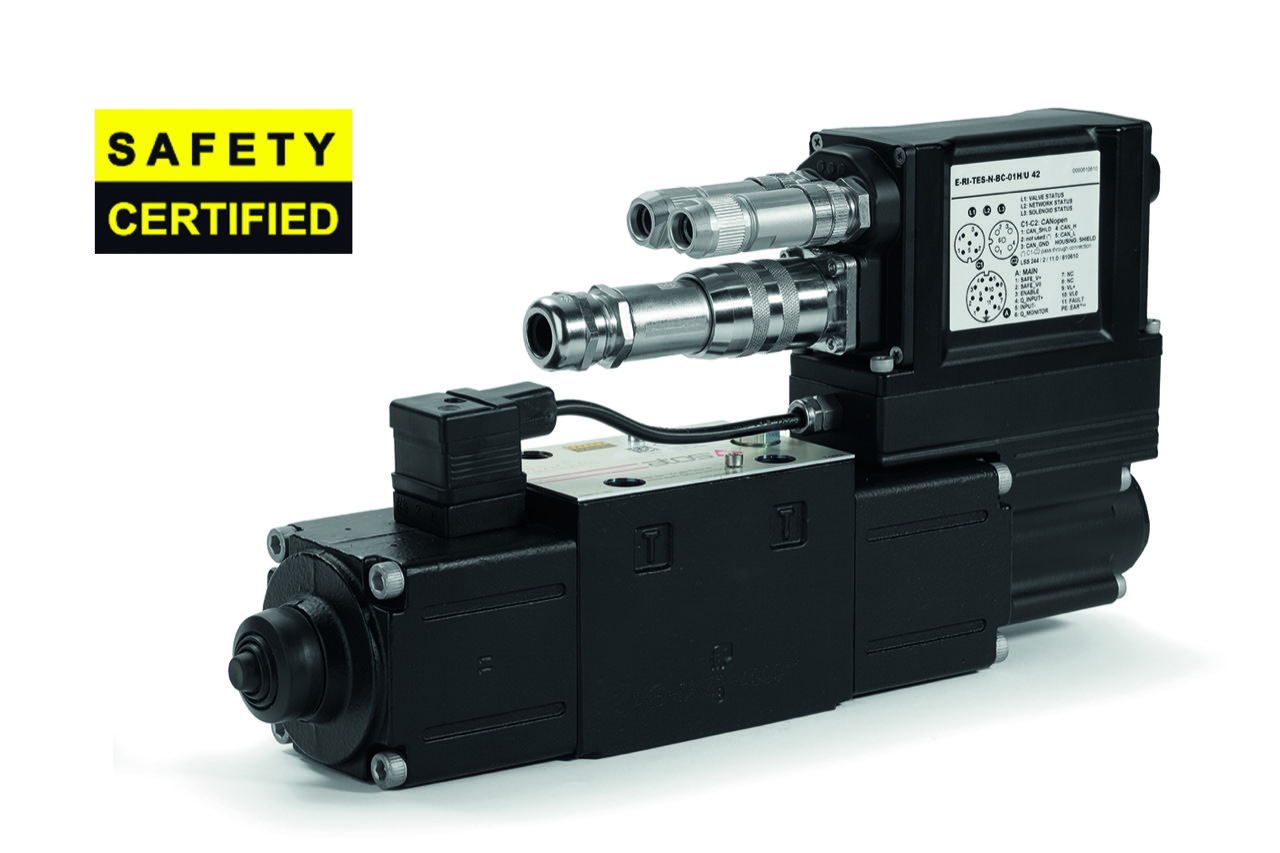

The innovation is represented by new digital proportional valves with onboard electronics designed for functional safety and certified by a notified body. They meet safety standards by performing the safety function in addition to axis motion control or standard valve regulation.

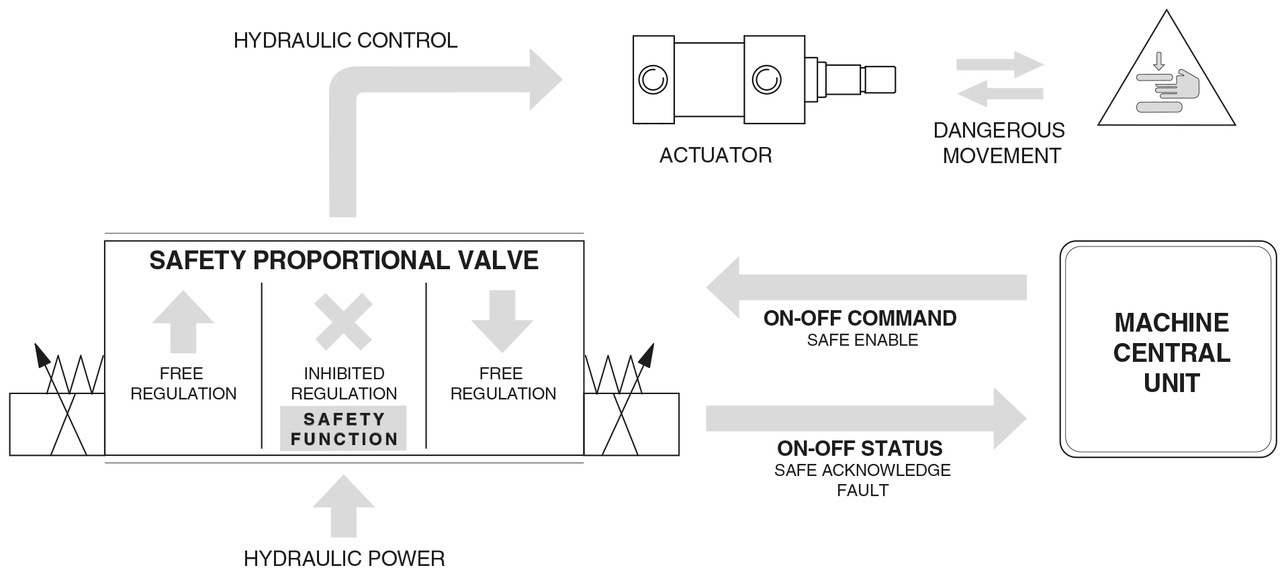

The safety function is operated to limit potential risks to equipment or operators by preventing dangerous movements of electrohydraulic axes during machine cycles. It is activated by the machine’s central unit in case of emergency and inhibits the regulation of proportional valve via on-off enable signals. The valve confirms when a safe spool position has been reached. This information is managed by the machine’s central unit as a “safe condition.”

Atos safety proportional valves are certified by TÜV in compliance with ISO 13849 up to category 4, PL e and IEC 61508 up to SIL 2 / SIL 3. The certification guarantees valve compliance with related safety norms and proves that the valve meets all requirements the SIL and PL levels claimed for the specific valve.

Atos safety proportional valves are certified by TÜV in compliance with ISO 13849 up to category 4, PL e and IEC 61508 up to SIL 2 / SIL 3. The certification guarantees valve compliance with related safety norms and proves that the valve meets all requirements the SIL and PL levels claimed for the specific valve.

Of course, overall system SIL and PL levels do not depend solely on the characteristics of a single component. Moreover, SIL and PL levels are determined by hydraulic system architecture, diagnostic coverage of that system, and the entire chain of safety-related parts that perform the safety function. Architecture plays a fundamental role; on-off and proportional controls can be integrated in redundant double channel systems to achieve higher safety levels, increasing the complexity of the systems.

In the last year, functional safety in hydraulic systems has become more important and is no longer an option; it’s now a basic requirement for every manufacturer. Certified valves support engineers in designing safer systems without wasting time in components validation versus the applicable safety standards.

In the last year, functional safety in hydraulic systems has become more important and is no longer an option; it’s now a basic requirement for every manufacturer. Certified valves support engineers in designing safer systems without wasting time in components validation versus the applicable safety standards.

For further information visit us at www.atos.com