Trelleborg to Showcase Expertise in Automated Fiber Placement Technology at SPE Offshore Europe

Trelleborg Sealing Solutions will showcase its expertise in advanced composites and Automated Fiber Placement (AFP) technology at the SPE Offshore Europe Conference and Exhibition, September 3-6 in Aberdeen, UK.

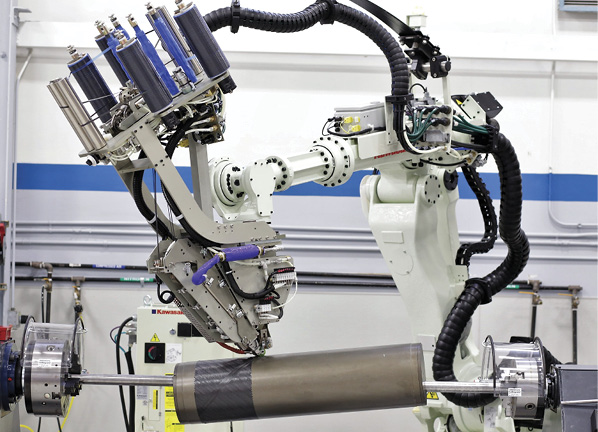

AFP is an additive manufacturing method for creating advanced composite structures using continuous-fiber tape. AFP allows for a high degree of control over processing by monitoring speed, temperature and pressure throughout the tape-placement process. This results in a repeatable, out-of-autoclave manufacturing process that reduces manual labor and processing time, while opening the door for the creation of complex geometries that are otherwise difficult to produce. Advanced composites are ideal for applications in oil and gas, aerospace, and other industries that require weight reduction and environmental resistance.

One example of an oil and gas development enabled by AFP is the high-performance carbon fiber composite hydraulic intensifier pump that Trelleborg Sealing Solutions helped a Houston-based oil field services company design and manufacture. This was for ultra-deep water environments where salt water corrosion, low temperatures, and extreme water pressure can cause catastrophic failures in equipment constructed with metal and other non-composite materials. The laser-based processing method significantly increases manufacturing through-put, which is critical for large scale projects that require hundreds or thousands of pounds of composite material per part.

Reid Hislop, Trelleborg Sealing Solutions Product Manager cites increased strength and lighter weight, along with more than three decades of experience in AFP technology as the major benefits of Trelleborg’s composite springs and advanced composite bearings for the often hostile environments of oil and gas applications.

Hislop says: “Most of the material we deal with is inert, which means that it survives in extreme conditions where other materials, such as metal, will corrode and fail. Our process starts with unidirectional prepreg composite material that enables us to lay down composite materials using AFP in a very precise geometry, producing an incredible amount of strength.

“Customers buy from Trelleborg Sealing Solutions because of the extremely high strength to weight ratio of its composites and the company’s long history of expertise in AFP design and manufacturing. Composites are not new but their adoption in the oil and gas industry is, which makes working with our team of experts incredibly important to our oil and gas customers.”

SPE Offshore Europe visitors will have the opportunity to meet with a number of Trelleborg Sealing Solutions experts on AFP manufacturing, composites and sealing applications.

SPE Offshore Europe is recognized by offshore professionals as Europe’s leading Exploration & Production event, with more than 900 suppliers on the exhibition floor.

Trelleborg Sealing Solutions will be in Hall 3, Stand 3B30. For further details of Trelleborg’s composite technology, visit www.tss.trelleborg.com.