Understanding Basic Types & Applications of Actuators

Linear Actuators

Cylinders may be single acting or double acting. Single acting cylinders exert a force due to air pressure only in one direction. Springs or gravity provide force in the opposite direction.

Single acting cylinders have some advantages over double acting cylinders. Spring-retracted and spring-extended air cylinders require pressure to only one end. Therefore, the piston requires only a unidirectional seal. If the cylinder is a spring-retracted type of cylinder, the rod bearing may not include a seal. Since the directional control valve is required only to pressurize and vent the same port, a three port rather than a five port directional valve may be used. The air in the opposite end of the single acting cylinder is vented with a breather.

Single acting cylinders have only one port to control speed in both directions. Without meter-out capability on the spring side, the single acting cylinder cannot resist overrunning loads.

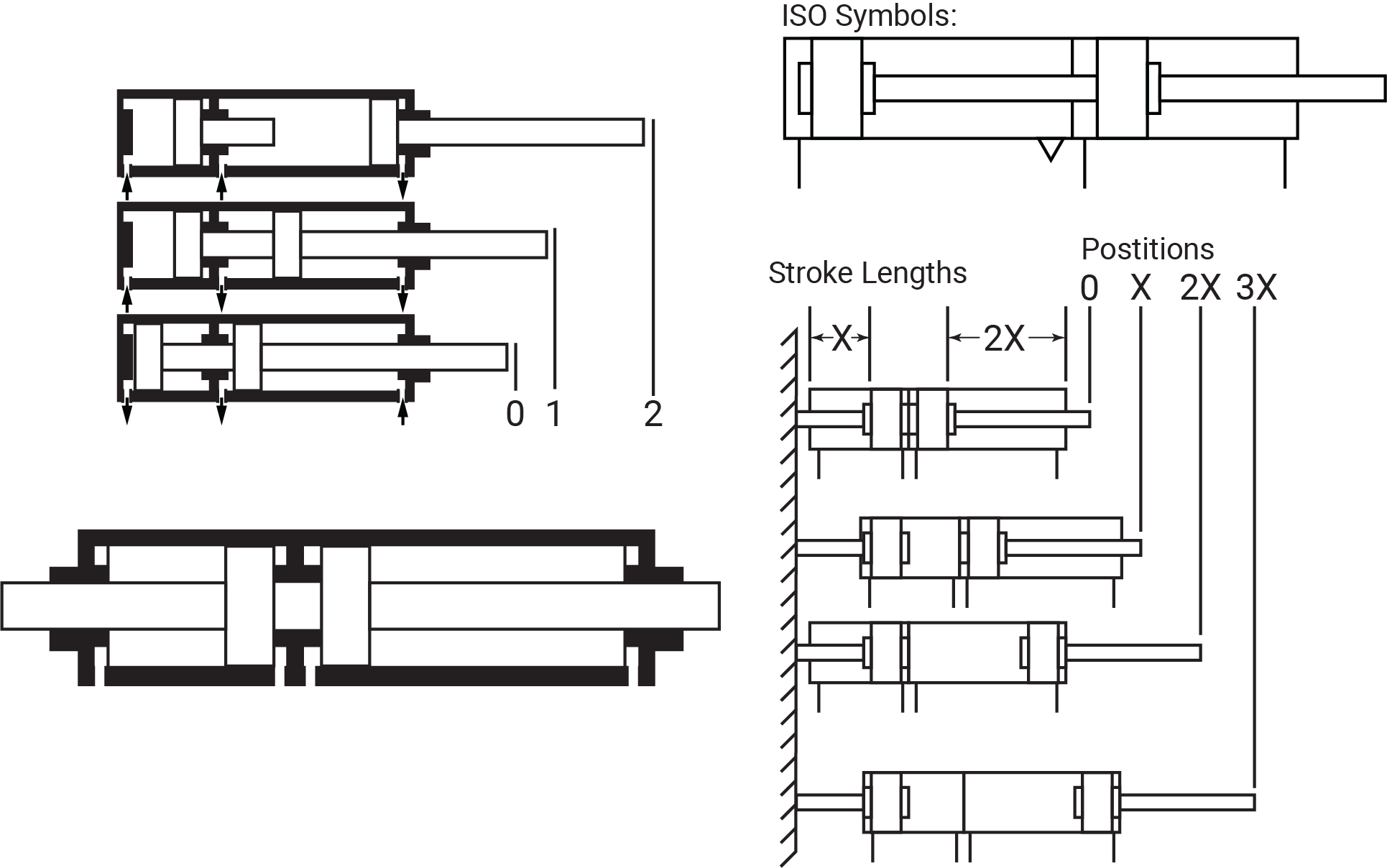

Double acting cylinders have pressure applied alternately to each side of the piston and therefore have a bidirectional piston seal, such as a double cup seal, a double lip seal, or an o-ring, which seals in both directions. A typical double acting cylinder has a single rod protruding through the rod end of the cylinder. Double rod cylinders have rods that protrude from each end. Double rods would allow the cylinder to move loads in either direction with the same force for a given pressure, pushing or pulling. Double acting cylinders also come as tandem units, meaning they have more than one piston.

Fig. 1-4 Single Acting Cylinder

Fig. 1-5 Double Acting Cylinder

Fig. 1-6 Principle of the Tandem Cylinder

If the pistons are hooked together on the same rod but in two pumping chambers, they work in tandem to exert greater force. If the two pistons are not on the same rod, the rods can work in opposite directions, for example, to provide four positions with various combinations of extension and retraction strokes. These are shown in Figures 1-6 and 1-7.

One major advantage of double acting cylinders is the meter-out capability to stiffen cylinder movement and resist overrunning loads. Double acting cylinders also offer more possibilities in system design, because they can be used as single or tandem units.

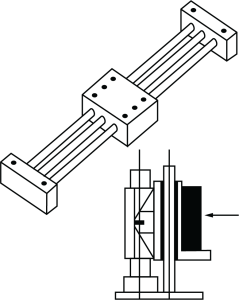

Rodless actuators are sized based upon the characteristics of the load they are carrying, operating speed, and actuator orientation. The center of gravity of the load, in relation to the center of the sliding block they are connected to, will impart both static and dynamic load moments to the bearings used in the actuator. A static load moment is the force exerted at a distance on the bearings when there is no motion. Dynamic load moments are imparted during motion events and are strongest at acceleration and deceleration. These load moments will be on the X, Y, and Z axes and are designated as pitch, roll, and yaw.

The collection of the correct data to properly size a rodless cylinder is necessary to ensure the static and dynamic forces on the bearings in the actuator are not exceeded. Data would include the operating pressure, stroke time, mass of the load, geometry of the load, dimensional relation of the load to the center of the rodless actuator’s sliding block, and actuator orientation.

Fig 1-7 Three and Four Position Cylinders

Rotary Actuators

(Motors and Limited Rotation)

Air motors and limited rotation actuators use compressed air to generate torque and provide rotary motion. An air motor can operate in both directions continuously while a limited rotation actuator typically rotates only 359° or less with the limit typically being 270°. Limited rotation actuators are described in Outcome 3.17 and sizing air motors is explained in Outcome 3.11. There are several reasons why air motors may be selected over an electric motor for a given application. Some of these reasons are:

- Air motors generally produce less heat than an electric motor.

- The speed of air motors can be easily controlled with simple flow controls.

- Air motors can be stalled at full torque without damage to the motor internals.

- The torque output of an air motor is easily regulated by varying supply air pressure.

- The power density of an air motor is typically greater than that of an equivalent.

- They can be operated in a volatile environment.

- Some disadvantages of air motors when compared to electric motors:

- Speed control is not as accurate.

- If an air supply source is not available then the cost to apply an air motor is higher compared to an electric motor.

- Depending on the cost of electricity, an air motor’s operating cost may be higher than an electric motor.

There are many different designs of air motors available for selection depending upon the application. As with hydraulic motors, these are classified as high speed, low torque motors or low speed, high torque motors.

Some of the most common designs of air motors used are rotary vane, axial and radial piston, turbine, and gerotor. Two other designs are used primary for special applications – V-type and diaphragm air motors.

Axial piston motors are used to provide high torque and accurate control at low speeds. They are also capable of generating high starting torque. Radial piston motors are used when there are very high starting loads as they produce the highest starting torque of any motor design. Both radial and axial piston motors require lubrication either supplied in the form of forced lubrication or using lubricated air. Radial piston motors must be mounted in a horizontal position to ensure adequate lubrication is present.

Rotary vane motors are used for low to medium power output applications. Their simple design and compact size make them ideal for use in portable power tools. They have a higher power density than comparable piston motors. While there are vane motor designs that can operate with non-lubricated air, the motors most commonly found must use lubricated air and are less sensitive to mounting orientation than piston motors.

Gerotor motors are used to provide high torque at low speed without needed additional gearing. The low inertia of the internal rotating group provides for instant starting and stopping or change in direction. The design of the gerotor motor prevents coasting or being back driven and may eliminate the need for an external brake.

Turbine motors are designed such that there is a minimum of internal friction and thus require little lubrication. They are typically used where the application requires very high speed, but the starting torques is low. These are commonly applied to dentist drills or as starters for jet engines. They are more tolerant of contaminates in the air than other motors due to their design. Operation of a turbine air motor involves a nozzle that guides and meters air to a turbine wheel/rotor. The nozzle changes high-pressure, low-velocity air flow to a low-pressure, high-velocity air stream directed against the turbine wheel to cause rotation.

The overall efficiency of a motor is determined by the ratio of the actual output power to the theoretical output power. The highest overall efficiency air motor is typically a turbine design due to the lack of sliding parts contact which result in internal friction and lower the efficiency.

The theoretical torque output for an air motor of given displacement is a function of the differential pressure. This means that torque theoretically does not vary with a change of speed. In actual practice, as air flow increases through the motor, pressure losses in the inlet and outlet lines along with internal leakage consume a greater portion of the air supply. In practice, torque reaches its greatest value shortly beyond zero speed and drops off rapidly until it reaches zero at the maximum rated speed of the motor at no-load.

The maximum torque the motor can produce under load is referred to as the starting torque. Typically, this is about 75% of the rated stall torque. It takes more torque to start a motor rotating under load than to keep it running. If the load on the air motor exceeds the starting torque capability, the motor will not start to rotate.

Test Your Skills

1. Which one of the following is an advantage of a double acting air cylinder over a single acting, gravity-returned air cylinder?

a. Reduced air consumption.

b. Smaller bore can be used.

c. Force can be controlled in both directions.

d. Less wear than double acting.

e. Cycle rate is faster during operation.

2. The magnetically coupled rodless cylinder shown is to be used to move the load vertically. The load and support fixture have a combined weight of 100 N. Which additional factor listed would need to be considered for the rodless cylinder selection?

2. The magnetically coupled rodless cylinder shown is to be used to move the load vertically. The load and support fixture have a combined weight of 100 N. Which additional factor listed would need to be considered for the rodless cylinder selection?

a. Available air pressure.

b. Peak air flow required.

c. Cylinder side load on rod bearings.

d. Magnetic coupling strength.

e. Acceleration and deceleration forces.