Using Smart Labels to Label and Identify Hydraulic Hoses

By Jeff L. Bassindale, VP of Sales-Partner, DFI Solutions in Print.

Labeling hydraulic hoses has become essential in the Hydraulic Hose & heavy equipment industry today. Imagine owning or renting heavy equipment where the hourly cost maybe upwards of $1,600 per hour, then the hose blows or fails. It is imperative that the hose gets replaced asap. How that specific hose is labeled or tagged will have a huge impact on how fast it can get replaced.

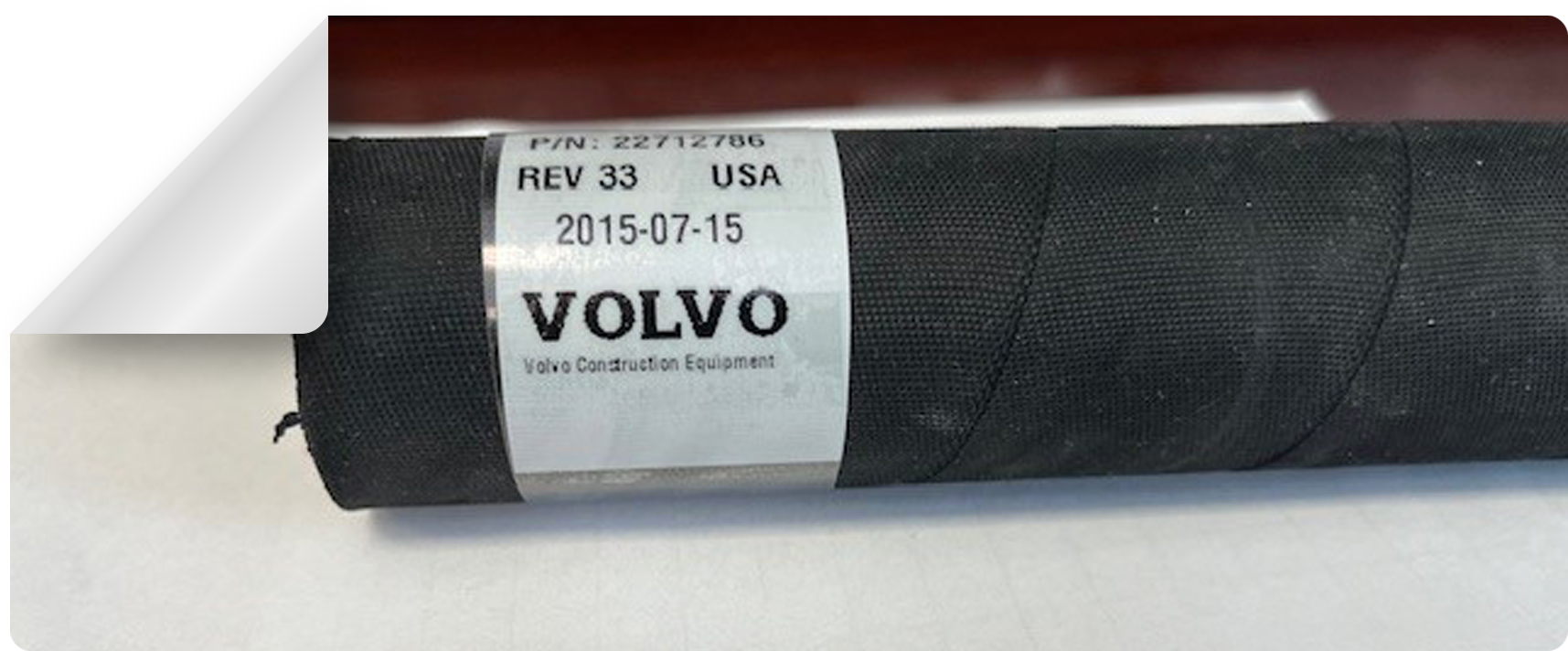

Photography courtesy of DFI Solutions in Print

Several years ago, many hoses were tagged with a metal band with part number stamped in it, this number had to be called in or the hose had to be brought in to the dealer or shop for a replacement so they could match the hose needed.

Today this can be accomplished by scanning a 2D barcode or QR code printed on a label which takes the person scanning or needing the hose to the dealer’s website with the correct part number.

Because the part number is clearly labeled on the hose, the part number can be called in or emailed to the dealer. In most cases, by the time the user gets to the dealer the hose has been made and they can head back to the work site.

Because the part number is clearly labeled on the hose, the part number can be called in or emailed to the dealer. In most cases, by the time the user gets to the dealer the hose has been made and they can head back to the work site.

The overall cost of the equipment that is shut down by failure of a hose can cost the operator or his company thousands of dollars if the equipment remains down, not to mention rescheduling the job and other contractors affected by the delay.

Many refer to this type of label as a Smart Label because it contains much key information. Users print a label containing a QR code or a 2-D barcode on the label (which can contain a paragraph of information). In most cases, the dealer that is renting the equipment can embed their website and part number of that particular hose in the 2-D barcode. The QR code while very popular, as most people recognize it in the marketplace, it isn’t recommended for curved surfaces and can cause issues reading in the field. The QR code can be read by smart phones, unless the curvature of the hose prohibits a clear read. A better choice is a 2-D barcode such as a datamatrix rectangular barcode. This bar code symbology is proven in the field.

There are many solutions on the market today offering this label solution, allowing the user to print their own hose labels with all of the pertinent information needed.

When the correct material is used, it provides these main benefits:

- Self-laminated label with protection from all solvents

- Chemical, oil, brake cleaner and water resistant

- UV resistant, it won’t fade in the sun

- Durable material with aggressive adhesive

- Made to last 5-7 years outdoors in most environments

Typically the label will contain the following information:

- Dealer Name or contact info (maybe embedded in a 2D bar code)

- Logo

- Part number or hose description

- Date

- Customer name

- Hose description

- Other static or variable information

Many of these solutions can be standalone without connecting to a host system. However there are options to print from a network as well.

Typical Solution

To print variable information on a durable material typically you will use a Thermal Transfer Printing process which uses a printer such as a Zebra, TSC, Honeywell or SATO thermal transfer printer. These printers use heat to transfer ink from a specialized ribbon to a durable outdoor material with aggressive durable adhesive.

The total solution can be relatively inexpensive with a standalone printer ranging in cost from $600 to $2000, depending on type of printer and the volume of labels need to be printed daily.

These printers are the workhorse of manufacturing & industrial bar code labeling applications worldwide.

Laser Printers

Those who already have a laser printer may see them as an inexpensive option but there are some obstacles. The material to be printed must be available in sheets that can be used by the printer. This limits the type and quality of the available material.

It’s doable but requires special converting of durable material which many times typically aren’t converted into sheets, which is what the laser printer needs as media.

Photography courtesy of DFI Solutions in Print

Label Design Software

Label design software such as Bartender or NiceLabel can be used to design the format of the label itself, incorporating bar codes, logos and special fonts.

The software will allow specific fields to be designated as fixed or static fields or data or fields that will be variable (or change like a part number).

These variable fields can be populated with a keyboard or dumped from a database.

Label Material

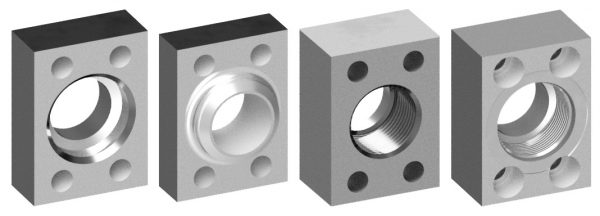

The label needs to be a durable synthetic material that can withstand a minimum of 140 C or 280 °F. An extremely aggressive adhesive on the label that allows proper adhesion to the hose. Typically, this label material is clear with a printed white square allowing for the data to be printed on the white square and the clear tail wraps around itself, self-laminating the hose label protecting the variable information from solvents.

Sometimes users elect to color code types of hoses using the label stock. The labels can be provided with a preprinted color bar, sometimes designating a year the hose was made or type of hose.

Photography courtesy of DFI Solutions in Print

Vinyl is not recommended because it will not withstand the 140C or 275F requirement.

However people do it anyway because it’s easy to get, and can be cheaper.

The poly material used in most applications should be in the .04 to .07 per label price range making it a very inexpensive way to label hoses.

NOTE: As in most cases with everything people spend their money on, many users try to get by with the cheapest option available, resulting in labels peeling off and breaking when exposed to harsh environments. What’s the point in investing in a labeling process when it failed because you saved 25% on label material?

The label placement

Label placement on the hose is critical and should be adjacent to the coupling which provides a firm rigid area without bending and compromising the label. In addition many current users place 1 label at each end of the hose insuring that there will be 1 label with good access when it comes time to read the bar code or identify the part number.

Hose coverings & protective add ons

Many times hoses that are in precarious position or vulnerable to abrasion etc. are covered with a protective covering made out of a sheath of cloth, or other material preventing the hose to scrape or be compromised. In these cases you typically see another sacrificial label applied to the protective covering that can be seen without removing the covering.

RFID Tags

Radio Frequency Identification (RFID) technology is becoming increasingly used in the marketplace with the cost of implementing dropping. It is becoming mandatory in certain large box retailers such as Wal-Mart, Dicks, Home Depot etc.

The next generation of Smart Labels probably will contain a RFID tag or a NFC label which probably is in the .30- .50 each price range and requires a more expensive printer to encode the tags, and, in the case of RFID tag, requires a specialized RFID reader as well.

The RFID tags need to be printed on similar Thermal Transfer printers but with special RFID capability . (Printers $1900-$2800). The label contains an antenna or chip that needs to have the data encoded. The labels are then applied as normal labels are.

The RFID tags can only be read with a RFID reader or scanner ($1800-$2400).

NOTE: this can be the game changer since it would require anyone in the field to have access to such a reader.

Challenge: Because the RFID hose tags maybe in close proximity to heavy iron, or behind enclosed areas the readability maybe a huge challenge and would need to be thoroughly tested.

The retailer can walk down an isle, scan the shelf and get valuable inventory information. That simply isn’t the case with heavy equipment in the field.

If this is something you want to implement I would strongly recommend a solution provider that can provide the Total Solution, the printer, software, labels, ribbons and support needed to keep you supported during this project.