Figure It Out: New Motor Stalls and Pops Overloads

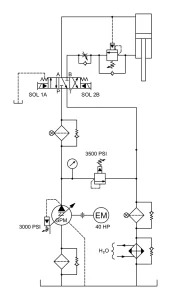

A system that worked well for many years needed its electric motor changed. The company bought a 40-horsepower electric motor, but it was a different brand than the original one. After installing it and starting the system, the motor stalled and popped the overloads. The company discovered that the system could only run if they lowered the compensator setting. The operator could then increase the compensator, and it would run fine until the motor stopped. The company continued this start-up procedure of lowering the compensator to run the system.

A system that worked well for many years needed its electric motor changed. The company bought a 40-horsepower electric motor, but it was a different brand than the original one. After installing it and starting the system, the motor stalled and popped the overloads. The company discovered that the system could only run if they lowered the compensator setting. The operator could then increase the compensator, and it would run fine until the motor stopped. The company continued this start-up procedure of lowering the compensator to run the system.

When troubleshooting, workers noticed that the amp draw spiked higher than the motor’s nameplate rating of 40 horsepower. When starting the system, it drew even higher, causing the overloads to trip.

What could be the problem?

See Solution

When replacing the electric motor, the company did not notice that the old motor had a 1.2 service factor, which was enough pull-out power. The new motor, however, had a 1.0 service factor and a lower pull-out power. Adding a solenoid unloading relief valve reduced the motor’s start-up load.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.