Using Transfer Barrier Bladder Accumulators for Subsea Compensation Control

Adobe Stock | yamonstro

By Richard Kendall, Executive Vice President, Accumulators, Inc.

Bladder accumulators have been a cornerstone of the offshore oil industry for decades, playing a critical role in a variety of applications. These versatile devices are commonly used to provide emergency power for blowout preventer (BOP) hydraulic power units, ensuring safety and operational continuity during critical moments. Other applications using accumulators include shock absorbers for mud pumps, excess power for control panels, and other offerings. In recent years, the offshore oil industry has witnessed significant advancements in deepwater drilling technologies. As a result, fluid power engineers have been tasked with overcoming a host of challenges relative to the effects of hydrostatic head pressures. Furthermore, the thermal expansion and contraction of high water-based fluids require precise engineering solutions to maintain system integrity and efficiency.

Many of the functions of subsea control systems, integral to modern offshore operations, heavily rely on the use of hydraulic cylinders. As a result, these operations are prone to challenges with environmentally safe hydraulic fluids, typically of the 97/3 composition of 97% water and 3% water-soluble glycol. These are designed to minimize environmental impact while maintaining performance.

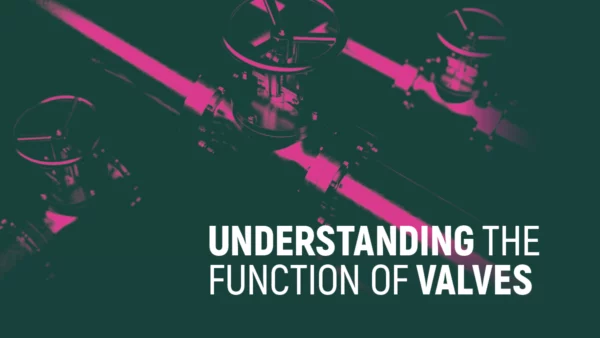

1 Quart Subsea Transfer Barrier, 3000 psi version As seen in the photo, the top end of the transfer barrier where the compensating fluid is connected has a perforated tube and coupling. The seawater side has a stainless-steel mesh filter to eliminate seawater contamination. All transfer barrier materials are stainless steel. The shell is high-strength chrome-moly steel that is electroless nickel plated or has a phenolic coating on the ID and marine epoxy paint on the OD. Sizes range from 1 quart to 15 gallons, up to 6000 psi.

All actuators undergo rigorous testing on the surface before a system is deployed to depths ranging from 150 to 3,000 meters (500 to 10,000 feet). These tests ensure reliability and performance under varying conditions, as surface temperatures can fluctuate significantly depending on the season and geographical location. Temperature variations from 38°C (100°F) at the surface to as low as 1°C (34°F) at depth are where the transfer barrier accumulator comes into play. This is where the transfer barrier accumulator plays a critical role, acting as a reservoir to accommodate the thermal expansion and contraction of the high water-based hydraulic fluid.

Initially, compensation for fluid expansion and contraction posed a significant engineering obstacle. Fluid expansion caused by high temperatures could lead to over-pressurization, necessitating the use of mechanical relief valves to alleviate excess pressure. Fluid contraction caused by frigid conditions would create problems for the actuators, such as not having enough fluid on demand.

When properly sized, transfer barrier accumulators integrate seamlessly into subsea pods, which house sophisticated equipment, including electronic components vital for efficient operation. When lowered to depth, the housings cannot withstand external pressure from the immense hydrostatic pressure exerted by seawater at depth. Therefore, the housings are filled with a dielectric fluid. A transfer barrier accumulator is connected to the housing, with the bladder inside exposed to the dielectric fluid and the outer component of the barrier exposed to seawater.

As the equipment is lowered to depth, the barrier transfers the seawater pressure to the dielectric fluid. This pressure transfer mechanism eliminates the risk of housing collapse due to hydrostatic head pressure, ensuring that there is virtually no pressure differential across the pod housing wall. The housing is always protected from collapse due to the transfer barrier accumulator automatically adjusting seawater pressure on the non-seawater side to maintain steadiness.

Beyond their role in pressure compensation, transfer barrier accumulators enhance the longevity and reliability of subsea systems. By preventing over-pressurization and under-supply of hydraulic fluid, they ensure that actuators and other hydraulic components function consistently, even under the most extreme conditions.

As subsea exploration and production activities continue to expand into deeper and more demanding environments, the role of transfer barrier accumulators will only grow in significance. Future advancements may lead to even more efficient designs, capable of withstanding greater pressure and temperature while enhancing system reliability. These innovations will be essential for ensuring safe, sustainable operations in the future.