Vacuum Gripping and Pick & Place for Wood Surfaces

The following is an opinion article written by Dane Spivak of Davasol Incorporated, an industrial brand management firm with many clients, including Vacuforce LLC, which partnered in the writing of this article. Contact Dane Spivak by email at dspivak@davasol.com.

Vacuum gripping systems are used in the wood industry for pick & place applications as well as vacuum hold down for machining and processing. Wooden parts come in many shapes and sizes, and, more relevant to this article, differ in surface characteristics where vacuum cups need to seal. Gripping systems start from the pump producing vacuum and end at the cups sealing against the product surface. Components in between are used to tie together a fully functioning system. Many applications share the same basic parts but require different design techniques to produce a reliable output. The following article touches on these facets.

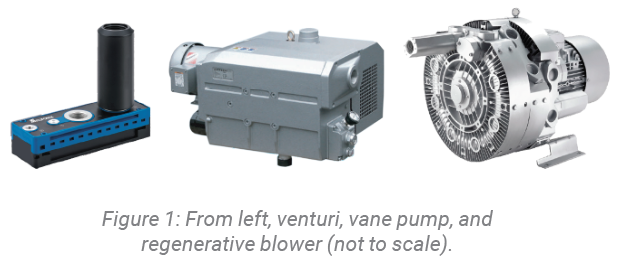

Vacuum sources

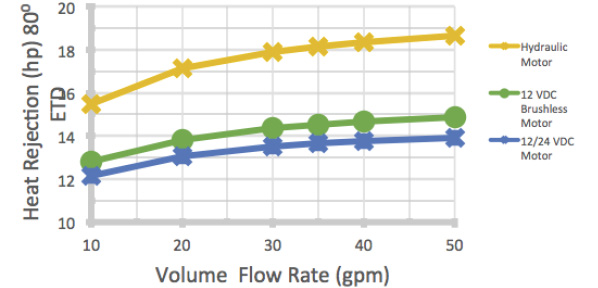

A variety of vacuum pump types can be used for wood gripping. However, most popular methods include venturi generators, rotary vane pumps, and regenerative blowers. Venturis use compressed air to generate vacuum, which can be a good choice depending on the application and the user’s accessibility to compressed air. Despite their small size, venturis can reach fairly high vacuum levels, up to 27 inHg (90% vacuum). Vane pumps are also known for their comparatively higher vacuum levels for vacuum gripping applications as they can reach over 29 inHg (96% vacuum). Vane pumps are powered by electric motors unlike the venturi. The electrically driven regenerative blowers are known for their high flow capacities and are more often used for larger systems or applications with significant leakage. Although their maximum vacuum levels can vary from 0-21 inHg (70% vacuum), their energy is put into the vacuum flow, which can prove to be beneficial to the system needs. Figure 1 gives examples of each unit. Their appropriate uses will be discussed in more detail later in this article.

Filters

Continuing through the vacuum system, vacuum filters would be most appropriate to discuss next. Vacuum filters are used to protect pumps or venturis and are often close coupled to the vacuum unit itself. The filter protects the pump from unwanted dust, debris, oil, water, and other unwanted particulates. This is important in wood handling as the environments can be quite dirty. Figure 2 shows various vacuum inlet filters. Prefilters are also used in the wood industry to protect other components in the system. Prefilters are installed right after the vacuum cup or as close as possible to the application to filter out the air as early as possible before flowing through the system. A good exercise in wood applications is to oversize the filters so they can collect and handle more particulates. This allows for less maintenance and less potential flow restrictions.

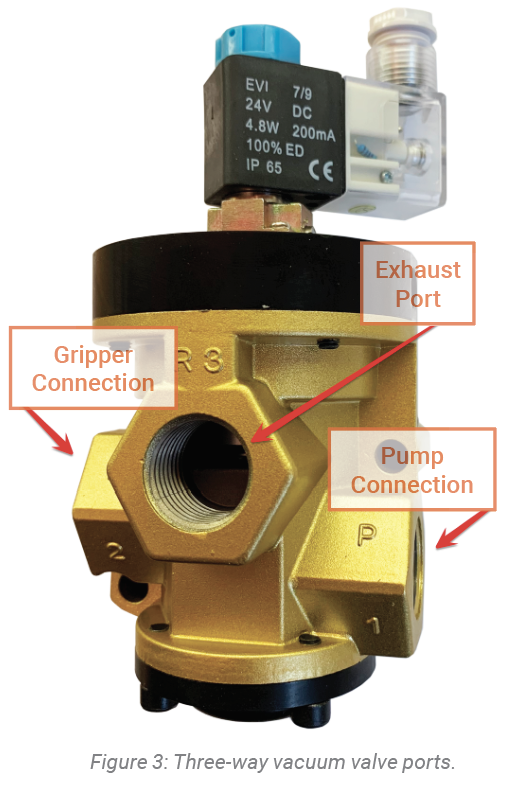

Control valves

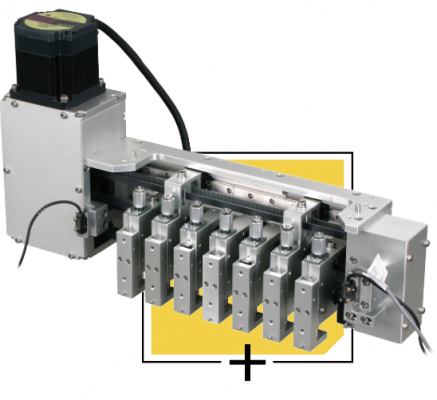

Vacuum control valves come after the pump and filter. Vacuum valves are the controllers of the system that turns vacuum on by connecting the pump to the cups, which grips and holds the wood. When the valve position is switched off, it shuts off vacuum by blocking the vacuum source from the cups and exhausting vacuum in the cups to atmospheric air, which releases the wood. Figure 3 gives an example of a vacuum valve. Vacuum valves should be sized according to the application flow requirement and are an important justification for prefilters. In some applications, a vacuum valve can have a filter on its exhaust port since atmospheric air is sucked into the valve to release the product, which introduces unfiltered ambient air to the system. Venturis do not necessarily require a vacuum valve as they can be turned on and off with pneumatic valves.

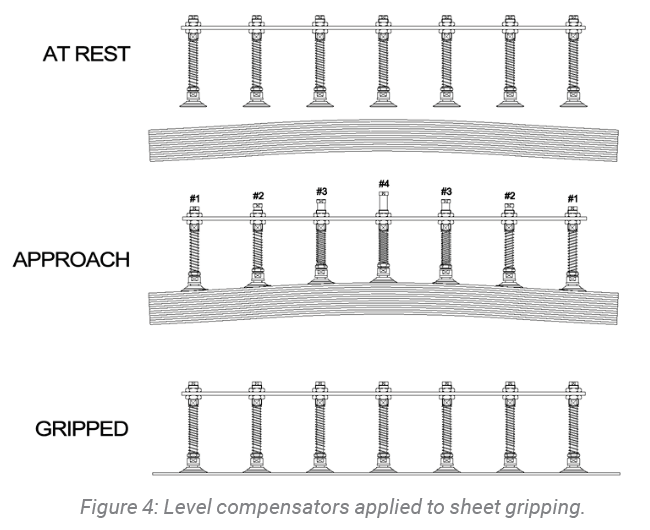

Level compensators

As we inch closer to vacuum cups at the end point of the system, level compensators come into play. Level compensators are spring loaded cup mounts that provide vertical compensation for the vacuum cups to establish a seal on the product surface. Level compensators are particularly useful for wood sheets that can bend and curve along the surface, creating different height points in local areas. The compensators allow the spring to compress and all cups to make contact against the surface. They are also used for machine height compensation for destacking applications. Compensators come in many thread sizes and stroke lengths. Figure 4 illustrates their functionality. Note that compensators should only be used in vertical lifting applications. They generally do not perform as well in shear or hold-down applications.

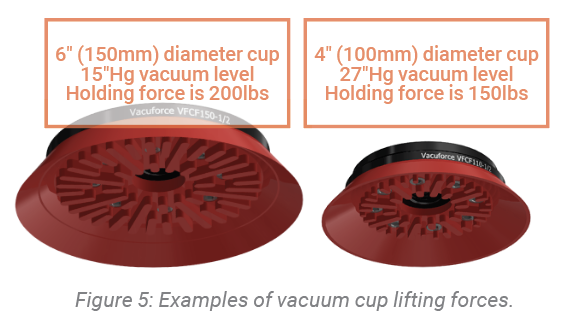

Suction cups

Lastly, the vacuum cups seal against the wood surface and generate the gripping force. The cup diameter and final vacuum level determine the lifting force for each cup. The weight of the wood is rarely an issue as most wood applications offer significant surface area where cups can seal. A 4-inch (100 mm) diameter vacuum cup under 27 inHg (90% vacuum) has a theoretical lifting capacity of around 160 pounds. Assuming a safety factor of 4, that leaves us with about 40 pounds per 4-inch cup. Another example: a 6-inch (150 mm) cup under 15 inHg (50% vacuum) has a theoretical lifting capacity of approximately 200 pounds – about 50 pounds after a safety factor of 4 is applied. Figure 5 demonstrates the applied lifting forces previously described. Vacuum cups should be sized correctly, but most importantly their material should be chosen wisely to ensure it is long lasting, nonmarking, and creates a good seal. Cup material selection will be discussed in more detail in the next few paragraphs.

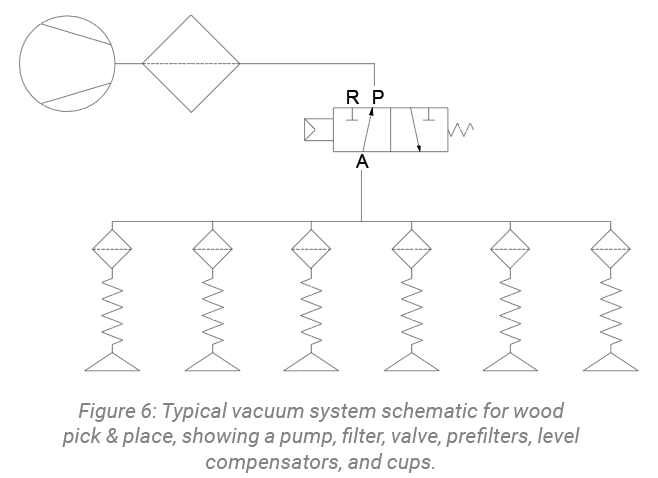

The basic system

Now that we have defined our components, we can put together a schematic of a complete system, as shown in figure 6. This system excludes other potential components but provides a basic design for wood gripping. Vacuum sensors are useful for part presence by detecting the cups sealing or safety measures to ensure the vacuum level is high enough to proceed with the application. Pneumatic blow-off can be useful to provide a quicker or more aggressive product release. Blow-off can also be used to push away dust before the cups contact the wood. This helps with the seal and prevents more dust from entering the vacuum system. These components are not shown in figure 6.

Flat and smooth surfaces

Flat and smooth surfaces are ideal for vacuum cup gripping. They provide an area for cups to seal with ease and allow for little to no leakage. Because of that, not a lot of flow is required from the vacuum pump, and so venturis or vane pumps are generally chosen as the source. The reduced leakage helps maintain higher vacuum levels for a confident grip and the need for less cups overall. Just about any vacuum cup could seal against such a surface, so in this case it is ideal to select a cup that is durable and nonmarking. Polyurethane material is a great choice that checks off both boxes but nitrile can also be an adequate selection. Flat cups typically offer longer life and overall gripping stability, though a single bellows model may be preferred for some height and angular compensation. Figure 7 gives examples of the cup options. These design approaches can be applied to wood surfaces with a little texture and curvature, within reason.

Rough or textured surfaces

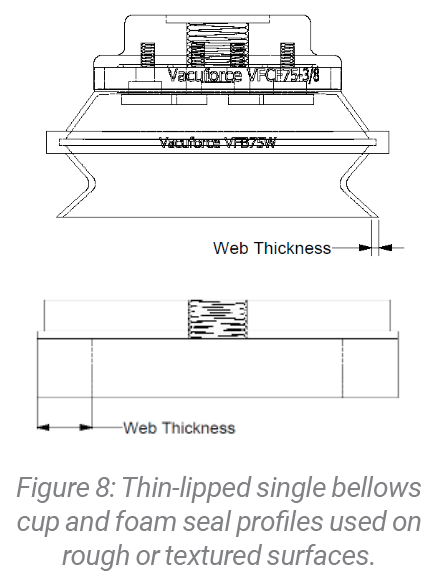

Rough or textured surfaces with more aggressive features introduce the possibility of air leaking into the system if the cups do not provide a near-perfect seal. There are two ways to compensate for the potential leakage. One way is to use a higher-flowing vacuum pump that removes the leaking air from the system at a faster rate than what is leaking through the cup seal and consequently increases the final vacuum level. This is a scenario in which a regenerative blower should be considered, although venturis and vane pumps can work depending on the severity of the leakage. The other approach is to use softer Durometer vacuum cups with thinner lips to allow the cups to conform better to the surface and reduce leakage. Sometimes rubber cups simply cannot offer a good seal without a very large pump, so a closed-cell foam cup is used instead as it can deform into the surface irregularities and offer a better seal than regular rubber cups. Foam can certainly be effective at sealing to surfaces, but the tradeoff is that it does not last nearly as long as a rubber cup. Foam wears away much quicker and can become a concern for maintenance teams and machine downtime. Therefore, foam cups should only be used if absolutely necessary. Figure 8 shows softer thin-lipped cups and foam seals.

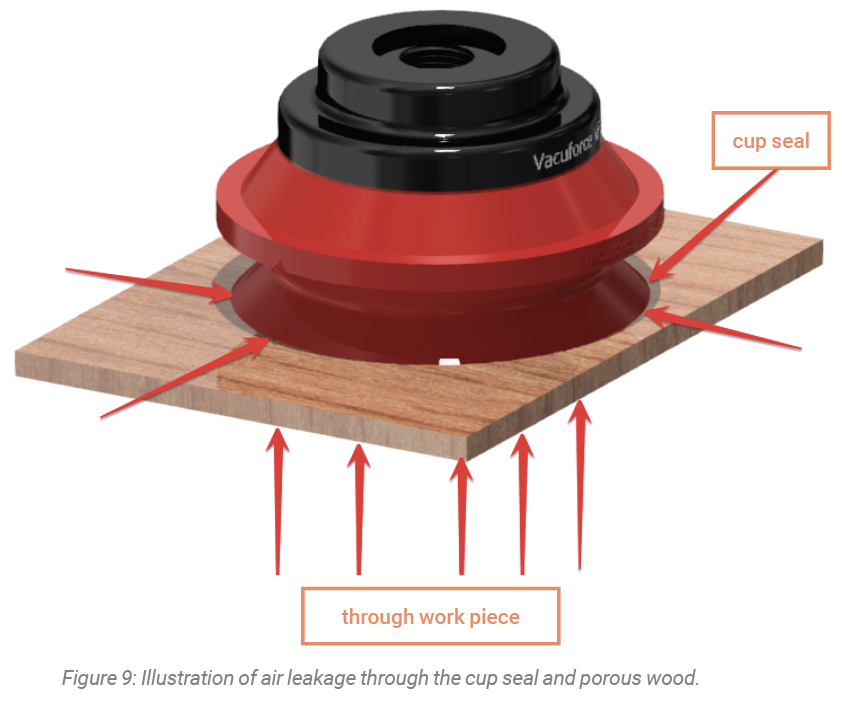

Porous surfaces

Porous wood surfaces present a further challenge with vacuum gripping as leakage comes not only through the cup seal against the surface but also through the wood itself. So regardless of what cup model or material is being used, impactful leakage is unavoidable. Figure 9 illustrates this scenario. A suitable sealing cup, as discussed previously, can reduce leakage but cannot eliminate it entirely. Because of that, regenerative blowers are usually the preferred choice for porous surfaces and at times arguably the only choice for the system to work with a reasonable design. Although venturis and vane pumps can attain higher vacuum levels, the final vacuum levels are limited and even zeroed due to lack of flow. Zero vacuum is the result of the leakage flow being equal to the flow produced by the pump. In this case the pump cannot create a pressure differential (vacuum level). However, blowers provide relatively higher flows at deeper vacuum levels, and so the final vacuum level from a blower can be higher as a result of its flow capabilities. For sheet destacking of porous products, vacuum can sometimes pull through the wood and move the sheet below the top product being lifted. This can be prevented by using air knives between the sheets and side brushes or clamps for separation. Breaking the seal between two sheets can also be carried out by lifting one side slightly to peel off the top sheet.

The basic breakdown of a vacuum gripping system for wood includes the pumps, filters, valves, level compensators, and vacuum cups. Additional components such as sensors and blow-off valves are used based on preference and design needs. The wood surface texture and porosity determine the selection of the cup material and model, and different pump types and flow performances help generate acceptable vacuum levels. This article is a general guide and opinion piece. Professional assistance is recommended for specific application advice.