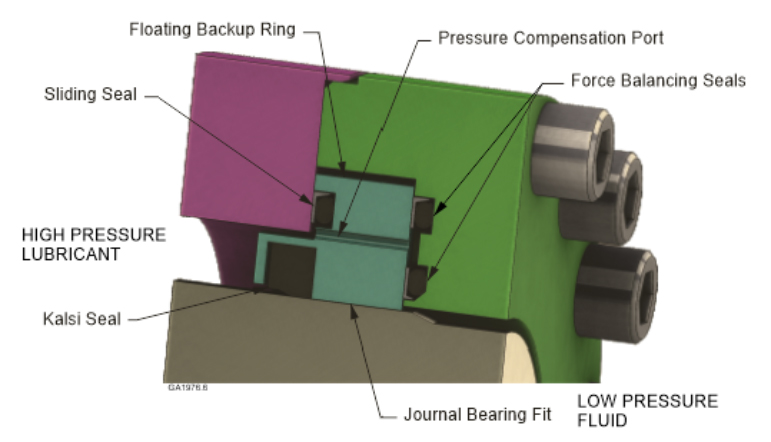

High Pressure Rotary Seal Assembly

SPONSORED CONTENT

Kalsi Engineering is pleased to announce the latest innovation in high pressure rotary sealing. Our patented floating metal backup ring promotes maximum high-pressure seal performance by moving laterally to accommodate shaft runout and misalignment while providing the smallest possible extrusion gap clearance. The small clearance improves seal support, resulting in less pressure-related seal extrusion damage. The backup ring has a journal bearing type fit with the shaft. This fit defines the extrusion gap clearance for the rotary seal and aligns the backup ring on the shaft. The Kalsi brand rotary seal has hydrodynamic waves that pump a thin film of lubricant through the dynamic sealing interface during rotation. This rotationally driven pumping action reduces friction, wear, and seal generated heat, and lubricates the journal bearing interface between the backup ring and the shaft. The high pressure acts on equally sized sealed areas on both ends of the backup ring. This arrangement applies equal oppositely acting hydraulic forces to the backup ring, resulting in axial force balance. This leaves the backup ring free to move laterally to accommodate shaft misalignment, dynamic runout, and lateral deflection without risk of destructive heavily loaded metal to metal contact between the backup ring and the shaft. Contact us today to learn how our floating backup ring technology can increase the high-pressure performance of your rotary equipment.

For further information on the Kalsi Engineering floating backup ring or Kalsi Seal technologies, visit us at www.kalsi.com

Dear Sir

We require high pressure seal for 100 bar.

ID- 150 MM

OD-180 MM

T- 10 MM

PRESSURE:- 80 BAR

QUANTITY- 16 NOS.

PLEASE QUOTE WITH DELIVERY TIME.

AWAITING EARLIEST RESPONSE.

Best Regards,

Thomas Deepth

+91 6366 698331

thomas@abbamarine.in

ABBA MARINES INDIA PVT. LTD.

Office 501, 5th Floor,

Steel Chambers,

Devji Ratansey Marg,

Masjid Bander (E),

Mumbai- 400 009

Tel:- +91 22 4979 6828

http://www.abbamarine.in