Air Receiver Tanks in Compressed Air Systems

by David Connaughton, Product Marketing Manager, Industrial Gas Filtration and Generation Division, Parker Hannifin

by David Connaughton, Product Marketing Manager, Industrial Gas Filtration and Generation Division, Parker Hannifin

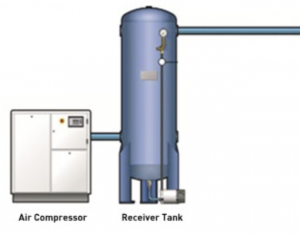

An air receiver tank is an integral and important part of any compressed air system. A receiver tank is typically sized at 2 gal/scfm and increased to 4-10 gal/scfm of flow if there are big demand swings or surges. So if a compressor has a rating of 25 scfm at 100 psig, the receiver tank should be at least 50 gallons up to 250 gallons if there are large surges.

In a compressed air system, a receiver tank provides several benefits.

- The receiver tank acts as a reservoir of compressed air for peak demands.

- It helps remove water from the system by allowing the air a chance to cool.

- It minimizes pulsation in the system caused by a reciprocating compressor or a cyclic process downstream.

Much like a water reservoir provides water during times of drought and stores water during the wet times, an air receiver tank compensates for peak demand and helps balance the supply of the compressor with the demand of the system.

Receiver tanks are required by law to have a pressure relief valve and a pressure gauge. The relief valve should be set 10% higher than the working pressure of the system.

It is also important to install either a manual or automatic drain on the receiver tank to remove water from the system. A coalescing filter and air dryer are best placed downstream of the receiver tank.