Bosch Rexroth Wins Hannover’s Hermes Award, Features Linear Drive

At the Hannover Messe trade show in Germany, Bosch Rexroth won the Hermes Award for its SVA R2 subsea valve actuator, the world’s first electrical actuator for controlling process valves underwater.

The Hermes Award is Hannover Messe’s annual international technology prize. It recognizes outstanding products and solutions that have a particularly high level of technological innovation.

According to a Hannover Messe press release, “the SVA R2 offers an energy-efficient and safe alternative to the actuators previously used in offshore oil and gas production. SVA are self-sufficient assemblies with their own fluid circuit and a variable-speed pump drive. The central unit and the kilometers of lines for the fluid are no longer required. This also greatly minimizes environmental risks. The SVA only require a power supply and a data line. A displacement control regulates the flow rate from the speed with almost no loss. This simplifies the construction and increases the energy efficiency significantly.”

All companies and institutions that exhibit at Hannover Messe are eligible to compete for the prize. It was awarded virtually this year at the Hannover Messe Digital Edition on April 12. From 2022 onward, the winner of the Hermes Award will again be honored at the Hannover Messe opening ceremony.

“With the SVA R2, the developers at Bosch Rexroth combine economic and ecological aspects into a sustainably innovative product for the maritime process industry,” jury chair Reimund Neugebauer, president of the Fraunhofer-Gesellschaft, said in the press release. “With the subsea valve actuator, existing electrical supply lines for sensors are sufficient for reliable operation of the actuators. The small dimensions and integrated interfaces provide industry with another advantage, because they enable the new actuator to be used and retrofitted in existing systems.”

Bosch Rexroth Displays Redesigned Linear Drive

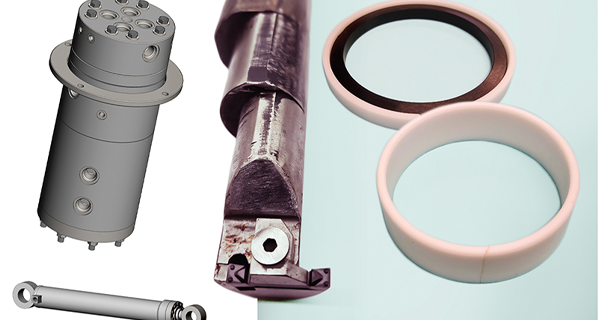

Also at Hannover this week, Bosch Rexroth featured its recently launched CytroForce linear servo-hydraulic axis.

The CytroForce concept squeezes previously bulky structures into a smart compact axis for power, movement, and positioning tasks. The out-of-the-box solution consisting of flow-optimized standard modules sets new benchmarks in terms of power density, energy efficiency, and quiet operations. It is supplied as a plug-and-produce system, meaning that even machine manufacturers who do not possess expertise in hydraulics can benefit from the optimized overall costs involved.

On account of their enhanced performance credentials, CytroForce axes, which are robustly designed to meet IP65 protection-class criteria, are redefining potential fields of application. Depending on the configuration in question, the CytroForce-M, which was the first to be launched, covers forces of up to 1,200 kN, distances of up to 1 m and speeds of up to 0.8 m/s. The positioning accuracy is 10 µm and the repetition accuracy is 5 µm.

In order to enable highly productive and economic presses, machine tools, and industry-specific applications, the CytroForce has been designed to ensure efficiency, availability, and usability at every junction of its life cycle: suitable product documentation is available up to the 2D or 3D CAD model. The axes are already preconfigured in the factory and, after mechanical installation, only need to be electrically connected.

The maintenance concept is also incredibly simple: with the help of a service kit, even nonspecialist service technicians can take fluid samples for laboratory analyses. Even the refilling process, which needs to be carried out from time to time, does not require any specific expertise. The service kits are available for all Bosch Rexroth servo-hydraulic axes, including CytroForce.

Condition monitoring and predictive analytics can also be conducted by combining the system with Rexroth’s ODiN service, helping to further increase the machine’s availability.

The modular CytroForce is based on the tried-and-tested variable-speed energy-on-demand drive Sytronix. In the case of CytroForce, a manifold and a differential or tandem cylinder are connected to this energy-efficient unit, consisting of servodrive and hydraulic fixed or variable displacement pump. All hydraulic components and interfaces have been flow-optimized with the latest cutting-edge processes. This reduces noise emissions and increases performance while minimizing dimensions.

Together with the tank, safety valves, and sensors, the CytroForce modules form a highly compact and efficient servo-hydraulic axis with a closed fluid circuit and an energy-on-demand and standardized drive and control concept.

For more information, visit www.boschrexroth-us.com.