Bosch Rexroth Valve Platform Offers Modular Control for Mobile Machines

From Bosch Rexroth

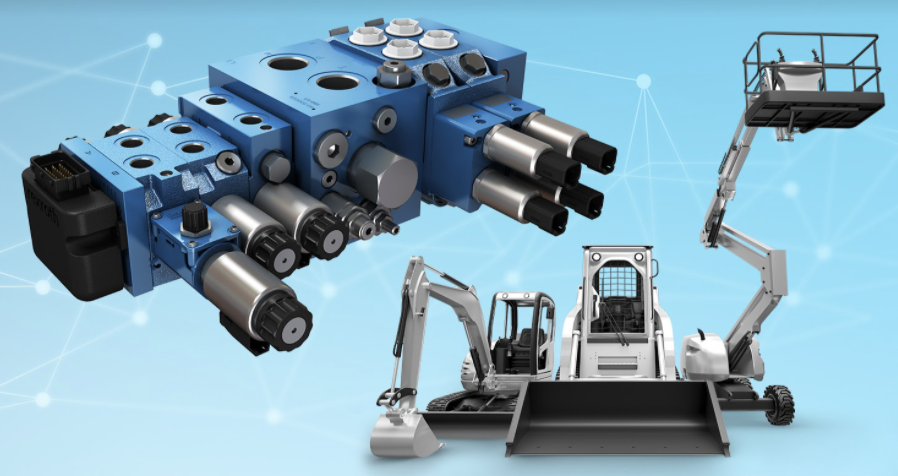

Flexible and adaptable, Bosch Rexroth’s Precompensated Valve Platform makes it easier for mobile-machine builders to selectively combine a range of hydraulic control valves into a single, integrated, multifunctional control solution to match specific operational and performance requirements.

The Precompensated Valve Platform combines multiple valves with minimal need for adapter plates or custom fittings. All the valves in the platform support precompensated load-sensing capabilities that ensure that the proper hydraulic flow is delivered to each function, independent of the overall loads on the hydraulic systems.

The platform incorporates load-sensing capabilities that improve efficiency, freeing more hydraulic power to the implement while enabling better machine designs. The load-sensing valves can also help reduce hydraulic cooling system size and costs, as well as potentially lower engine horsepower requirements.

In a load-sensing system, the control block of the valve senses how much flow needs to be delivered to individual cylinders on different parts of the machine as work is being done. It provides feedback to the pump so less energy is wasted to support all the machine’s functions.

In a crane, for example, functions include outriggers for leveling and stabilizing the machine, boom extensions and retractions, boom rotation, and so forth. For each function, the motor or pump speed and cylinder positioning can be precisely controlled over a wide range of conditions – simply and without the complex design challenges of adding external components.

The Precompensated Valve Platform incorporates three proven Rexroth load-sensing directional control valves:

- The compact EDG directional control valve, supporting flows up to 40 lpm (10.6 gpm) and up to 350 bar (5,076 psi) working pressure.

- The RM10 and RM15 load-sensing directional control valves, with flow rates of 90 and 150 lpm (24 and 40 gpm), respectively, and 280 bar (4,061 psi) pressure – a cost effective, compact, general purpose, multiapplication load-sensing directional control valve.

- The M4-12 control block, supporting up to 130 lpm (34 gpm) and 400 bar (5,801 psi) pressure for medium- and high-pressure applications ranging from forestry and agricultural equipment to construction equipment and incorporating a wide range of accessories, such as adjustable mechanical flow limiters and load-sensing pressure limiters on each port.

The Precompensated Valve Platform is a modular control concept: A single solution can mix multiple valves, scaled by flow and pressure requirements, and seamlessly combine basic valves with highly featured ones, providing a cost-effective plug-and-play valve platform that fits cleanly together, with minimal need for adapter plates or custom parts.

By combining multiple assemblies in one stack, the Precompensated Valve Platform can help reduce installation time and service costs, as well as related costs for hydraulic system assembly, plumbing, and fittings.

The platform is built around reliable, durable, field-tested Rexroth valve and control block families, proven to deliver long life cycles and high availability with minimal downtime for repairs.

For more information, visit www.boschrexroth-us.com/pcvp.

Mobile builders can also use Rexroth’s new CHoose compact hydraulics configuration tool to quickly configure the optimum Precompensated Valve Platform solution for their needs. The CHoose tool is a downloadable software that incorporates a full library of Rexroth compact hydraulics components with catalog information and provides a step-by-step process for selecting and configuring each valve component. For more information, visit boschrexroth.com/choose.