Bring It On: Digital Transformation in the ‘New Normal’

By Shaun Taylor, President, Global Machine Automation, Fluid Motion and Control, Europe, Middle East and Africa, at Emerson

Remote workforces, social distancing, reduced labor efficiency – these are just a few of the buzzwords surrounding the “new normal” manufacturers have faced since the global pandemic. Unfortunately, these are also some of the challenges layered on top of existing production pressures. For many operators, the onslaught of concerns surrounding new technologies, climate change, labor shortages, and operational efficiency is causing an examination of their day-to-day operations. In this intersection of challenges and pressures, the Industrial Internet of Things (IIoT) – and the digital transformation it enables – is poised to unleash an era of manufacturing that is more reliable, efficient, and sustainable than ever before.

Today’s real-world demands

Despite the maturity of the technology found in many manufacturing facilities, competitive pressures have increased in some new and very specific ways. Understanding these operational and profitability challenges is the first step to facing them – and in preparing for long-term sustainability.

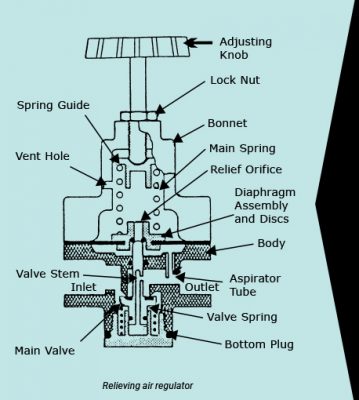

- Technology. Choices in hydraulics, pneumatics, and electric motion systems are met with a variety of connectivity and analytic options, all of which must be properly integrated and adopted if a manufacturer is to fully understand their operations.

- Sustainability. Helping customers reduce their carbon footprint and achieve their sustainability goals is no longer a luxury. Neither is running systems out of range, which uses excess energy and increases the likelihood of material waste.

- Workforce. While faced with an aging workforce and subsequent loss of experience, digital transformation solutions present a significant opportunity to capture the attention of a younger generation more comfortable with data and analytics.

- Safety. The COVID-19 pandemic has resulted in the need to reduce unnecessary foot traffic and the exposure of individuals to one another. Manufacturers are adapting to the new normal of social distancing, remote workforces, and other pandemic-response measures that have resulted in reduced labor efficiency. Digital transformation can help manufacturers adjust their manual and time-intensive work processes to be safer and more efficient.

- Overall equipment effectiveness. Maximizing productivity down to an individual machine level is necessary for understanding where efficiencies can be gained and costs can be reduced.

Leveraging IIoT

When properly leveraged, IIoT helps manufacturers connect islands of automation, unlock trapped machine data, and empower workers to deliver greater value. In a typical manufacturing facility, there may be dozens of machines that are involved in producing a finished product, and an inefficiency in one can create a cascading effect across the entire plant. By connecting individual machine “islands” and the data they individually provide, an operator can determine if one machine is running more efficiently than another and can spot potential issues before they become bigger problems. But connecting these islands of information isn’t just about data collection; it’s about extracting the most valuable insights and then piecing them together in ways that help operators make informed decisions. It’s also about starting with a scope that is both reasonable and understandable.

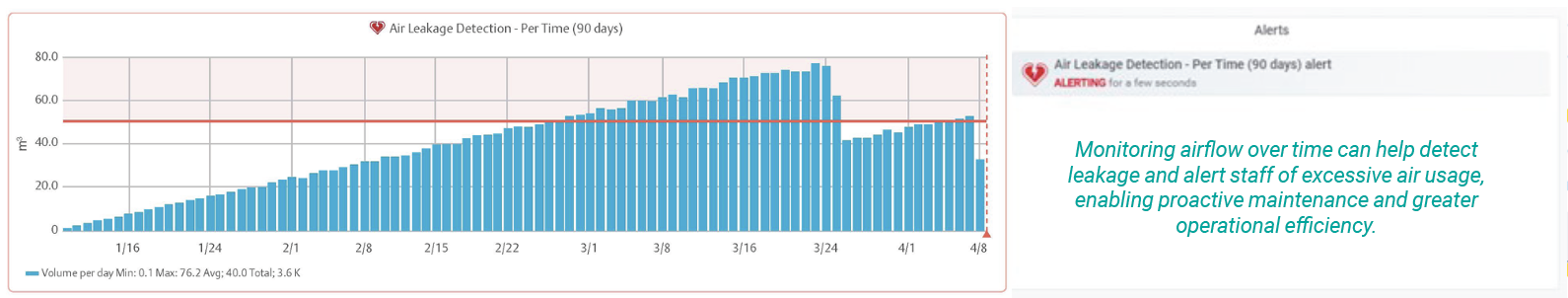

For example, in a manufacturing plant that relies on pneumatic operations, the benefits of IIoT are realized most effectively by monitoring air usage within systems, which can easily be accomplished on just a few machines. Using sensors like the AVENTICS Series AF2 to measure airflow, the system can identify the machine exhibiting the problem and send alerts directly to maintenance staff. By starting at this more individualized, machine level, operators can obtain actionable insights without the need for heavy data analysis and quickly realize a reduction in costs, improved production quality, increased throughput, and, in the case of pneumatic systems, improved sustainability.

Achieving results today

Information obtained through IIoT can disrupt the status quo and enable manufacturers to create future-ready operations with a quantifiable return on investment (ROI) they should start seeing in under 12 months. The key is to partner with the right device manufacturer to support the digital transformation and implement the appropriate solution.

- Scalability. By focusing on a specific problem or challenge, the initial project scope can be controlled and the results more easily quantified. At the same time, any solution should have the ability to scale for future needs and expectations; no one wants to add devices on top of existing devices. The ideal partner will be one who has a clear understanding of the long-term vision, not just individual devices, gateways, cloud services, or other singular systems.

- Flexibility. Together with scalability, device flexibility is critical. This is most easily realized by choosing devices that rely on open communication systems and architectures. The industry is evolving quickly, and being locked into a proprietary solution can prevent an operator from taking advantage of the latest technologies. In the fluid power and motion control sector, there is not yet a single, industry-wide set of IIoT standards, which is why it’s critical for any solution to be as open and flexible as possible.

- Portfolio. Leveraging technologies and solutions that use open IIoT protocols makes it easier to collect and share information. A manufacturer should look for edge devices that, in tandem with open protocols, can handle various technologies to help avoid unnecessary complexity in either operations or system architectures. The Emerson RXi2-LP industrial PC is one such device. Its vendor-agnostic PACEdge software runs nondeterministic applications to reduce latency and meet a variety of application-performance needs.

- Integration. Manufacturers should expect their device partners to assist with scoping a solution, including ROI estimates, device implementation, start-up commissioning, and long-term support.

- Insights. In the short term, most IIoT applications are focused on streamlining maintenance, increasing efficiency, and monitoring processes. But over time, the discussion shifts to become less about the devices and more about the insights they can deliver. What will be critical is how a device manufacturer can help an operator maximize its IIoT investment and unlock the data the device generates. Adding IIoT-powered intelligence will become accessible to more businesses, and not having actionable insights will become a competitive disadvantage.

As we face the simultaneous demands of a changing world and ongoing competitive pressures by rethinking old paradigms and leveraging the power of IIoT, operations can move forward with greater confidence and a renewed ability to meet both present and long-term needs.