Preventative Maintenance of Pressure Regulators

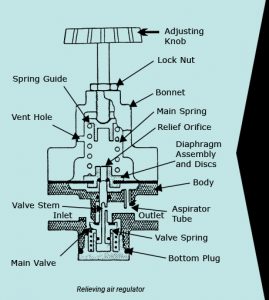

Air regulators keep the operating pressure (downstream pressure) approximately constant regardless of fluctuations in either the upstream pressure or the air consumption. Some regulators, known as relieving regulators, will exhaust/vent excess air, should the downstream pressure setting be lowered, or should it rise over the setpoint due to circuit action.

Air regulators keep the operating pressure (downstream pressure) approximately constant regardless of fluctuations in either the upstream pressure or the air consumption. Some regulators, known as relieving regulators, will exhaust/vent excess air, should the downstream pressure setting be lowered, or should it rise over the setpoint due to circuit action.

To regulate the air pressure of an air supply, the upstream pressure must be higher than the downstream pressure. The diaphragm or piston regulates pressure by opening and closing the main valve poppet. Outlet pressure acts on one side of the diaphragm, and the spring acts on the other. Spring force is adjusted by means of an adjusting screw to vary the pressure setting of the regulator.

To check a pressure regulator, release compression on the regulator spring by turning the adjusting knob counter-clockwise to open the outlet valve. Adjust the pressure regulator to approximately 80% of inlet pressure showing on the receiver side of the shut-off valve. The regulated air pressure will show on the regulator pressure gauge. Observe the regulator during operation to see whether the air regulator compensates for changes in flow while still maintaining the regulated pressure at 80% of inlet pressure.

Repeat the previous step at three other pressures: 20%, 40%, and 60% of supply pressure.

Finally, if you have a relieving regulator (and most pneumatic regulators are relieving), close the outlet valve to stop the flow of air from the regulator, and back off the regulator from 60% to 30% of the upstream pressure. This will test the regulator when over-pressure at the outlet is reduced to the new pressure setting by bleeding off air in the outlet passage through the vent holes to atmosphere. Note: If the pressure regulator is not equipped with vent holes, the regulator will not compensate without bleeding off air at the outlet manually.

WARNINGS

Relieving regulators are designed for non-combustible gas service.

Any device used for oxygen service must be properly cleaned for that service.

Non-venting regulators are designed for use with toxic, combustible, or oxygen-displacing gases.

TEST YOUR SKILLS

1. Air pressure regulators determine the maximum pressure:

a. At the compressor.

b. Downstream of the regulator.

c. In the receiver.

d. In the after cooler.

e. Upstream of the regulator.

2. In a system with sufficient upstream pressure, the pressure downstream of a properly sized regulator:

Will increase to receiver pressure when air is not being used.

Will decrease when air is not being used.

Is dependent upon the temperature of the air.

Should always be higher than the upstream pressure.

Should be approximately constant, regardless of the air flow rate through the regulator.

Could you help with a detail presentation slide of the operation, Preventative Maintenance as well as HSE consideration of Pressure Regulators in an Oil and Gas flow stations