Changing Hydraulic Filters: Timing Is Everything

By Emily Newton

By Emily Newton

Like any piece of equipment, hydraulic systems require regular maintenance to deliver peak performance across their life span. Anyone who works with these machines knows they should change hydraulic filters, but the ideal timing is often less clear. The industry is full of differing opinions and advice, making it difficult to know the correct information.

If you were to ask five people when the best time to change hydraulic filters is, you’d likely get five different answers. The most straightforward solution is to go by the manufacturer’s specifications, but many hold that these aren’t always ideal. Some say to replace filters according to a fixed schedule, and others suggest running equipment until performance starts to drop.

Here’s a closer look at the ideal time to replace your filters.

Deciding when to change a filter

First, it’s important to understand why your timing matters with these maintenance procedures. Fluid contamination is the number one cause of failure in hydraulic systems, so it’s crucial to keep systems as clean as possible. Waiting too long to change filters increases the chances that they’ll fail.

Contaminants clog the filter over time, eventually to the point where it affects fluid pressure. Systems may bypass the filter once this pressure reaches a critical point, allowing potentially contaminated fluid to pass through. Those without a bypass valve will encounter a similar problem when the filter itself collapses.

You’ll have to flush a hydraulic system that becomes contaminated, requiring extensive downtime. Contaminants could also damage components to the point of needing replacement or repair.

Similarly, replacing hydraulic filters too early or too frequently can also cause problems. While changing these components before necessary will ensure the system remains in prime condition, it causes unnecessary downtime. The costs from lost productivity could rival that of equipment failure.

An optimized maintenance schedule prevents both of these scenarios. You must avoid waiting too long to change filters while being sure not to do so too frequently.

There are several schools of thought about the best time to replace hydraulic filters. They have developed as experts have acquired new information about filtration and how different practices affect it. In many cases, choosing among these approaches comes down to a facility’s specific needs and resources, muddying the waters of which is best.

Since hydraulic systems are so varied, they come with different maintenance needs. What works for a new machine may not be ideal for an older, more worn-down one. Similarly, closed loop systems carry different maintenance considerations than open loop alternatives.

To determine which method is best for your system, you should understand the benefits and pitfalls of each.

Preventive vs. corrective maintenance

The first area in which you’ll find differing filter replacement practices is in preventive versus corrective maintenance. Corrective maintenance, also called reactive maintenance, is the most straightforward solution. It involves running equipment until issues show, then correcting them. While many operators follow this type of maintenance out of convenience, few would argue that it’s ideal.

On average, corrective maintenance for a hydraulic pump costs $18 per horsepower per year, more than any other method. These high costs come from the longer downtime and more extensive repairs needed. It may seem like waiting for a filter to fail before replacing it saves time, but the extended period it takes to repair it counteracts any savings.

Preventive maintenance, where you replace filters before they fail and cause further damage, is far more cost-effective. In addition to preventing costly breakdowns and unplanned downtime, it also keeps hydraulic systems in prime condition for longer. Since you prevent excess contaminant buildup, you maintain more consistent pressure, leading to more efficient operations.

Regardless of your specific situation, you should use a preventive approach to replacing hydraulic filters. This covers several different methods, though, and you should know which works best for you.

Following manufacturer guidelines

The first and most familiar way to embrace preventive maintenance is by following manufacturer guidelines. Your hydraulic system comes with recommended maintenance practices, like when to change its filters, providing a clear, straightforward answer to this question. Since the manufacturer is probably more familiar with the system than anyone else, they’ll better understand its unique needs.

More often than not, manufacturer recommendations for filter changes are based on hours of service. This provides a firm basis for developing a maintenance schedule, but it’s also where this method’s cracks start to show. Operational hours alone aren’t the only factors that can affect filter life, and they’re not always accurate.

Hydraulic filters accumulate debris at uneven rates, so contaminant levels are rarely uniform. If you’re using a mobile system in various conditions, contaminant levels are even more unpredictable. Consequently, what may be a safe time between replacements one time may be too long at another time.

Manufacturer specifications also assume you’re using the recommended filter type. Using a different filter for cost or efficiency reasons will result in different maintenance needs. So while manufacturer guidelines are helpful and won’t likely cause significant issues, it’s not the most accurate option.

Monitoring performance

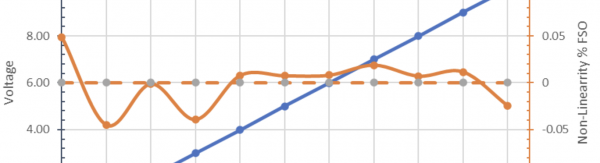

A more precise way to determine when to change hydraulic filters is to monitor system performance. Instead of going by a fixed schedule, users check levels such as fluid pressure to see if a filter is nearing the end of its life. This data-based approach ensures you replace filters when needed while avoiding downtime from unneeded maintenance.

A more tech-centric version of this approach called predictive maintenance has emerged in recent years. It feeds data from sensors into machine-learning algorithms to predict when you’ll need to replace filters. Studies show it can improve equipment uptime by as much as 20% while reducing maintenance-related costs by 10%.

Predicting when filters will fail lets you plan to replace them more easily than checking performance levels manually. The one downside to predictive maintenance is that it comes with higher upfront costs. Retrofitting equipment with the necessary sensors and buying or training a machine-learning algorithm is not a cheap endeavor.

You can predict when filters need replacement yourself, but it requires high expertise and is less reliable. Investing in predictive maintenance is the best option overall, and it will generate a positive ROI eventually. Given the high upfront costs, though, it’s best to apply it to just one or two systems at a time, then gradually expand.

Choosing the right filter

When you do change your hydraulic filters, you should also consider the type you’re using. Switching out the included or manufacturer-recommended filters for more efficient options can reduce future maintenance needs. However, using the wrong type can result in higher costs and less time between replacements.

Perhaps the most crucial consideration for filters is their beta (ß) ratio. This figure represents how many particles of a given size the filter can remove. A ß5=10 filter, for example, removes 10 particles of 5 microns or more for every one particle of that size that passes through. Most experts recommend using filters with a beta ratio of at least 75.

You can find filters with beta ratios in the thousands, but remember that higher efficiency comes with more dramatic drops in pressure. The higher the beta ratio, the more power you’ll need to compensate for this drop.

Remember that the air can carry contaminants, too, so you’ll need to replace breather filters as well. These don’t need as high of a beta ratio since filtering air is typically more efficient than fluids. If you work in a humid area, you may want a desiccant breather, which removes water.

Adding additional filtration

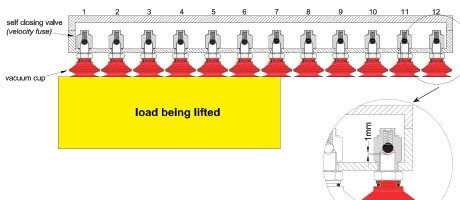

You may consider adding more filtration to your hydraulic system to prevent fluid contamination even further. Generally speaking, adding off-line, or kidney loop, filtration is a cost-effective way to reduce the wear cycle.

Off-line filtration doesn’t interfere with the hydraulic system’s operations, so you can add it without affecting performance. Using these systems on top of built-in filters also helps lessen the load of each one. Consequently, they can run for longer periods before needing a replacement, reducing maintenance costs and downtime.

Many off-line filtration systems allow you to turn them on or off on demand. This feature lets you preserve them longer, only using them in moments of high demand. These systems come with higher upfront costs, but they’ll pay for themselves over time.

Replacing hydraulic filters regularly is integral to keeping your system running in peak condition and avoiding costly breakdowns. Since there are so many factors involved, hard-set maintenance schedules are insufficient in determining when to replace filters. Instead, you should consider performance-based maintenance, ideally using predictive technologies.

Optimized filter replacement strategies can carry high upfront expenses, but they save money in the long run. If you invest in and transition to these systems early, you’ll prepare yourself for future rewards.

Emily Newton is editor-in-chief of Revolutionized, an online magazine discussing the technologies advancing the industrial sector. For more information, visit https://revolutionized.com/.