Compressed Air Systems: The Mathematics of Efficiency

By Ron Marshall

You may wonder why people say compressed air is the most expensive and inefficient utility in a facility. By doing some research and looking at simple ratios, it is easy to find out why.

Let’s consider an air tool that outputs one horsepower to a device connected to its shaft. If you look at the manufacturer’s specifications you might find that the tool will consume about 25 cfm of air at an output of one horsepower. Since a typical air-cooled screw compressor consumes about 20 kW for every 100 cfm, this 25 cfm will consume about 5 kW. This is the equivalent to range from 6 to 7 hp of air compressor capacity while running at 100 psi. This shows the conversion efficiency of the compressed air medium. The air compressor consumes about 6.5 times as much power than is delivered at the tool.

But the calculations don’t stop there. The conversion efficiency just discussed is for a perfect system, with compressors running at maximum efficiency, no leakage losses, and no pressure drop. This hardly represents real life; these are calculations done in a laboratory. In real life, conditions often get worse.

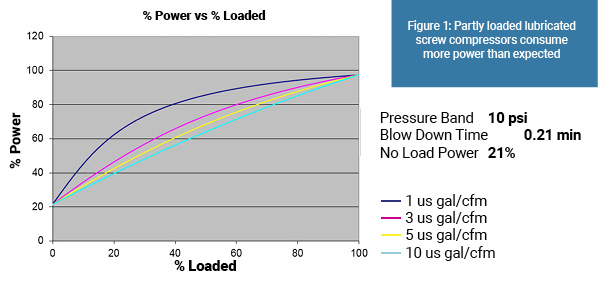

With regard to the compressor, if you are using a lubricated screw with small storage, the compressor will consume more power than expected when it is partly loaded. Let’s assume an average loading of 40%, we can see from Figure 1 that with a typical storage receiver size of one gallon per cfm compressor output, the compressor consumes 80% of its nameplate power while outputting only 40% of its air, twice its full load power ratio. This makes the conversion efficiency 13:1.

And regarding leaks, often a typical facility will have leakage rates from 20 to 30% of all the compressed air produced. For this example, let’s use 25%. This means you must make and pay for extra compressed air to feed the air tool, costing about 25% more power. The conversion ratio is now 16:1.

As pressure drops in the system, air dryers, filters, piping, connectors, and hoses adds up to a typical 20 psi pressure loss. With compressed air at about 100 psi, this extra pressure costs about 10% more than the original lossless system we originally considered. And the higher pressure causes the leakage in the system to consume about 18% more air. The conversion efficiency is now up to 18:1

What does all this mean? Instead of consuming from 6 to 7 hp to deliver one horsepower of power to the air tool, a typical system might actually cost from 18 to 20 hp to deliver one horsepower at the shaft of an air motor. This is why compressed air is called a costly utility.

What can be done to improve things? Here are a few tips:

- Consider using direct drive electric tools where ergonomics and safety allow. This is especially important for tools that run all the time, with many operating hours per day.

- Properly maintain your air tools. Internal wear causes internal leakages that can greatly increase the air consumption and decrease the power output. If your tool needs to be lubricated, make sure your personnel know how to do this.

- Choose more efficient air compressor types, if you must run a screw compressor, often the best choice is one that runs in start/stop duty or uses a variable speed drive to control the output. This gives much better conversion efficiency than a load/unload unit with small storage.

- Reduce pressure losses by properly sizing compressed air piping, oversizing filters, dryers, regulators, air fittings, hoses and connectors. After doing this, reduce the discharge pressure of the compressor to save power.

- Fix your leaks by maintaining a leakage detection and repair program in your facility. A properly maintained system will have leakage rates at under 10%. Fixing all the audible leaks will reduce most of this loss, but best practice is to use ultrasonic leakage detectors, some of which are available at low cost of less than $1,000. At 10 cents per kWh, the repair of 5 cfm of leaks on a system running full time will pay for a low cost ultrasonic unit in one year.

- Use airless condensate drains for your compressed air system rather than wasting valuable and expensive compressed air through excessive purge.

Ron Marshall is owner of Marshall Compressed Air Consulting, a company that specializes in compressed air efficiency assessments.

Visit www.compressedairaudit.com

Join the LinkedIn discussion group: Compressed Air Efficiency