Continental Announces New X-Life XCP5 Premium Flexible Braided Hose for Hydraulic Industry

- X-LifeTM XCP5 offers 5000 PSI working pressure, which is higher than traditional braided hoses.

- New high-pressure hose is part of the company’s initiative to offer a premium braided hose portfolio that is ISO 18752 AC compliant.

- Announcement demonstrates Continental’s commitment to becoming the innovation leader and full-range supplier of hydraulic hoses.

Fairlawn, Ohio, December 3, 2024.

Continental today announced the X-LifeTM XCP5 hose, a new flexible braided hose for high-pressure hydraulic applications requiring extra abrasion resistance. The hose is part of the company’s initiative to offer a premium braided hose portfolio that is also ISO 18752 compliant.

The new X-Life XCP5 is designed as a premium hose with braided construction for high-pressure applications and further demonstrates Continental’s commitment to becoming the innovation leader and full-range supplier of hydraulic hoses.

The X-Life XCP5 hose is best for applications that require tight bends and flexibility, including in the agriculture, mining, manufacturing, construction, and energy industries. It works in temperatures ranging from -40 to 212 degrees Fahrenheit.

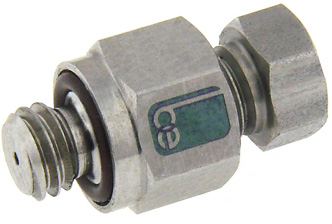

The fittings can be ordered with an optional ArmorPlate coating shield, which provides protection from the harshest elements. The coating provides extreme corrosion resistance – almost seven times more than the SAE J516 requirement of 144 hours – and delivers 1,000 hours of red rust corrosion resistance.

Continental’s B2 fittings are constructed from a single piece of steel without brazed or welded joints to provide ultimate protection against leaks and potential leak paths. Interlocking bite-to-wire technology delivers maximum coupling retention for safer assembly and reliability.

The X-Life XCP5 is currently available in three sizes: 1/2”, 3/8” and 3/4” inch. It can be crimped with Continental’s one-piece B2 type fittings.

In addition to new products, Continental also announced this year the construction of a new, $90 million manufacturing plant focused on the production of hydraulic hoses in Aguascalientes, Mexico. The new plant will enable the company to double its hydraulic hose manufacturing capacity and is designed to help meet demand from current and new customers in multiple industries across North and South America.