Cool Applications Need Cool Filters

By Eric M. Rud, Global Product Manager, Filtration Division, Eaton

Lubricating oil must deliver effective wear protection for compressors in food and beverage plants, cold storage facilities, chemical mills, and ice arenas.

Proper lubrication of refrigeration compressors is critical, making effective filtration vital to smooth-running systems. The lubricating oil must deliver effective wear protection for reciprocating, vane, and screw compressors in industrial refrigeration systems. These systems are commonly found in food and beverage plants, cold storage facilities, chemical mills, and ice arenas.

Particles in the lubricant increase compressor wear and reduce the life of mechanical components. Excellent filtration systems are therefore necessary to maximize compressor life and prevent costly downtime. Oil degeneration or aging causes the buildup of damaging compounds leading to premature wear of moving parts. This reduces compressor efficiency and reliability, resulting in higher energy and maintenance costs.

The life of a lubricant is not easy

Many circulating oils developed for industrial refrigeration compressors are designed to operate in ammonia refrigeration systems. Ammonia refrigeration compressors tend to be highly efficient and reliable with proper care. The oil must be able to lubricate surfaces under demanding conditions without carrying the ammonia with it or permitting wear.

There are two main types of filters in refrigeration compressor lube systems. The first provides particulate screening in the oil; the second separates ammonia from the oil. To ensure maximum efficiency, the amount of ammonia that dissolves in the oil must be minimized.

It is imperative to consider the quality of the filtration solution as commercial refrigeration applications face different challenges compared to standard industrial filtration needs. The element must filter oil slightly contaminated with refrigerant. The filter housing meanwhile must be durable for the often-demanding conditions of the environment in which it is installed.

Filter efficiency is expressed as a beta ratio (ẞ) produced by the multipass filter performance test (ISO 16889). Results are reported as a ratio comparing the number of particles greater than a designated size (ẞx) upstream versus downstream of the filter during testing.

When selecting a filter for use in a refrigeration compressor lubrication system, a minimum beta ratio of ẞx>= 200 (99.5% of contaminant particles size “x” or larger are filtered) should be selected. Filter fineness recommendations vary by compressor manufacturer but generally fall within the 3µm to 10µm range.

Also critical is the dirt-holding capacity, pressure drop characteristics (delta p) and beta stability of the filter. Beta stability is the ability of a filter element to perform well in a dynamic refrigeration compressor system and not simply in a laboratory.

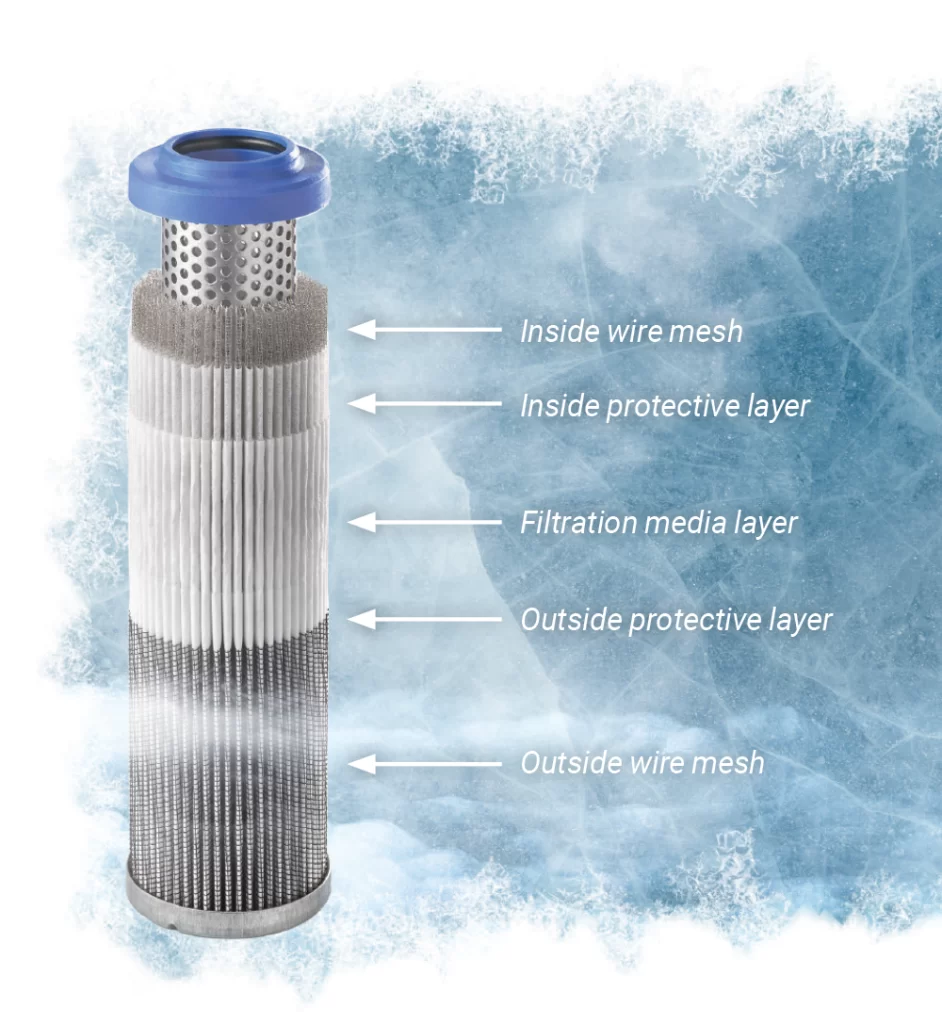

Today’s most innovative filter elements use multiple layers of synthetic media to maximize performance in all areas. Each filter layer provides a certain function that supports filtration performance, dirt-holding capacity, or beta stability.

Filters for cooling applications

Eaton has developed a standard approach to industrial compressor filtration using special NH3-resistant filter elements protected by carbon steel or stainless steel housings. These filter elements are specifically designed for compressors working with oil and ammonia mixtures (the most used refrigerant) or with other common refrigerants (typically CO2, N2 or halogenated hydrocarbons).

The combination of high-integrity pressure containment vessels and NH3-resistant filter elements effectively cleans lubricating oils and guards against the ingress of environmental contaminants. These filter elements are specifically suitable because they are resistant to ammonia that is often contained in compressor lubricating oils (NH3 up to 10% gases). These filters are equipped with ammonia-resistant support fleece and adhesives that withstand a maximum temperature of 194°F (90°C) to help ensure refrigerant compressors can continue to operate reliably.

The combination of industrial pressure filters and special NH3-resistant filter elements helps to ensure oil integrity and protects downstream components from contamination levels per the recommended cleanliness target. Most low-pressure filter arrangements (simplex or duplex) are suitable for working pressures up to 913 psi (63 bar). Associated filter elements having different filter materials, construction types and micron ratings to meet changing requirements are also widely available.

A closer look at these special filter elements shows they are designed with synthetic glass fiber fleece media that is shielded on both sides with a protective layer and steel wire mesh. To increase surface area and increase the resistance to pressure and flow fluctuations, the media is pleated. Notable is that these filter elements require the use of special adhesives that are also resistant to ammonia.

An often-overlooked aspect of dirt-holding capacity and element service life is the effect of the surface area. An element with twice the surface area might be expected to last twice as long. In actuality, the extended life is often 2.5 to 3.5 times longer. This is because the reduced flow density through the media allows for more effective contamination capture.

So why not specify elements much larger than needed to increase the service life? This comes down to right-sizing the filtration system to maximize the cost benefit. Larger elements cost more and likewise require larger and more expensive filter housings. That is why it is important to work with a reputable supplier to assist in specifying the appropriate media types, sizes and design standards such as API 614.

A well thought and consistently applied filtration strategy built around modern systems using special materials can improve refrigeration compressor efficiency and availability. It can also extend the life of lubricating oils. Overlooking the need for fine filtration will lead to damaging effects and can ultimately impact profits when problematic systems must be taken offline.

The market offers many simplex and duplex filter arrangements for refrigeration compressors designed according to industry certifications. These include EN13445, AD2000, ASME Sec. VIII, Div. 1 and PED requirements for CE marking, where applicable. It is critical to ensure that all systems and components comply with the applicable standards. The more specific the application, the more complex the acceptance requirements. Providers should not only supply high-performance filtration solutions but also the necessary certificates for food and beverage, cold storage, chemical, and other markets in which refrigeration compressors are found.

Also consider that a component can only work well if it harmonizes with the overall system. Solution providers should rely on extensive know-how in the plant and all the specifics of the operating environment when developing filtration systems. Proper filtration of refrigeration compressor lubricant oil can be complex and typically benefits from a build-to-order or engineer-to-order approach, with all solutions being designed and tested according to the customer’s exact requirements.

In individual cases, expert consulting services help ensure that new refrigerator compressor systems are equipped with the correct filter system right from the start. Product design and inspection specifications, such as those in an individual inspection and test plan, should take place together with the customer to ensure that all requirements are met. In accordance with the performance requirements and process parameters for each application, the optimum filtration protection solution can be achieved. In other cases, a detailed fluid analysis can be performed on-site or in a laboratory to determine the best filter element for the lubrication system requirements.

In individual cases, expert consulting services help ensure that new refrigerator compressor systems are equipped with the correct filter system right from the start. Product design and inspection specifications, such as those in an individual inspection and test plan, should take place together with the customer to ensure that all requirements are met. In accordance with the performance requirements and process parameters for each application, the optimum filtration protection solution can be achieved. In other cases, a detailed fluid analysis can be performed on-site or in a laboratory to determine the best filter element for the lubrication system requirements.

Where refrigeration compressor systems are found, a special filtration process can help to cut operational costs and improve uptime for critical assets. There are many ways that cool filters can benefit cool applications. A conversation with a knowledgeable expert or supplier about the specific needs of your facility is the best place to start. •