Cost-Reducing Modern Pneumatics

By Linda Caron, CMSE®, Certified Machinery Safety Expert (TÜV Nord), Global Product Manager, Factory Automation, Parker Hannifin Corporation, Pneumatic Division

As modern pneumatic components become more complex, knowing what to look for in plant becomes more critical. Identifying cost savings and issues that can be remedied before they become major system issues can save thousands of dollars in unplanned downtime and rebuild.

Effective pneumatic systems need properly sized, installed, and maintained components from compressors to work stations. A few wrong choices, however, can lead to everything from wasted energy to system failures. Consider the following steps when looking to maximize the performance of your company’s all-important pneumatic components.

Establish a Preventive Maintenance Program

Extending the life of a vehicle requires regular maintenance and oil changes. Pneumatics is no different. Compressed air is dirty and must be treated properly. Every system requires some form of ongoing maintenance. This will ensure lubricators are not left to run dry, filters are cleaned and contaminants are removed from rust, metal shavings, water, and unwanted oils. Many oils used in compressors are not suitable for the sealing system in pneumatic components. Yellow filter elements could be a sign that there is a problem in your compressed air system from compressor oils. Finally, if you hear a hiss you have a leak and this quick, easy fix will save you money.

Predictive Maintenance

This buzz word is all about avoiding a components failure and being proactive to maintenance rather than reactive. Get some help in this area with sensors. It’s better to know your car is low on tire pressure than the surprise of a flat. A flow sensor that fits in line with an FRL unit, or is installed at a work piece, can identify blocked filters that would otherwise go unnoticed. Blocked filters restrict air supply, allow contaminants to build, generate additional heat and eventually degrade a system to the point of failure. Sensors are available for almost every component in the plant. Continuous position sensors can be used on cylinders to determine the function of the cylinder and show over time if heat or wear is generated.

This buzz word is all about avoiding a components failure and being proactive to maintenance rather than reactive. Get some help in this area with sensors. It’s better to know your car is low on tire pressure than the surprise of a flat. A flow sensor that fits in line with an FRL unit, or is installed at a work piece, can identify blocked filters that would otherwise go unnoticed. Blocked filters restrict air supply, allow contaminants to build, generate additional heat and eventually degrade a system to the point of failure. Sensors are available for almost every component in the plant. Continuous position sensors can be used on cylinders to determine the function of the cylinder and show over time if heat or wear is generated.

Save Energy

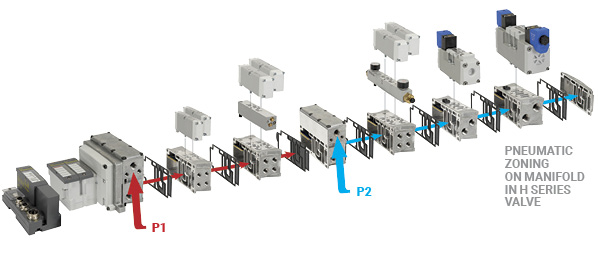

Right sizing equipment is critical in the specification process. Don’t buy what you don’t need. Oversizing costs money and waste’s valuable energy. Use pneumatic zoning on a manifold to mix pressures, to add vacuum to the application or to manage the use of supply pressure. Pressure boosters are another valuable alternative to oversizing the flow from a compressor to the largest workpiece. Simple steps can also be taken such as locking your regulators. This prevents workers from adjusting a systems overall pressure in a bid to get more air to individual workstations. Opening a regulator to increase flow can damage a sealing system, waste energy, or even cause physical harm.

Safety on Machine

Safety costs money but work place injuries cost more. Thirteen people die every day in the US due to industrial accidents. Consider areas on a machine where you can be trapped or entangled or injured. Look at the value of a risk assessment. If you can’t design out risk you must look at light curtains, interlocks, machine guarding or safety exhaust products to block or prevent hazards. Call in OSHA for help if you don’t know where to start. They are willing to work with you to get your plant up to safe standards.

Safety costs money but work place injuries cost more. Thirteen people die every day in the US due to industrial accidents. Consider areas on a machine where you can be trapped or entangled or injured. Look at the value of a risk assessment. If you can’t design out risk you must look at light curtains, interlocks, machine guarding or safety exhaust products to block or prevent hazards. Call in OSHA for help if you don’t know where to start. They are willing to work with you to get your plant up to safe standards.

Consider Changing your System

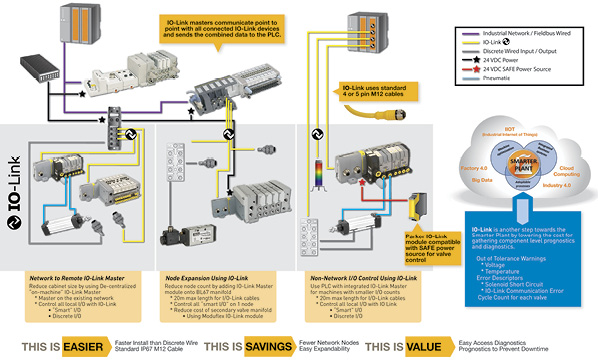

The world is migrating to low cost EtherNet based plant floor connectivity. Many companies still use hardwired solutions. Consider looking at networked based connectivity and switching from trunks of wire to a simple EtherNet port. IO-Link is another opportunity to save because you can run field level devices back to the IO-Link master which saves in time, wiring, component cost and troubleshooting. Todays advanced network nodes come with many advantages such as prognostic data for predictive maintenance, built in sensors for shorts, over current, cycle counting, thermal management…. The list goes on.

Click image to enlarge

Choose & Maintain your Filters Wisely

A standard known as DIN ISO 8573-1 governs the filtration levels required for a system. This identifies the solids, water and oil that should be separated out of a well-functioning system. Required levels of filtration are defined down to the micrometer. This standard was recently updated, so ensure you are still in compliance.

Cleaning the intake filters at the compressor sounds simple: Remove the compressors filter and clean it. But the related procedures can vary, depending on whether the system relies on a reciprocating, rotary screw or rotary centrifugal compressor. Maintenance manuals can offer some important guidance.