Danfoss Launches Thorx Motor, Service Passes

Danfoss Power Solutions, a supplier of mobile and industrial hydraulics as well as electric powertrain systems, recently announced two new product developments: its Thorx family of cam lobe motors and remote service passes for its PLUS+1 CS10 wireless gateway.

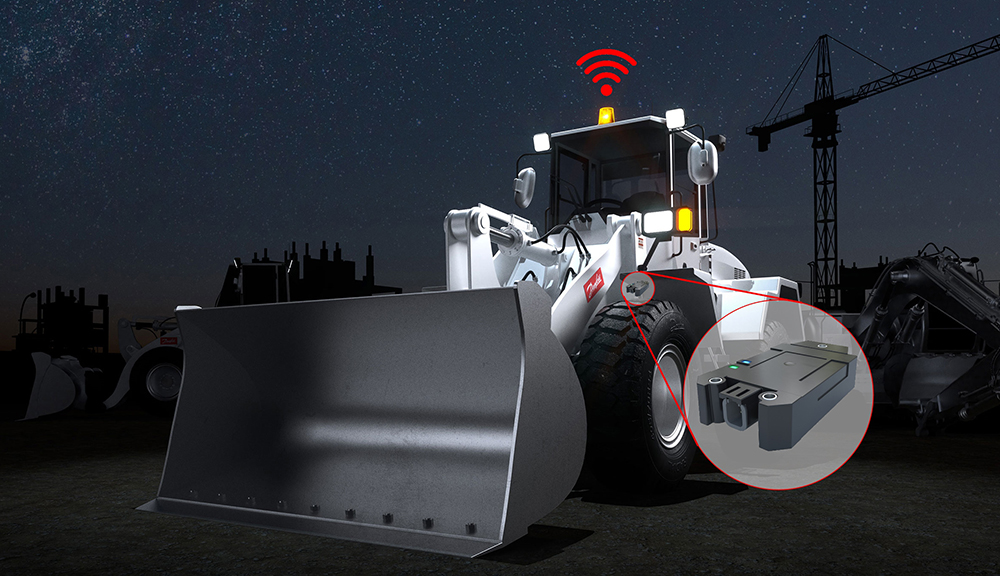

Remote service passes

Remote service passes allow machine technicians to connect remotely to a machine with a CS10 device installed to monitor machine behavior, debug, and update firmware over the air. This reduces machine downtime and eliminates technician travel costs, resulting in high savings potential.

CS10 remote service passes enable technicians to monitor changes in equipment or operation and set alert triggers to notify stakeholders when a change is detected. The passes also enable debugging. Technicians can access the machine’s CAN data bus over a remote connection to diagnose issues. Another capability is faster machine prototyping. Original equipment manufacturers can get a machine into the field sooner with the ability to remotely update firmware and software configurations.

Remote service passes work with Danfoss’ entry-level CS10 wireless gateway. With these passes, it is now possible to get a global connection by connecting the CS10 device to the internet through a local Wi-Fi hotspot. A single pass lasts for 24 hours and provides unlimited data for virtual service sessions from anywhere in the world using the company’s PLUS+1 service tool. The pay-per-use model offers flexibility, enabling companies to use a digital service plan as needed rather than pay for a monthly data plan.

The CS10 gateway and remote service passes are part of Danfoss’ PLUS+1 Connect ecosystem, which combines telematics hardware, software infrastructure, and user-friendly interfaces. In addition to the CS10 gateway, Danfoss offers the CS100 and CS500 devices, which offer cellular connectivity. Customizable and scalable, PLUS+1 Connect provides the insights for fleet managers, system integrators, and OEMs to reduce machine downtime, increase efficiency, improve performance, and optimize system design.

To learn more, click here.

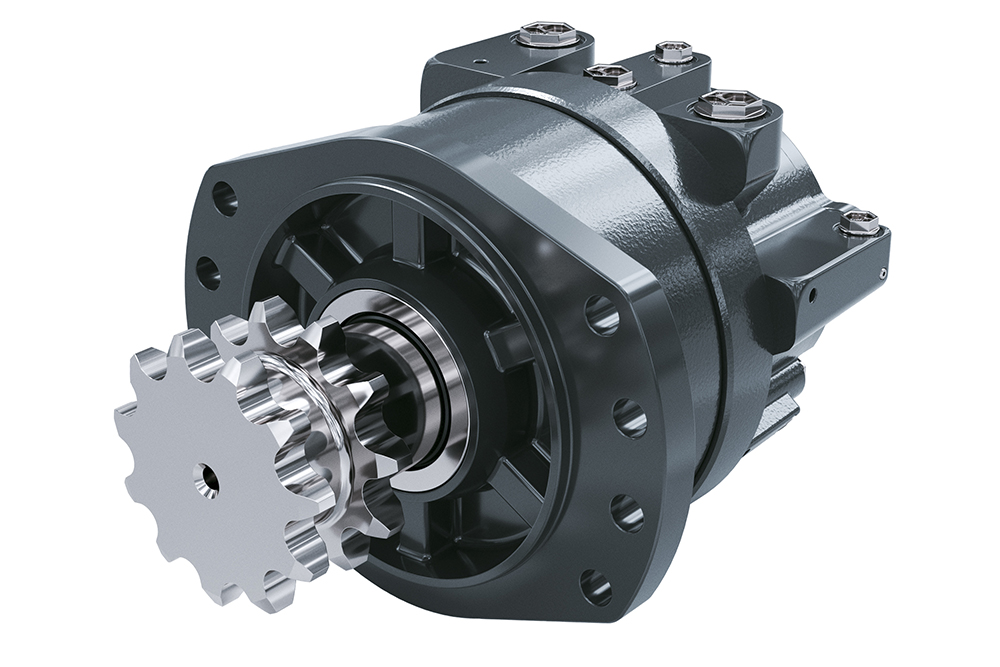

Thorx cam lobe motors

Danfoss recently launched its Thorx family of cam lobe motors. The first product, the CLM 8 S motor, is now available. Designed for construction machinery with chain drives, such as skid steer loaders, the compact motor offers better performance, higher efficiency, and longer lifetime than other cam lobe motors.

The Thorx motor features newly developed two-speed technology, which offers 70% shock reduction when shifting speeds compared to other cam lobe motors. The technology delivers smoother speed changeover with a consistent, quick response time, even at low temperatures, resulting in superior machine handling and better operator comfort. The motor also produces less noise when shifting, further improving comfort.

Compact construction is another considerable advantage of the Thorx CLM 8 S motor. By integrating the parking brake rather than bolting it to the rear, the motor is 33% shorter in length than similar products, creating the most compact drive solution in its class. The smaller size results in easier integration and assembly while enabling the use of larger, longer-lasting chains.

The integral parking brake is the toughest on the market, offering a longer service life. Thorx motors utilize a proven brake design that has been optimized to withstand 100 dynamic emergency stops throughout a machine’s lifetime, which is 20 to 25 times more than competitive cam lobe motors.

The Thorx CLM 8 S motor offers 5% higher efficiency than other cam lobe motors, with better starting efficiency and performance at low rotations per minute, plus improved mechanical efficiency at high speed. Operators can achieve faster travel speeds or use less power at the same speed while wasting less energy in the form of excess heat.

For more information, click here.