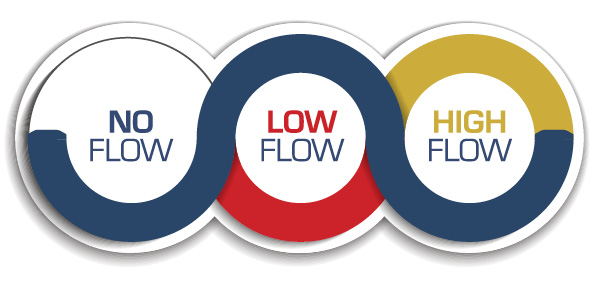

Determine the Cause of No Flow, Low Flow, High Flow

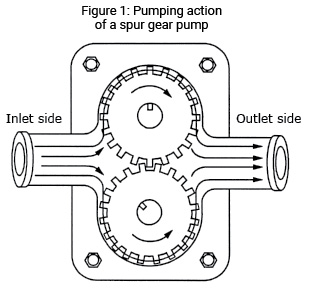

Positive displacement pumps deliver flow because the fluid is physically displaced by the pumping chamber from the inlet of the pump to the outlet of the pump. Figure 1 illustrates the pumping action of a gear pump as gear action divides flow at the inlet and transports fluid in the teeth around the outside of the gears as they turn. The fluid from each gear joins at the outlet and exits the pump. The amount of fluid the pump will deliver is approximately the same for each revolution of the input shaft, regardless of output pressure, and while slippage past the close fitting parts varies, actual measured delivery will be within 5 to 10% of the specified volume if the pump is in good condition.

If a fixed displacement pump operating at rated rpm will not deliver flow at the outlet, there is something wrong with the pump. This assumes the inlet receives fluid and is not obstructed or open to atmosphere, and that the drive gear, which is commonly keyed on the input shaft, has not sheared. What this means is that the pumping chamber cannot be sealed and back pressure against a load causes the pump to simply churn the fluid inside the case.

If a fixed displacement pump operating at rated rpm will not deliver flow at the outlet, there is something wrong with the pump. This assumes the inlet receives fluid and is not obstructed or open to atmosphere, and that the drive gear, which is commonly keyed on the input shaft, has not sheared. What this means is that the pumping chamber cannot be sealed and back pressure against a load causes the pump to simply churn the fluid inside the case.

The same symptom on a variable displacement vane or piston pump could be caused by a faulty pump compensator, or one that has been incorrectly set to a pressure below the requirements of the load, but if the compensator is functioning properly, the problem is the same. The pumping chamber is not sealing.

Occasionally, a pump will deliver more than rated flow. the most likely reason for this could be the pump is operating at higher than rated speed. A second but less obvious reason could be the pump has been replaced with a pump that has a larger displacement. before deciding that a pump delivers more than rated output, re-check the specification for rated gpm, and then check pump operating rpm. if the pump still delivers more than rated flow at rated pressure, consult with the supplier to determine if the pump was oversized in the manufacturing process.

“Low flow” from the pump causes slow cycle rates. This means that cylinders under load extend and retract slower than cycle times given for the machine by the manufacturer. The cause of “no flow” from a pump is relatively easy to find because something is definitely wrong. The problem of “low flow” from the pump is a more difficult problem to isolate, because it is a matter of establishing how much slippage through the pump can be tolerated. That is, how much flow must be lost before the flow is considered to be “low flow,” and the pump must be changed out? Some mechanics report that if a pump will deliver 70% of rated volume at load pressure, the pump is still considered to be usable. This would be “low flow,” however, when compared to manufacturer specifications. So in many cases, changing the pump because of “low flow” is a judgment call. In these cases, manufacturer recommendations should be followed.

The standard test for pump “low flow” checks the flow rate in 500 psi increments from 0 psi to relief valve psi at rated pump rpm. This is done by connecting a combination flow meter, pressure gauge, and temperature gauge at the pump outlet. A restrictor valve downstream of the flow meter is used to create back pressure against the pump. A good pump will deliver rated flow throughout the pressure range, whereas a worn pump may deliver rated flow when the system is cold at pressures below 1000 psi, but as the fluid warms up and thins out, the flow will drop off as the pressure is increased. To make a valid judgement about the condition of the pump, and whether it should be replaced, the fluid must be at operating temperature.

Be sure the pressure compensator on a variable displacement pump keeps the pump stroked to provide full delivery within the operating pressure range. A weak compensator spring, for example, could allow the pump to de-stroke and reduce pump flow at a lower pressure, which would invalidate flow meter readings as pump pressure is increased by the restrictor valve.

Test Your Skills

1. Which one of the following could cause “no flow” from a good variable displacement hydraulic pump?

a. Low operating rpm

b. Bypassing actuator

c. Leaking relief valve

d. High operating temperature

e. Incorrect pump compensator setting

2. Which one of the following would not be monitored during a hydraulic pump flow test?

a. Flow rate

b. Operating rpm

c. Test pressures

d. Fluid temperature

e. Pump displacement

3. When pressure testing a fixed displacement pump that is not defective, what might be expected to happen as the outlet is restricted?

a. Pump will cavitate

b. Pump flow will increase

c. Pump flow will decrease significantly

d. Pump pressure will decrease

e. Pump pressure will increase