Determining the Cause of Excessive Vibration

Elements of graphic furnished by Adobe Stock | Janisphoto

Vibration is often caused by a rotating shaft member. For example: bent drive shafts, out of phase drive shafts, off-center pump couplings, loose components including hose and tubing, and even an internal pump part such as a missing vane in a vane pump.

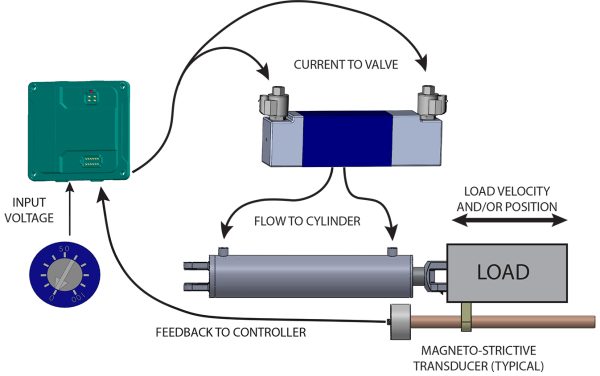

A typical truck mounted mobile pump mounting is shown in Figure 42 (Page 106). Remember that the drive shaft has a U-joint at each end, that the angle of the two U-joints is the same because the shafts are parallel, that the U-joints are off-set slightly to promote bearing lubrication, and that the yokes are in alignment so that the U-joints will be in phase.

Locating the source of the vibration can be difficult. A vibrating pump driven by an auxiliary drive shaft from the engine or transmission that is found to be vibrating may be loose. One might reasonably expect that simply tightening the mounting bolts would fix the problem when, in fact, it might not. The pump itself may be vibrating, the drive shaft may be bent, U-joint angles may be too great for the application, the speed could be too high, and the drive shaft could be assembled out of phase. When the job returns with the bolts loose a second time, the temptation is to use larger bolts in the belief that the pump is the vibrating member, and that the original bolts were simply too small for the application. If the source of the vibration is not found, it is likely that strengthening mounting members and bolt attachments will only delay failure of the pump, or whichever rotating member is the weakest. A better approach is to try to isolate the source of the vibration by testing each rotating member individually to determine the cause of the problem. This is not always easy. First, try using a stethoscope on various parts to determine which one seems to be the source of noise. Seeking expert opinion from the manufacturer should be part of the strategy. If a test bench is available, the system can be run on a bench. Finally, switching parts, such as a drive shaft, from one machine to another also may be required to duplicate operating conditions that cause the problem to occur.

Test Your Skills

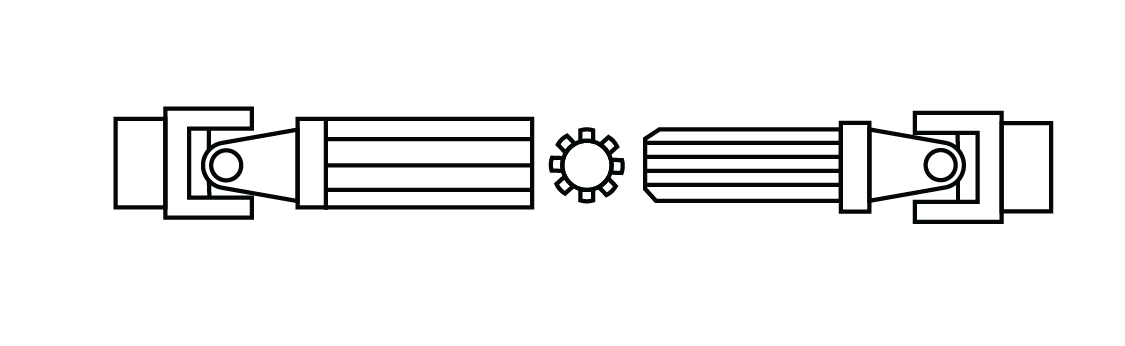

Figure 72. Figure for Review 50.1.

1 In how many positions can a balanced drive shaft slip joint with eight splines that connects two U-joints be assembled correctly?

A. 1

B. 2

C. 4

D. 6

E. 8