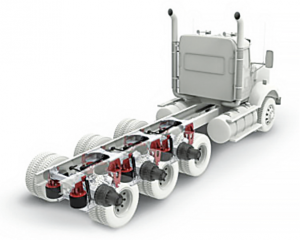

Driving for Safety in a Truck Suspension

By Valerie Chhokar, Marketing Manager, Lynch Fluid Controls

Buying a vehicle is a significant purchase. Consumers want to be sure the manufacturer has tested its safety and reliability. But few consumers would think about the equipment that tests the vehicle’s components.

Buying a vehicle is a significant purchase. Consumers want to be sure the manufacturer has tested its safety and reliability. But few consumers would think about the equipment that tests the vehicle’s components.

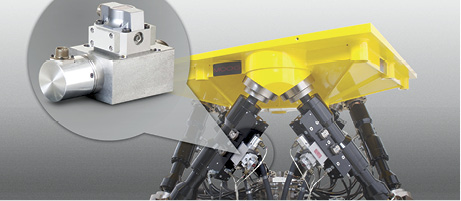

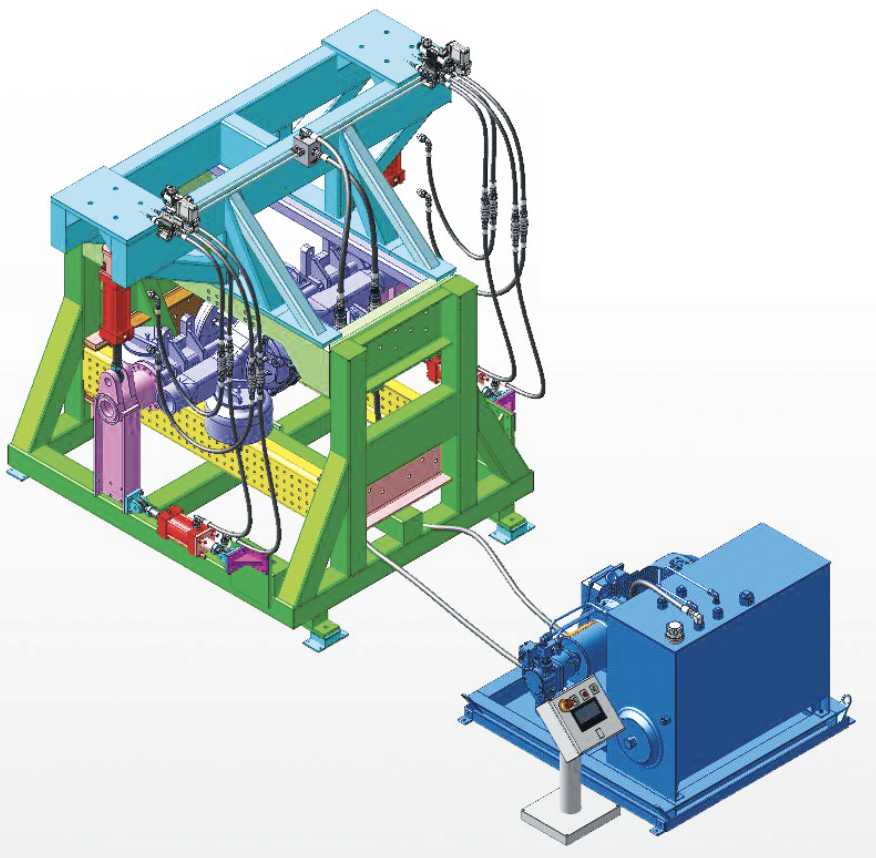

Lynch Fluid Controls worked alongside a well-known truck-suspension designer to build a device for testing and validating new truck-suspension designs. The machine simulates road conditions that would stress a truck suspension as it travels from uneven roads to smooth expressways with high breaking and acceleration side loads.

The project took on a variety of elements beyond strictly hydraulics. The unit has a customized PLC with GUI operating system for ease of set up and control. The operator can input test parameters, specifying amplitude, frequency, and loading condition for the two main cylinders. During set up the operator can manually jog the system to check the settings and parameters on the PLC.

The hydraulics involved in this unit includes four cylinders – two closed loop hydraulic cylinders that control the full range of motion and two additional cylinders for side loading. The two side-loading cylinders are manually set for side-loading conditions at the beginning of each test. Hydraulics was mandatory in the design of this unit due to the range of force necessary to conduct the testing (over 20,000 pounds loading per cylinder) and the cyclical frequency (up to 10 Hz).

Other components required to complete the unit included a Kawasaki pump capable of 20 gpm (76 lpm) and system pressures up to 3,000 psi (207 bar), which supplied the control system; two 3¼-inch (9.5-cm) bore cylinders with 9-inch (23-cm) stroke and linear position sensor feedback, each controlled by an ATOS proportional valve; and a Delta motion controller. These provide full-stroke cyclical control in both symmetrical and asymmetrical sinusoidal loading at speeds from 4 inches (10 cm) per second, and up to 10 Hz for very low amplitude frequency. Two additional 4-inch (10-cm) stroke cylinders provide up to 10,000 pounds (4,536 kg)

side loading.

For the electronic components of this device, two ATOS proportional valves with on board electronics were connected to a Delta motion controller. This simplified the valve to electronic integration and closed the loop on the cylinder position feedback. A control panel and PLC with a customized operator GUI completes the system.

The final product came together using 3D CAD files to expedite the system assembly and eliminate fit issues. Lynch’s engineering team was involved every step of the way to guarantee that the OEM’s frames, customized hydraulics, and the variety of other component were seamlessly integrated into the final product. The end result was a simple design that kept the test equipment cost effective with the capability to interface into an existing data acquisition system.

So when consumers are in the market for a new car or truck, they can be assured of the machinery that goes into developing a safe, reliable vehicle – even if they don’t think about it.