Fluorescents Shine a Light on Leaky Hydraulic Systems

From Spectronics Corporation

Every year excessive volumes of hydraulic fluid are lost due to leaks, resulting in equipment downtime, contamination, energy efficiencies, and cost overruns. Fluid power equipment cannot operate efficiently if fluid levels are low and not meeting manufacturers’ specifications. If leaks continue, equipment is at risk of mechanical failure, which ultimately leads to costly downtime repairs, production losses, and possibly fines. Incorporating leak detection into preventative maintenance can aid in limiting these and other issues associated with leaks.

Types of leaks

There are two types of leaks that can occur in hydraulic fluid systems: internal and external. Internal leaks occur within the hydraulic system and pose a serious problem to the machinery’s internal workings. External leaks are the most obvious, due to their visible nature. While leaks may seem insignificant, they lead to more operational problems in the long run. It is important to track them down as quickly as possible.

Internal leaks. Internal leaks can be caused by various problems, including wear and tear of component surfaces, poorly designed systems, incorrect initial installation, or using the wrong parts during repairs. All of these negatively impact system performance.

When internal leaks occur, they typically form narrow pathways or small cavities that allow hydraulic fluid to flow more freely. For example, as the surface of certain components begins to deteriorate, it adds volumetric space for fluid to pass by the components, allowing for more contamination to flow through and causing higher internal leakage rates.

An easy detection tool for this type of leak is a flow meter, which can be installed at various locations throughout the system to narrow down potential leak locations. Temperature measurement and ultrasonic detection are additional tools for detecting internal leaks. A knowledgeable technician can help determine which detection options are best and which components may need replacement from premature wear.

External leaks. External leaks allow the hydraulic fluid to inadvertently escape the system. Locating these leaks can be straightforward; other times it can be difficult because the leak’s source may not be in the location where the fluid gathers. Leaks can easily drip and travel depending on where they are on the machine.

External leaks can be formed due to failed seals, connections, hoses, or pipes. Whether it is wearing out a seal or creating a hole in a component, leaks are allowing air, moisture, and other contaminates to enter the system. These contaminants can lead to numerous problems, with the costliest being wasted fluid. It may seem straightforward to just keep topping off fluid levels, but that ends up doing more harm because the contaminates remain in the system, causing damage and wearing out components.

Additionally, there are safety and environmental factors to consider. External leaks can create hazardous conditions for operators and technicians. When left unattended, puddles or slick areas begin to form, leading to slippage or even fluid penetration-related injuries. A leaky outdoor hydraulic machine like a digger or an excavator could affect the environment. Fines and other serious consequences can result from fluid seeping into the ground.

Costs of leaking fluid

If several pieces of hydraulic equipment have multiple leaks, the accumulative cost over an extended period is alarming. The time spent for equipment repairs or adding lost operational fluid can cost thousands of dollars. When you factor in the indirect costs of wages, clean up, and disposal, along with lost production time, you can see how severely leaks may impact the overall bottom line. To initiate preventive care, inspect hydraulic equipment and mark all leaks for corrective action during the next service visit.

Preventive maintenance

Preventive maintenance is essential. It involves regular maintenance tasks to eliminate a reactive response to repairs. It has been proven that proactive routine care can help prevent equipment breakdowns, save on costs, and keep equipment running efficiently longer.

Preventive maintenance is essential. It involves regular maintenance tasks to eliminate a reactive response to repairs. It has been proven that proactive routine care can help prevent equipment breakdowns, save on costs, and keep equipment running efficiently longer.

To protect assets, it is important to implement a preventive-maintenance plan. Foundations of a maintenance plan should include regular inspections of the system’s hydraulic pressure, checking that fluid levels are at recommended settings and recording the status of each piece of equipment. A comprehensive list of preventive maintenance measures should be available from the OEM, from a service technician, or through a quick internet search.

Once procedures are established, make sure each maintenance task is updated and easily accessible by all employees, even nonmaintenance workers. This ensures that everyone is aware of what should be routinely checked and monitored. Procedures that are properly written and followed allow equipment to operate to its full potential and life cycle.

Fluorescent leak detection

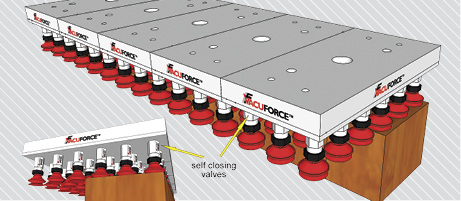

Fluorescent leak detection, also called UV leak detection, provides a quick, easy, and noninvasive solution for finding leaks in closed loop circulating fluid-based systems. A liquid dye compatible with the existing hydraulic fluid and machine surfaces helps determine whether visible fluid is from an active leak. In some applications with multiple fluid types, each fluid reservoir can be dyed a different color to clearly identify the source of the leak.

Fluorescent leak detection is compatible with fuel leaks, heat-transfer fluid leaks, hydraulic leaks, lubricant leaks, and refrigeration leaks.

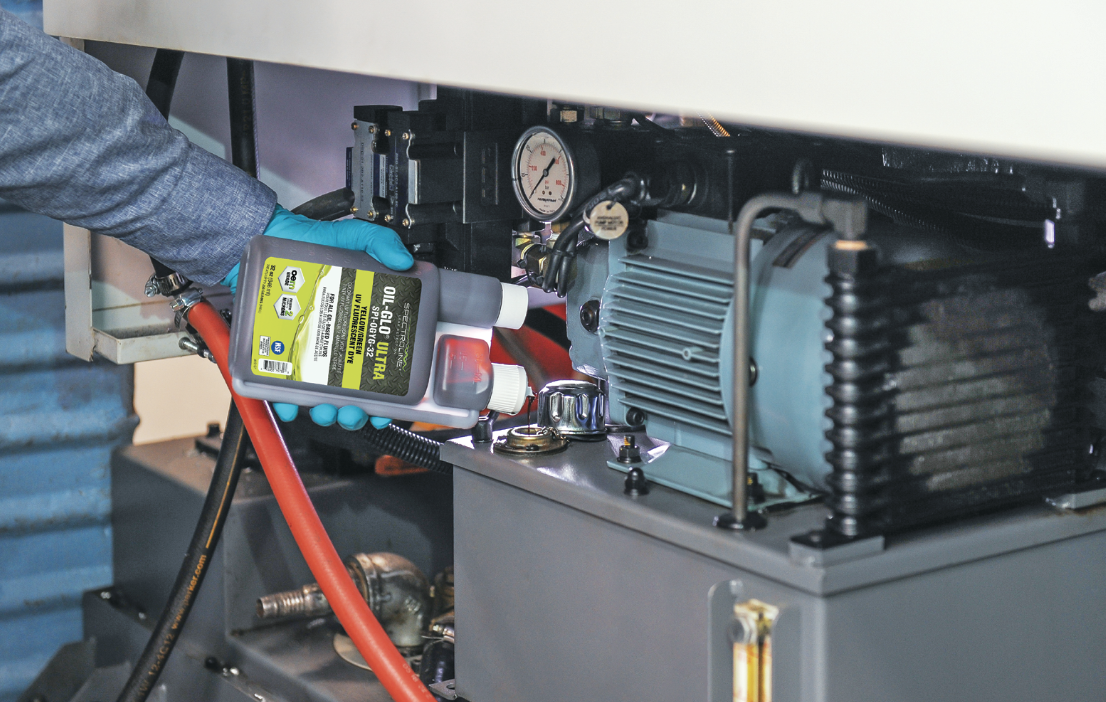

The leak detection process is simple. Based on oil ratio and the manufacturer’s specifications, a small amount of fluorescent dye is added to the equipment’s fluid reservoir. The dye mixes with the host fluid and circulates through the system. Depending on the system’s size, full circulation of the dye can take time.

Once fully circulated, the next step is to identify leaks. This requires a violet or ultraviolet flashlight. Violet and ultraviolet light fall within the 300-400 nanometer range, and these wavelengths easily activate the best fluorescent response in the dye particles. A technician simply scans the equipment with the flashlight. If there are leaks, the areas will be glowing, allowing a technician to diagnose the leaking system.

Benefits

Fluorescent leak detection is easy to incorporate into a preventive maintenance program. It is simple to use, visually intuitive, cost effective, and efficient for finding leaks. It enables technicians to safely scan near moving parts and easily detect the source of small or intermittent leaks. Additionally, it assists with future repairs because the dye can safely remain in the system.

Maintaining a sealed hydraulic system is essential to its safe operation and continued longevity. Constantly replacing lost fluid increases the chance of water and particulate contamination and results in higher operating costs. Leaks allow contaminates that affect the hydraulic fluid’s chemical properties to enter and degrade the system, leading to inefficiencies and ultimate operational failure. And leaks can add up – just one drop per second can result in 420 gallons of hydraulic fluid or more wasted in one year.

Fluorescent leak detection is a highly effective tool that maintains a smooth-running fluid system, prevents expensive equipment breakdowns, reduces labor costs due to downtime, and helps avoid environmental pollution and hazardous working conditions.

howdy-do, glorious blog on fatlike loss. said helped.

https://www.readyandroam.com/ready-and-roam/doorcounty/lizanne