Eaton Drives Efficiency with Hybrid Lift Truck Technology Test Drive

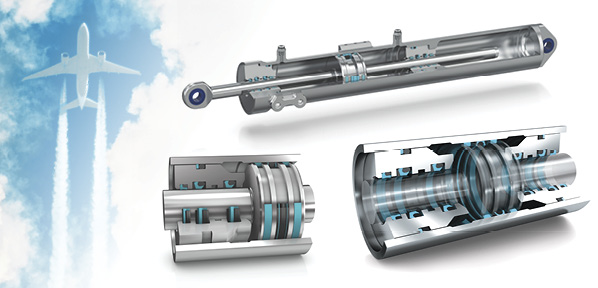

Eaton is moving lift truck technology to the leading edge with its new hydraulic hybrid solution. Engineers from the world’s leading lift truck manufacturers recently visited one of Eaton’s facilities in Germany to get a first-hand feel of this more efficient technology installed in a machine demonstrator.

“The hydraulic hybrid power system means cities and businesses can significantly reduce the amount of fuel consumed and emissions produced,” said Astrid Mozes, chief technology officer, Hydraulics Group, Eaton.

Lift trucks can carry the weight of the industry by moving goods from one place to another in distribution, logistics, warehouses, and manufacturing. In these environments, Eaton’s system helps improve energy efficiency, greenhouse gas emissions, productivity, operations cost, and safety.

The technology demonstrated up to 35% fuel savings when compared with a baseline vehicle. This improvement was achieved by enhancing system efficiencies and capturing energy from braking, then using that energy to supplement the engine’s power during acceleration. This reduces energy consumption, as well as improves carbon dioxide (CO2) and other emissions by 35% over a baseline vehicle.

For productivity, the system manages engine speed and torque, yielding optimal performance. The system also reduces conventional use of brakes, which means less wear and tear on this key machine component. It also addresses the engine start, replacing the function of traditional electric starters. The result is lower maintenance costs.

With this innovation, Eaton technologists have also simplified three operator inputs into one control lever for smoother and more efficient lifting, making it an easier machine to operate. Additionally, by simplifying inputs, Eaton’s system reduces the potential for operator error, leading to improved worker and operational safety.

Lift trucks and their operators are subject to tough conditions. Eaton’s hybrid power systems provide the value and technology to keep business moving.