On the Border

Boundary Lubrication in Cylinder Seals

By Andrew Iddeson, Global Technical Director, Hallite; and Chuck White, Director of Sales and Marketing, Hallite Americas

When it comes to hydraulic cylinder sealing systems, boundary layer lubrication is key to ensuring the longevity of the seals. However, as environmental and emission concerns grow, we should consider actual leakage versus factors in lubrication that contribute to the long-term effectiveness of seals and cylinders.

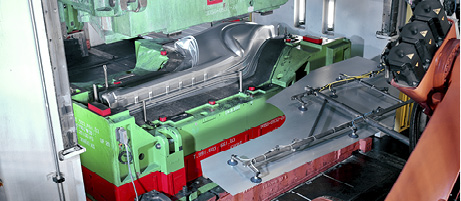

Boundary lubrication is a thin film of fluid that passes under the sealing lip, reducing friction and heat that contributes to wear reduction at the sealing lip. But given environmental and cost concerns, just how much boundary lubrication is acceptable? The answer depends on the application as well as the individual circumstances in which the seal is operating. For example, long-stroke cylinders used in applications such as cranes require a slightly higher level of boundary lubrication because the sealing elements cover more surface area during the cycle. Cylinders used in general mobile hydraulic applications such as aerial handling equipment require less boundary lubrication due to the cylinder’s size and duty cycle. Finding the right balance of boundary lubrication to promote seal life while meeting the application requirements can be challenging.

Finding the right balance

As we’ve said, boundary lubrication is an acceptable amount of fluid that passes under the sealing lip to promote seal longevity. This light film is carried in microscopic peaks and valleys in the surface finish of the dynamic hardware. The sealing lips of the seal conform to these peaks and valleys where the film of oil exists. If the peaks and valleys are too large, excessive boundary lubrication might be allowed to pass by the sealing lip. But insufficient peaks and valleys prevent the formation of the oil film, causing excessive wear. Seal profile also plays a role in balancing boundary lubrication. The correct seal profile at various pressures is key to making sure boundary lubrication is not cut off, which would result in frictional heat and wear at the sealing lip.

The industry uses several methods to assess the presence of boundary lubrication. The U.S.-based Society of Automotive Engineers developed the SAE J1171 standard to characterize the visual appearance of the boundary lubrication on rods in hydraulic cylinders. Though the standard is subjective, it provides a benchmark to assess and establish a level of boundary lubrication tolerable in a given application. This standard also provides guidelines to reference when experiencing an unacceptable level of boundary lubrication.

Although many national and international standards define methods for testing leakage in fluid power systems, few define acceptable leakage rates, preferring that users define their limits. However, one standard that does apply limits is JIS B 8354. This standard is challenging because it requires a collection of boundary lubrication samples or readings over a set number of cycles or distances, thus requiring longer monitoring periods for assessment. However, because JIS B 8354 defines acceptable leakage levels by classifying the application, it allows the user to confidently develop their own acceptance limits based on a volumetric measure according to cylinder size and end use.

Acceptable is subjective

Despite the two standards, opinions on the acceptable level of boundary lubrication vary and depend on the application. In general, Hallite uses several criteria when assessing acceptable levels of boundary lubrication.

When evaluating boundary lubrication using visual standard SAE J1171, levels of 0-2 are acceptable. Since all cylinders exhibit a “drip” of oil, the visual standard sets the boundaries of acceptable lubrication levels as guidance to identify potential concerns and issues with real-life examples per application.

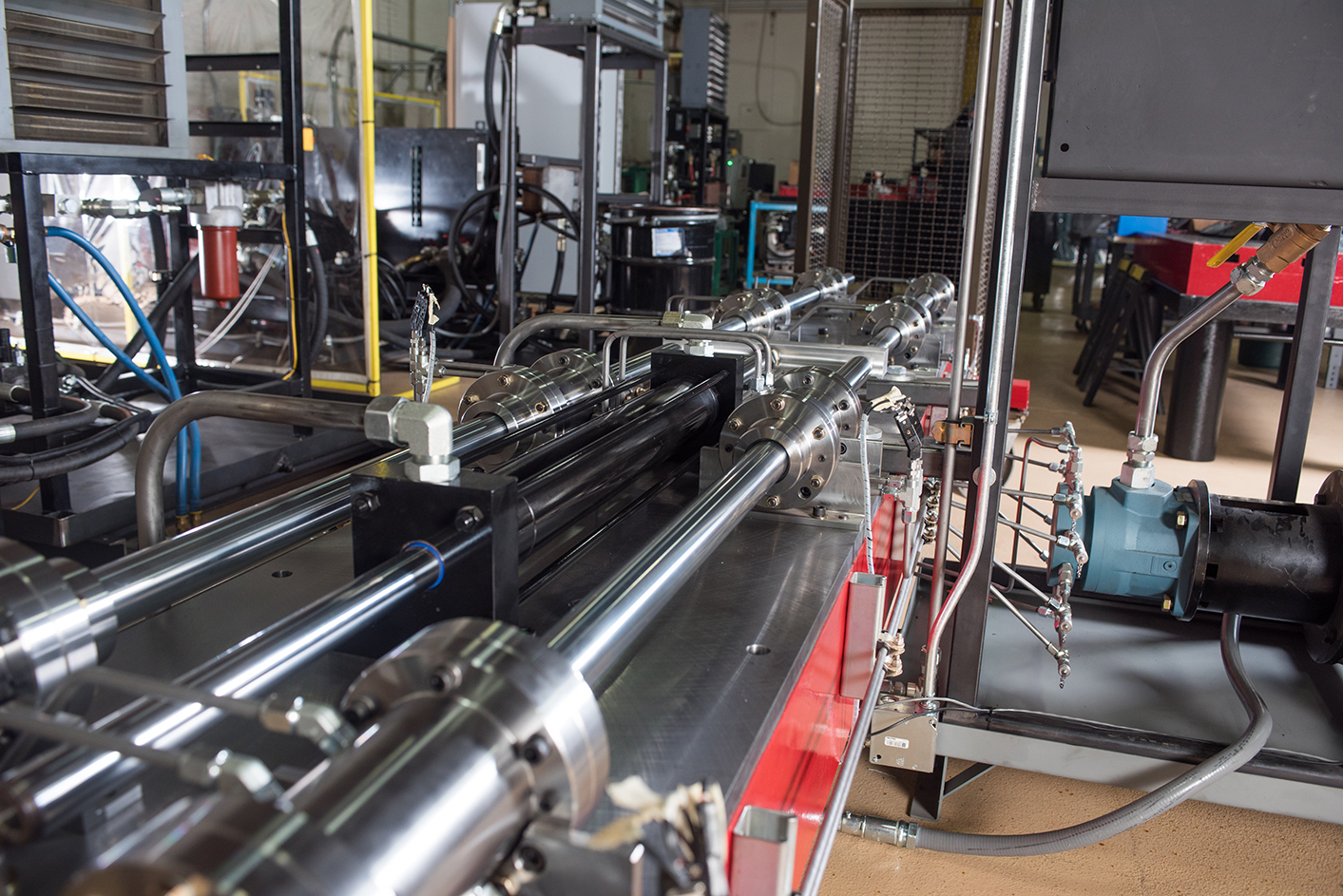

In class A leakage acceptance, the JIS 8354 standard is interpreted to show that on a 2-inch (50-mm) rod (as per Hallite testing), an acceptable limit should not exceed 0.05 ml per 100 m traveled. On the test rig, this equates to 20 ml over 50k cycles, the equivalent of 40 Km traveled.

An acceptable level of boundary lubrication or leakage is subjective. Though standards exist to provide guidance on recommended levels, the end application plays a huge role in setting the standard. Benchmark testing allows for data-based decision-making. Data collection based on real-life field conditions ensures compliance with set leakage standards such as JIS B 8354. It is difficult to offer data on every possible operating combination. However, with new technology in test equipment and methods, assessing seal performance is becoming easier in a lab setting.