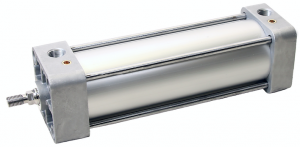

Emerson’s Aluminum Cylinder Boosts Machine Speeds

Emerson’s new AVENTICS TM5 TaskMaster aluminum cylinder promises to help machine builders and their end-user manufacturers increase machine speeds and reliability.

Emerson’s new AVENTICS TM5 TaskMaster aluminum cylinder promises to help machine builders and their end-user manufacturers increase machine speeds and reliability.

The National Fluid Power Association-compatible pneumatic cylinder reduces cost, energy consumption, equipment wear, and downtime, Emerson said in a press release.

With its rugged aluminum body construction and a steel piston rod, the TM5 TaskMaster features Emerson’s pneumatic cushioning technology that allows an ideal cushion adjustment to slow down the piston to a stop as it reaches the endcap. Ideal cushioning allows faster cylinder travel with reduced endcap hammer, providing an improvement in productivity by significantly boosting machine speed. Ideal cushioning. Ideal cushioning enables the TM5 cylinders to carry higher loads without sacrificing cylinder performance. The cylinder incurs less stress and there is no end-of-stroke bounce or end-cap slamming, which is a main source of cylinder wear, slowness and noise, Emerson said in the release.

The TM5 TaskMaster is supported by a suite of web-based design and integration tools, with many products preconfigured and ready to order. With no additional engineering time for setup, Emerson’s online configurator provides a product part number, pricing and 2D and 3D CAD drawings in one convenient place. Product information and spare parts can be found in the AVENTICS Pneumatics Shop.

For more information, visit: www.aventics.com/taskmaster.