Enhancing Forestry Safety

Elements of this image furnished by Adobe Stock | CaptureAndCompose

By Justin Mahendra, Director of Sales and Product Management, Sure Grip Controls.

It is no secret that forestry operations present many unique challenges that demand robust and reliable solutions to guarantee safety in the field.

It is no secret that forestry operations present many unique challenges that demand robust and reliable solutions to guarantee safety in the field.

There are complexities involved in navigating through harsh weather conditions. These include managing intricate and often unpredictable terrain, as well as operating sophisticated hydraulic machinery. These intricacies introduce many risks that cannot be overlooked. In this context, the development and implementation of tailored control solutions emerges as a critical factor in enhancing operational safety and streamlining processes. This significantly mitigates the risks faced by operators.

For forestry professionals, safety managers, and equipment manufacturers, the challenges encountered in the day-to-day operations of forestry work are deeply understood. Extreme weather conditions, ranging from high winds and heavy rainfall to snow and ice, can significantly compromise machinery visibility and performance. This creates hazardous working conditions for those on the ground navigating these dangers while performing their duties. The complexity of the terrain, which can often be uneven, steep, and unstable, heightens the likelihood of accidents. This unpredictability reinforces the need for precise, dependable, and adaptable control systems that respond to changing environmental conditions and terrain challenges with ease.

Regardless of any other variables, the handling of fluid power machinery in and of itself requires accuracy and expertise to minimize errors and ensure overall safety during operations. The precision with which these machines must be controlled cannot be understated – a single miscalculation can lead to significant safety incidents, potentially resulting in injury or even loss of life.

Addressing these multifaceted challenges often calls for specialized solutions tailored to withstand the demanding environments that are characteristic of forestry operations. These solutions must be designed with an intimate understanding of the operational context, incorporating advanced technology and innovative design principles to meet precise industry standards. Only through tailored, sophisticated control solutions can the forestry sector hope to strike a balance between operational efficiency and safety.

The bottom line is forestry operations present unique challenges that necessitate robust and reliable solutions to ensure both safety and efficiency. In this context, tailored control solutions emerge as a critical factor in enhancing operational safety, streamlining processes, and mitigating operator risks. Addressing these challenges calls for specialized solutions tailored to withstand the demanding environments characteristic of forestry operations.

A Case Study

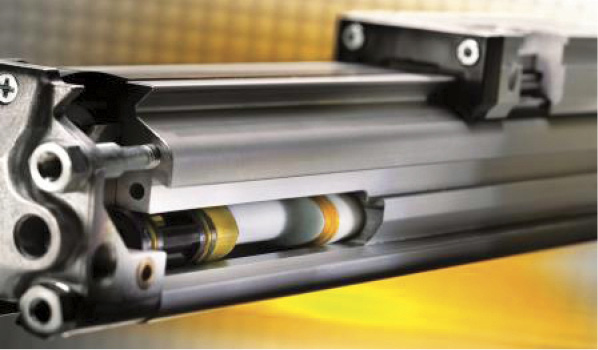

A prime illustration of a solution crafted to cater to the specific needs of forestry operations is the LU Handle by Sure Grip Controls. This specialized control grip stands out due to its deliberate design. It is engineered to include features that directly tackle the challenges identified by professionals in the field.

The LU Handle stands out in the forestry equipment market because it’s highly customizable. The core of its innovation lies in the control unit, which allows for the seamless integration of multiple switches. This capability enables equipment manufacturers to configure the Handle in ways that perfectly align with unique operational requirements, offering unparalleled adaptability and precision in control.

The Handle is constructed from advanced high-impact plastic polymers, which prioritizes operator comfort during extended periods of use. This focus on ergonomics significantly reduces the risk of fatigue, ensuring that operators can perform their tasks with less strain. The benefits of the design are twofold: it enhances safety by minimizing the potential for operator error due to discomfort, and it increases overall productivity by allowing for longer, more comfortable working periods.

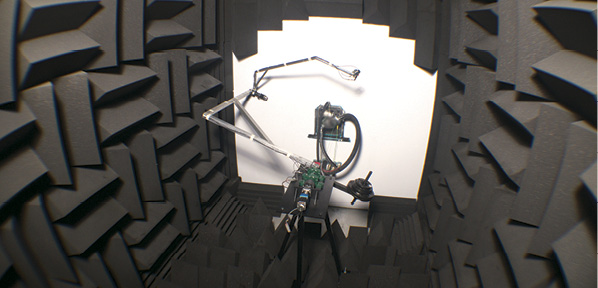

Additionally, the LU Handle boasts an impressive degree of durability. Its robust sealing meets IP67 standards, offering top-tier protection against the ingress of dust and water. This feature is crucial for ensuring reliable performance under the demanding conditions often encountered in forestry operations, where exposure to the elements is a constant challenge. The Handle’s durability is evidenced by rigorous testing protocols, which confirm that the switches can withstand millions of operations without failure. This level of durability extends the Handle’s life and contributes to a reduction in maintenance costs and downtime.

The versatility of the LU Handle is another key element that sets it apart. It can be adapted for use across several types of machinery within the forestry sector. This adaptability makes it an invaluable tool for forestry companies that rely on a diverse array of equipment in their daily operations.

Collectively, these features—the customizable control options, exceptional durability, and versatility—contribute to a significant enhancement in safety, efficiency, and operator ease. The LU Handle exemplifies a broader trend leaning toward the integration of sophisticated technology in forestry equipment. This reflects a commitment to improving not only the performance of machinery but also the working conditions of those who operate it.

The Broader Trends

The LU Handle’s capabilities represent a significant milestone in overall forestry technology evolution. This evolution is characterized by innovations in control systems that are progressively enhancing the functionality of fluid power machinery, leading to improvements in operational safety.

One of the most noteworthy advancements in this area is the adoption of automation technologies. Automation is quickly becoming a defining feature of modern control systems, with its aim at minimizing human error and maximizing precision. By integrating autonomous functions, these systems can effectively manage repetitive and high-risk tasks, thereby allowing operators to focus their attention on more complex decision-making.

This shift towards automation has profound implications, primarily because it significantly reduces the exposure of personnel to potential hazards in the workplace. Furthermore, modern control systems are increasingly incorporating real-time monitoring and data analytics capabilities. It’s now possible to perform continuous assessments of hydraulic machinery health and performance using sensors and connectivity features. Leveraging these data analytics tools enables forestry professionals to accurately anticipate maintenance needs and prevent unexpected machinery breakdowns, issues that often lead to costly downtime and disrupt operations.

These technological advancements are pivotal to enhancing safety and efficiency in future forestry operations. These innovations elevate control systems to a place of critical importance, making them indispensable in the pursuit of operational excellence.

The robust and reliable control mechanisms offered by the LU Handle demonstrate how well-designed control systems can mitigate risks associated with challenging environmental conditions and complex operational tasks. The reliability and consistency provided by such systems empowers operators to perform their duties with increased confidence, ensuring they can adeptly navigate the myriad challenges presented by forestry work.

Consistent performance is especially vital in an industry where unpredictability is a common occurrence. Features such as tailored switches and customizable controls provide a familiarity that can improve reaction times during emergencies, significantly reducing the risk of accidents.

The integration of advanced control solutions is essential to effectively address the complex challenges associated with forestry operations. By enhancing safety, improving efficiency, and welcoming technological innovations, these solutions empower forestry professionals to attain superior operational outcomes.

As the forestry industry continues to evolve, embracing the advancements in control systems will be vital to ensure a progressively safe working environment. Industry professionals are encouraged to collaborate with expert teams specializing in control systems for forestry operations. These teams can provide valuable insights and customize control systems to further enhance safety and operational efficiency. By prioritizing well-engineered solutions, the forestry sector will continue its trajectory toward improved safety and efficiency.