Ensure Temperature and Viscosity Compatibility

The temperature at which the fluid is to be working must be considered. At elevated temperatures, high water based fluids may lose water as it evaporates and will need to be continually monitored and replenished. The same fluid may become useless at cold temperatures because of high viscosity or freezing. A fluid must be chosen that has a viscosity range and proper lubricity for the environment in which it will be working.

Temperature is often the controlling parameter (when choosing a fluid). No single fluid meets all the performance requirements in even a single range of temperatures. The truth is that the designer must sacrifice some “important” characteristics to achieve “essential” characteristics.

Viscosities are low at the higher temperatures, and oxidation will deteriorate the oil in open systems. However, both closed systems and proper bearing and seal design help solve both problems.

Most problems are magnified as temperatures rise. Mild fluids become corrosive when hot; stable fluids break down into useless new compounds.

Some pumps and motors are limited by fluid viscosity and lubricity and must be de-rated if low viscosity or high water content fluids (HWCF) are used. The right pump and/or motor must be chosen for the fluid being used or the right fluid must be chosen for the pump and/or motor that is specified.

To adequately carry out the previously stated purposes, the fluids used in hydraulic systems must possess, to varying degrees, specific desirable characteristics. Not all fluids will have all of the necessary attributes in equal strength. Consequently, when selecting fluids it is sometimes necessary to compromise some properties in favor of others that may be more important for a specific application requirement. In general these properties include: viscosity and viscosity index, pour point, lubricating ability, oxidation resistance, compatibility with system elements, rust and corrosion protection, and demulsibility.

The viscosity of a fluid may be defined as its resistance to flow at a given temperature. If a fluid flows easily, its viscosity is low. A fluid that flows with difficulty would be said to have high viscosity. It has more resistance to flow than the lower viscosity or “thinner” fluid.

Viscosity affects the fluid’s ability to be pumped, transmitted through the system, carry a load, and maintain separation (lubrication) between moving surfaces. The selection of proper viscosity is often a compromise in order to optimize system performance. Too high, or too low a viscosity for a given system, could present problems of performance, leakage, energy usage, and so forth.

Viscosity too high (fluid is too thick):

- High resistance to flow.

- Increased energy consumption due to increased friction, and increased input requirement at the pump.

- High temperatures created by power lost to friction.

- Increased pressure drop (ΔP) due to increased resistance to flow.

- Slow or sluggish operation/actuation.

- Inefficient separation of air from the oil in the reservoir.

- Pump cavitation.

Viscosity too low (fluid is too thin):

- Increased internal leakage.

- Excess wear. Seizure, particularly of pumps, could occur under heavy load of a breakdown in lubrication film between the clearances of moving parts.

- Decreased pump efficiency (volumetric) due to increased leakage and possible cylinder blow-by. This could cause increased cycle times or slower machine operation.

- Internal leakage, causing an increase in operating temperatures

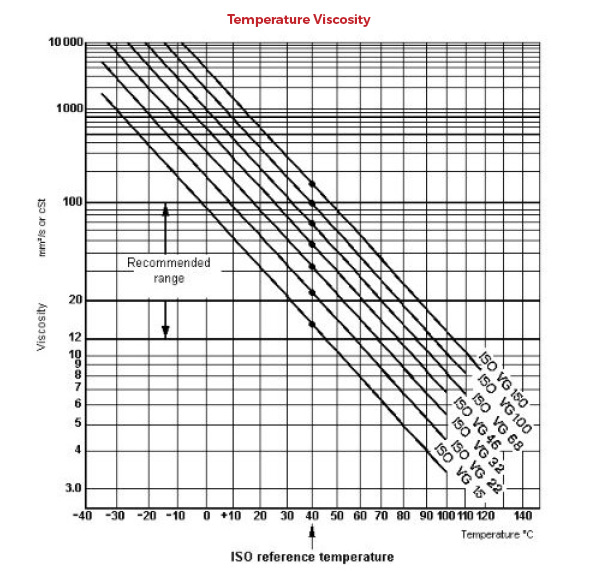

There are numerous methods for defining viscosity. Among these are: absolute or dynamic viscosity (centipoise/cP), kinematic viscosity (centistoke/CST) and relative viscosity as measured in Saybolt Universal Seconds (SUS or SSU). Most hydraulic systems run with oil in the range of 150 to 300 SUS with typical ISO viscosity grade (ISO-VG) range of ISO-VG-22 to -68.

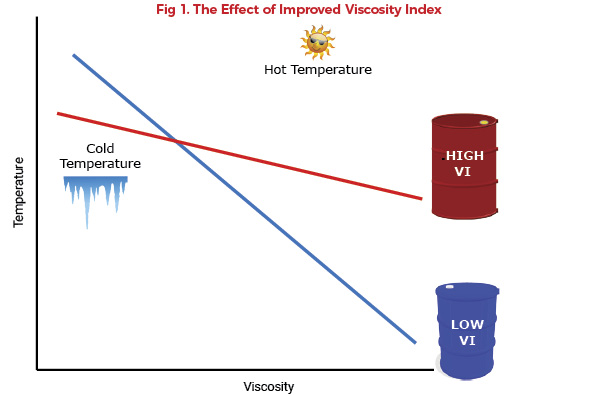

The viscosity of virtually all fluids used in hydraulic systems is affected by variations in temperature. Viscosity Index or VI is an arbitrary number that characterizes the variation of viscosity of a fluid with variations of temperature. Simply put, the higher a fluid’s VI number, the less change there is in the fluid’s viscosity over a given range of temperatures as shown in Fig. 1.

Multiple viscosity oils typically include additives (polymers) to improve the viscosity index. These oils can exhibit both temporary and permanent decreases of viscosity due to oil shear during hydraulic machine operation. Consequently, multiple viscosity fluids with high shear stability are desirable. The viscosity of hydraulic fluids, particularly petroleum-based fluids and vegetable oils, is directly and sometimes adversely affected by changes in temperature. For this reason, it is essential that the startup and operating temperatures of mobile machinery be monitored. To insure proper lubrication, machinery should not be put into high speed or heavily loaded operation until the system fluid is warmed up to the operating temperature.

Arctic conditions will cause an increase in viscosity that could result in pump cavitation and severe damage to the hydraulic system at startup. Many hydraulic components for mobile applications are designed with cold starting conditions taken into consideration and offer some protection against cavitation until the fluid is warmed to operating temperatures. Unless otherwise indicated by the manufacturer, mobile machinery is typically run at idle until satisfactory operating temperature is attained.

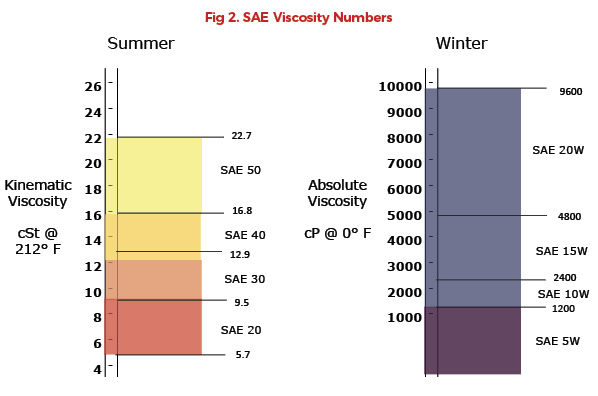

Excessive heat in a system can cause a reduction in viscosity. This will result in severe wear due to a loss of lubricity as well as the destruction of the fluid through oxidation. Severe oxidation, in turn, may cause the fluid to thicken by causing varnish, sludge, corrosive acids, and the destruction of additives. The Society of Automotive Engineers (SAE) has established numbers to specify ranges of viscosity for engine oils at specified test temperatures, illustrated in Fig. 2. Winter numbers (0W, 5W, 10W, 15W, etc.) are specified viscosity ranges at cold temperatures. Summer oil viscosity numbers (20, 30, 40, etc.) are measured at 212°F.

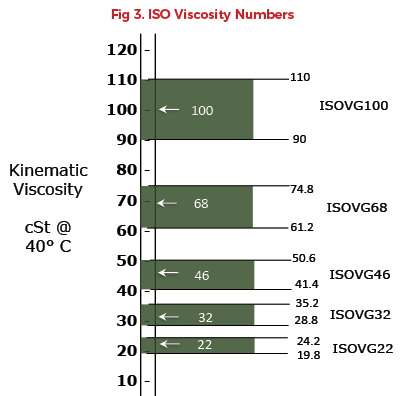

International Standards Organization (ISO) viscosity grades are shown in Fig. 3. The ISO viscosity grade number represents a range of kinematic viscosity values at 40°C (104°F), and is the midpoint number of the range. The ISO designation is becoming more popular, and many fluid suppliers are incorporating the designation in their brand description.

International Standards Organization (ISO) viscosity grades are shown in Fig. 3. The ISO viscosity grade number represents a range of kinematic viscosity values at 40°C (104°F), and is the midpoint number of the range. The ISO designation is becoming more popular, and many fluid suppliers are incorporating the designation in their brand description.

A useful tool, particularly with mobile equipment exposed to radical changes in temperature, is to obtain occasional verifications of a fluid’s adherence to its specified viscosity. Of course, this specified viscosity should be defined within the operating parameters of the application. When viscosity analysis is used as a fluid monitoring tool, realize that the actual viscosities of new fluids can vary somewhat from their specifications. Consequently, changes in viscosity over a period of time are usually considered more important than an actual reading. Changes of more than 10% from the original reading are considered an indication of problems.

Test Your Skills

1. Viscosity is defined as:

a. Having consistent thickness throughout a temperature range.

b. Resistance to flow at a given temperature.

c. The stiction of the fluid.

d. The pour point of the fluid.

e. The evaporation point of the fluid.

2. What is the reason for knowing the chemical compatibility?

a. Increased energy consumption.

b. Higher temperatures in the fluid.

c. Difficulty of air separation.

d. Potential cavitation.

e. None of the above.

What is the correct solution?

1.b, 2.e