Festo Launches ‘Reimagined’ Valve Position Control

Festo recently launched “reimagined” pneumatic process valve position control through the combination of the new CMSH smart positioner and the integrated mounting possible with the new VTOP modular installation platform, the company said in a press release.

The CMSH contains a host of features, including HART communications protocol as well as integrated safety functions that can provide customers with up to 30% in savings. The attach-and-play VTOP ‒ with any combination of filter regulator, booster, or fail safe ‒ eliminates the time, expense, and risk of plumbing add-ons to the process valve assembly and can provide an additional 30% savings on the installation process.

Festo also provides the benefit of one point of contact for world-class process valve assemblies and solutions, including online configuration tools that lower engineering overhead.

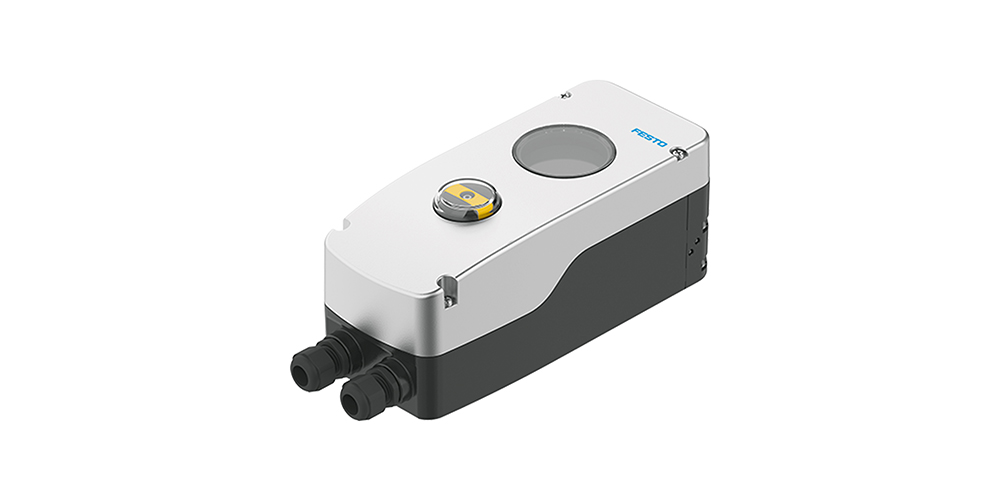

CMSH smart 2-wire positioner

The CMSH delivers a highly dynamic, low-wear positioning system with high air output and a long service life. The positioner is designed for fast precision control of actuators – large or small, linear or rotary, and single-acting or double-acting. CMSH features 2-wire technology (analog and digital), HART communication, condition monitoring, fail safe modes, and a modular system with many variants. With an ambient temperature range from -40°C to 80°C (-40°F to 176°F), it is suitable for applications in the chemical industry, mining, and mineral processing, and in the fields of energy, biotech, pharmaceuticals, cosmetics, water, and bulk goods.

An onboard setup wizard for common application parameters allows fast, efficient, and easy commissioning and initialization. Integrated pressure sensors provide intelligent diagnostic functions, including continuous monitoring of breakaway pressure, pressure-assisted partial stroke tests, and reliable leak detection. Status messages – such as failure, outside specification, function test, and maintenance required – can be viewed on the CMSH liquid crystal display or via remote device.

The CMSH also features numerous configuration options for different applications, including the addition of onboard pressure gauges for additional pressure monitoring, digital end-position feedback, and a bank of unassigned inputs and outputs that give the user the freedom to add functionality. CMSH can be ordered for single-acting or double-acting actuators and can also be customized via an exchangeable sub-base so that one model can serve many applications.

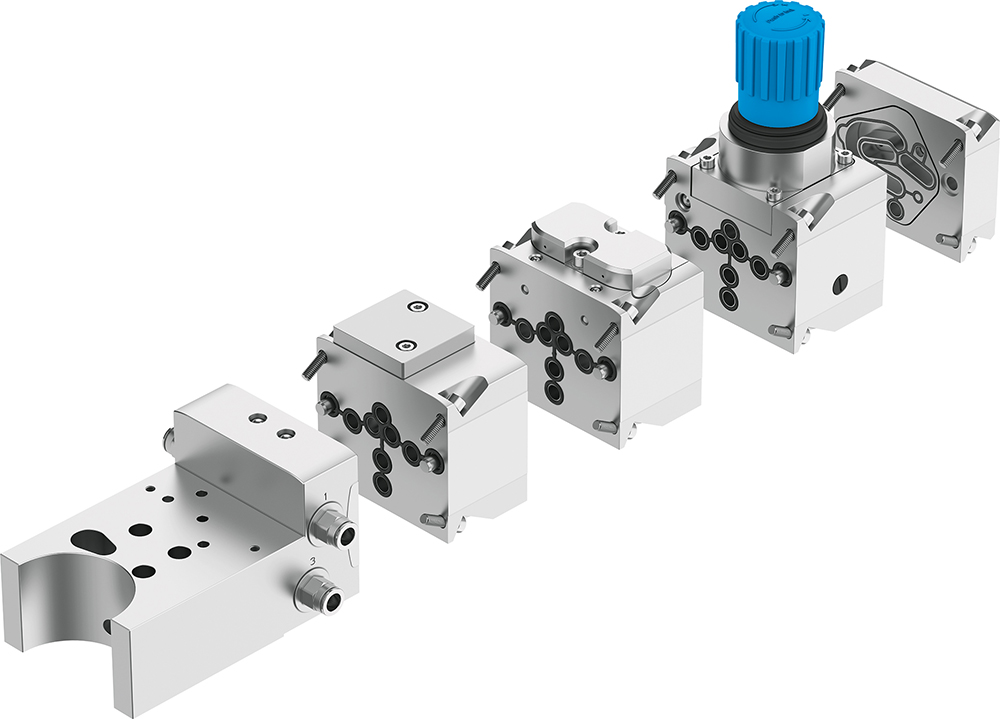

VTOP modular installation platform

Process valve assemblies consist of the valve, quarter-turn actuator, and, many times, a positioner. Often the three-unit solution requires additional components because of the need for air boost, safety venting, air filter, or pilot valves. The VTOP platform makes it fast and simple to add any combination of these functions through a series of attach-and-play modules. VTOP eliminates the need for external piping that takes time, adds to the footprint, and is susceptible to faults and leaks.

The modular design of the VTOP, which features patented, integrated air routing, enables the individual modules to be combined as needed for the customer’s specific requirements. VTOP modules can be extended and retrofitted at any time. The platform is more compact than conventional solutions in which the individual components connect by pipes in a complex process – a pneumatic control board, for example. VTOP modules feature VDI/VDE 3845 and 3847 one- and two-component mounting plates.

For videos, see CMSH video and VTOP video. For more information, visit www.festo.com.