Knowing Where to Look for Contamination

Proper training in preventative maintenance reduces system failures.

By Sam Kaye, CFPS, CFPSD, Applications Manager, RHK Hydraulic Cylinder Services

The maintenance department is the cornerstone of any company that relies on equipment to generate profit. Workers may toil in relative obscurity until an equipment failure casts a glaring spotlight on the maintenance department’s ability to get that machine up and running again, a task that can involve everything from senior tribal knowledge to trial-and-error parts swapping. Production losses have an immediate negative impact on the bottom line, and the urgency that arises from a breakdown is palpable.

A maintenance department that is plagued with breakdowns can spend most or all of its time running from one problem to the next. This can become a vicious cycle of failures due to a lack of preventative maintenance that can’t be completed because the resources are tied up dealing with breakdowns. It’s not only frustrating for everyone involved but counterproductive in every sense. There are many components within the maintenance department’s scope of responsibility: electrical, mechanical, pneumatic, and – the focus of this article – hydraulic systems.

I’ve had the opportunity to work on a variety of hydraulic equipment over the years in sectors including industrial plants, agriculture, construction, and oil and gas. Each sector is unique in its own way, but one thing that remains constant across all industries is that the leading cause of component failure in hydraulic systems is contamination. I’ve heard estimates of contamination higher than 80%. That’s a huge number to be attributed to a single issue. When you consider that the cost of production loss is often higher than the cost of repairing the hydraulic system, downtime for controlling contamination starts to make sense.

I once worked for a company that handled repairs for a large meat-packing plant. It employed hundreds of workers, and its huge plant ran 24 hours a day. It was such a large-scale operation that they measured downtime in thousands of dollars per minute. If something as simple as a $300 hydraulic motor on a conveyor failed, it could cause a ripple effect throughout the whole plant. Even if they had a spare motor and could swap it out in 20 minutes, it would still cost the company $40,000 because they had hundreds of workers doing nothing during that downtime. Production losses were enormous.

While not every company loses thousands of dollars a minute, every company loses something when its equipment breaks down. Whether from loss of production, damage to the company’s reputation, or even loss of contracts, the financial impact of equipment failure is usually much higher than the cost of the repair to the hydraulic system. It’s easy to pull a financial report that indicates costs allotted to the GL code labelled “hydraulics,” but that’s only part of the story. It’s important to consider this when you are assessing the true costs that are associated with contamination-related failures.

That’s the bad news about contamination in your hydraulic system. The good news is that companies can get contamination under control and see an immediate decrease in numbers of failures. It starts with recognizing that there are two components to success – the machine component and the human component.

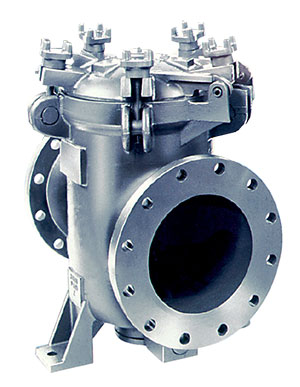

The machine component involves assessing the hydraulic system to determine what the cleanliness target should be and ensuring that the system’s components can achieve and maintain that target. If the hydraulic components aren’t capable of controlling contamination, then it doesn’t matter what maintenance people do; they won’t be successful. They need to be assured of success before launching the program.

Assessing the hydraulic system is critical, and it’s important that a fluid power professional who fully understands the aspects of the system that factor into contamination control complete the assessment. The assessment examines factors such as the sensitivity of the system’s components to contamination, the working pressure of the system, the type of environment, and the type of fluid used in the system. Each hydraulic system is unique and must be assessed individually. Even separate hydraulic systems located within the same plant may have vastly different requirements.

After completing the assessment and making any required changes, the human component comes into play. This involves developing equipment-specific training for the operational and maintenance groups. It’s important to involve both of these groups in the training because each has a vested interest and a role to play in keeping the equipment running smoothly.

Some companies slip into the trap of allowing the operational group to run the equipment until it fails, and then it becomes the maintenance group’s problem. Avoid this scenario. Number one, it’s dangerous. Lack of planning for unexpected breakdowns leads to rushing through tasks, missing steps, and even intentionally cutting corners to get the equipment back up and running. The workplace incident rate is much higher when workers are involved in breakdown repairs. It’s also expensive. Calling suppliers after hours to buy parts leaves no room for negotiation. You pay whatever they charge you, including higher rates for after-hours service calls. This scenario is counterproductive. There is no advantage to having an emergency repair department running around trying to “quick fix” equipment.

It’s important that the operational and maintenance groups work as a team. The goal isn’t to make fluid power experts out of the groups; it’s to give them equipment-specific training so they have the tools they need to succeed at taking care of the fundamentals.

For the operational group, training means a better understanding of how the hydraulic system operates, including a closer look at the inner workings of specific components like filters. People are more likely to identify abnormalities if they understand how something is supposed to work. A simple daily checklist for the operator will help identify issues when they are minor and can be brought to the attention of the maintenance group. Once you have these two groups taking care of the basics, many bigger problems never materialize – and neither do the costs associated with them.

Let’s look at an example. Let’s say that Lisa operates a hydraulic press in a large plant. She goes through her daily checks and notices that the clogging indicator on the return filter is nearing the end of the green zone. Because Lisa has had some training and knows how the filter system works, she recognizes that the return filter is nearing its dirt-holding capacity and will soon go into bypass. She notes this on the checklist, which triggers a work order for the maintenance group. Now the maintenance group can pull the correct filter, review the JSA, and replace the filter at the next shift change. That’s maintenance! It’s planned, safe, and cost effective. And the best part is that the cleanliness of the hydraulic fluid is never compromised. The team maximized the filter’s service life without risking a spike in contamination from running the filter in bypass.

For the maintenance group training means hands-on coaching on collecting oil samples and interpreting the results. I cannot overstate how critical this step is to the success of the program. Any corrective actions or changes to maintenance procedures are based on the results of the lab analysis. If the sample is low quality the program is low quality. Garbage in = garbage out. The cost of poor oil samples can be enormous in dollars and resources.

I know of a company that spent thousands of dollars and hundreds of man hours trying to address water contamination in the hydraulic systems of multiple units. In an effort to bolster a preventative maintenance initiative, the company had implemented an oil-sampling program and instructed all maintenance personnel to send in regular samples for analysis. When managers reviewed the sample results, they found that dozens of units within the same geographical area regularly tested positive for water contamination. The company hired another firm to travel to each location and either filter or replace the oil at a cost of $4,000 to $10,000 per unit. Within a few weeks the problem resurfaced and the process began again. By the time I was consulted more than a year later, the company had spent over $500,000 trying to keep water out of the hydraulic oil.

I began by visiting each location and asking the maintenance personnel to show me how they pulled the oil samples. Each one walked to the drain valve on the bottom of the reservoir, cracked the ball valve, and filled the sample jar. As water is heavier than oil, it settles to the bottom of the reservoir, right next to the drain port. Since the laboratory measures water in parts per million, even a droplet of water formed by normal condensation would cause the sample results to come back “positive severe” for water contamination. Once we installed sample ports in the correct locations and properly trained maintenance personnel how to take samples, each unit’s water contamination problem went away. The company had spent over $500,000 trying to fix a problem it never had!

There are several ISO standards to which you can refer for guidance on correct sampling techniques, understanding particulate coding, and contamination control principals.

- ISO 3722: Hydraulic fluid power – Fluid sample containers – Qualifying and controlling cleaning methods.

- ISO 4021: Hydraulic fluid power – Particulate contamination analysis – Extraction of fluid samples from lines of an operating system.

- ISO 4406: Hydraulic fluid power – Fluids – Method for coding the level of contamination by solid particles.

- ISO/TR 15640: Hydraulic fluid power contamination control – General principles and guidelines for selection and application of hydraulic filters.

The fluid power professional who assessed the system can provide guidance on establishing parameters for flagging the results. This not only relates to the particle count, but also to the total acid number, viscosity, water, and so on. These parameters are unique to each system, and what is normal for one might be flagged as unacceptable or severe for another.

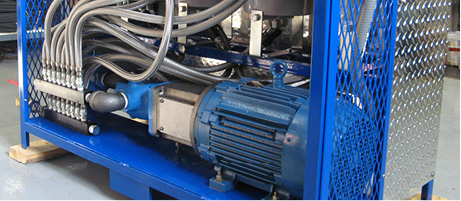

I’ve designed hydraulic systems for drilling rigs in the oil and gas industry, which is one of the harshest environments you can imagine. I’ve also designed training for the operational and maintenance groups, including proper oil-sampling techniques and interpreting results. Some of these rigs have been working in the field for more than seven years and are still running the original piston pumps. They are also achieving cleanliness codes of 15/12/9. Anyone who is familiar with ISO 4406 knows that’s aerospace clean. It’s no coincidence that systems with clean oil also have components with an extended service life.

Controlling contamination in a hydraulic system is one part of a preventative maintenance program. It pays dividends immediately, and it does so for the life of the equipment.

One thought on “Knowing Where to Look for Contamination”