Fire-Resistant Hydraulic Fluids: Cost vs. Benefits

A large automotive components manufacturer had a series of fires on its hot stamping lines—all caused by oil from ruptured hoses or leaky couplings that ignited when the oil came into contact with the hot metal being formed. In 2012, a particularly bad fire injured workers and caused 12 days of downtime, resulting in £5.3 million in damages from lost production and repairs. After assessing all the options—including changes to the sprinkler systems and equipment design—management concluded the safest and most cost-effective approach would be to replace the highly flammable mineral oil with a synthetic, water-free hydraulic fluid (HFD-U). This conversion was a significant outlay—approximately £70,000. So why did management believe avoiding future fires was worth that much additional expense?

Mineral Oil—Large Operators Say Too Much is at Risk

Today, in manufacturing operations that pose a risk for fire or explosion, most large-scale manufacturers have already replaced mineral oil with fire-resistant hydraulic fluids. Even though these fluids can cost anywhere from two to four times as much as mineral oil, the economics are sound for these producers because with mineral oil, there is simply too much at risk.

Fires not only cause an unsafe workplace; they also damage the manufacturer’s bottom line and reputation. Fires can cause

- Loss of capital due to loss of production and costly repairs (hoses, seal, and even full equipment replacement)

- Loss of ability to deliver components, which can result in diminished customer trust in a company’s ability to supply parts on time

- Injury or loss of life

So when these larger, global producers decide to convert, they consider this wide range of issues. While product price is a factor, it’s only one of many. A great deal of consideration goes to “soft” issues that help uphold the company’s brand and reputation—including their commitment to customers, employees, the environment, and shareholders.

All Manufacturers Should Take a New Look

Many manufacturers are experiencing a weakened economic environment. So discussions on spending more on anything, including fire-resistant hydraulic fluids, are usually not at the top of anyone’s list…unless there is a fire.

A fire can be devastating to a producer, and even more so in these difficult times. Waiting until there is a fire to review fluid options is not a wise choice. And because the economics, regulations, and technologies related to hydraulic fluids are always changing, it’s best to evaluate hydraulic fluids periodically, reviewing all the issues to determine if converting to a fire-resistant fluid makes sense for the facility.

How to Choose—There’s No One Right Answer

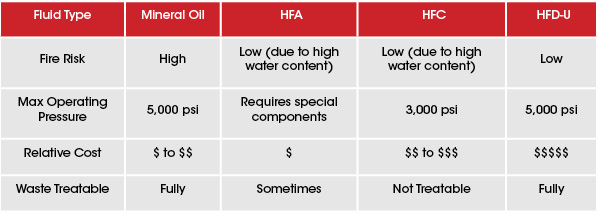

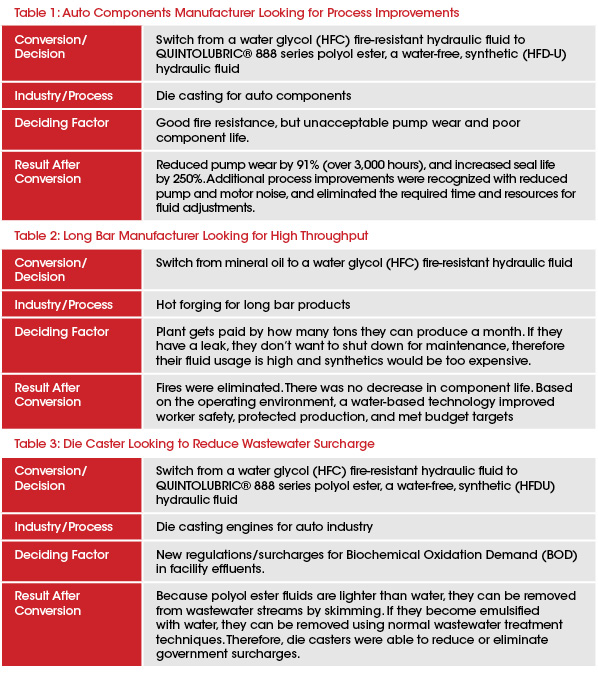

Globally, there are two types of fire-resistant hydraulic fluids that are dominant in high-temperature operating environments: water glycols (HFC) and polyol ester (HFD-U)-based fluids. The relative benefits of each technology are different for each situation. Every company, every facility has a different set of demands to respond to—demands placed by regulators, customers, and the economy.

A supplier with broad experience in a wide range of facilities and processes can help the producer explore possibilities and aid in the decision process. Tables 1-3 include three short examples of decisions customers made about their fire-resistant fluid technology after thorough analysis.

When evaluating hydraulic fluid options, it is important for the manufacturer to pull together an internal team of stakeholders so all business issues can be considered and brainstormed. Within some companies, silos develop that impede the right overall decision. Each department has a specific focus, such as

- Safety and human resources: the lowest risk fluid

- Maintenance department: the fluid for higher productivity

- Waste treatment department: the best fluid to reduce waste treatment costs and surcharges

- Operators: the least expensive fluid

For a thorough evaluation, a qualified supplier will help unify and support a 360-degree view of all the issues (Table 4). Preferably, this supplier will understand the specific processes and all the goals for the customer’s bottom line. A good supplier should be able to present several recommendations—each with pros and cons. Ultimately it is up to the customer to decide how to balance the benefit/cost equation.

At Quaker Chemical, here is how we approach and evaluate hydraulic fluids:

- We start by walking through the full process. We look at the hardware, layout, pressures, and environment.

- We analyze the equipment: the OEM recommendation, operating pressures, cleanliness, processing speed, and load demand.

- We examine the fluids: the current fluid and usage compared to similar customers.

- We check out the wastewater: the geographic location and proximity to metro area. We then proceed to onsite or outside, regulations, and current costs/surcharges.

- We analyze conversion. This can be from mineral oil to water glycol, which is a longer process, involving draining, flushing, and refilling. The mineral oil to HDF-U conversion is a shorter process of topping off, draining, and refilling. There is no need to flush the system.

- Finally, we suggest the best options for hydraulic fluid type and a specific product.

For more information: Peter Skoog is technical manager – fluid power and grease, for Quaker Chemical Corp., a global provider of process fluids, chemical specialties, and technical expertise to a wide range of industries, including steel, aluminum, automotive, mining, aerospace, tube and pipe, and cans. Visit www.quakerchem.com.